Soldering method, soldering device, bonding method, bonding device, and nozzle unit

A brazing method and brazing technology, applied in brazing, can solve problems such as nozzle 402 opening 403 blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

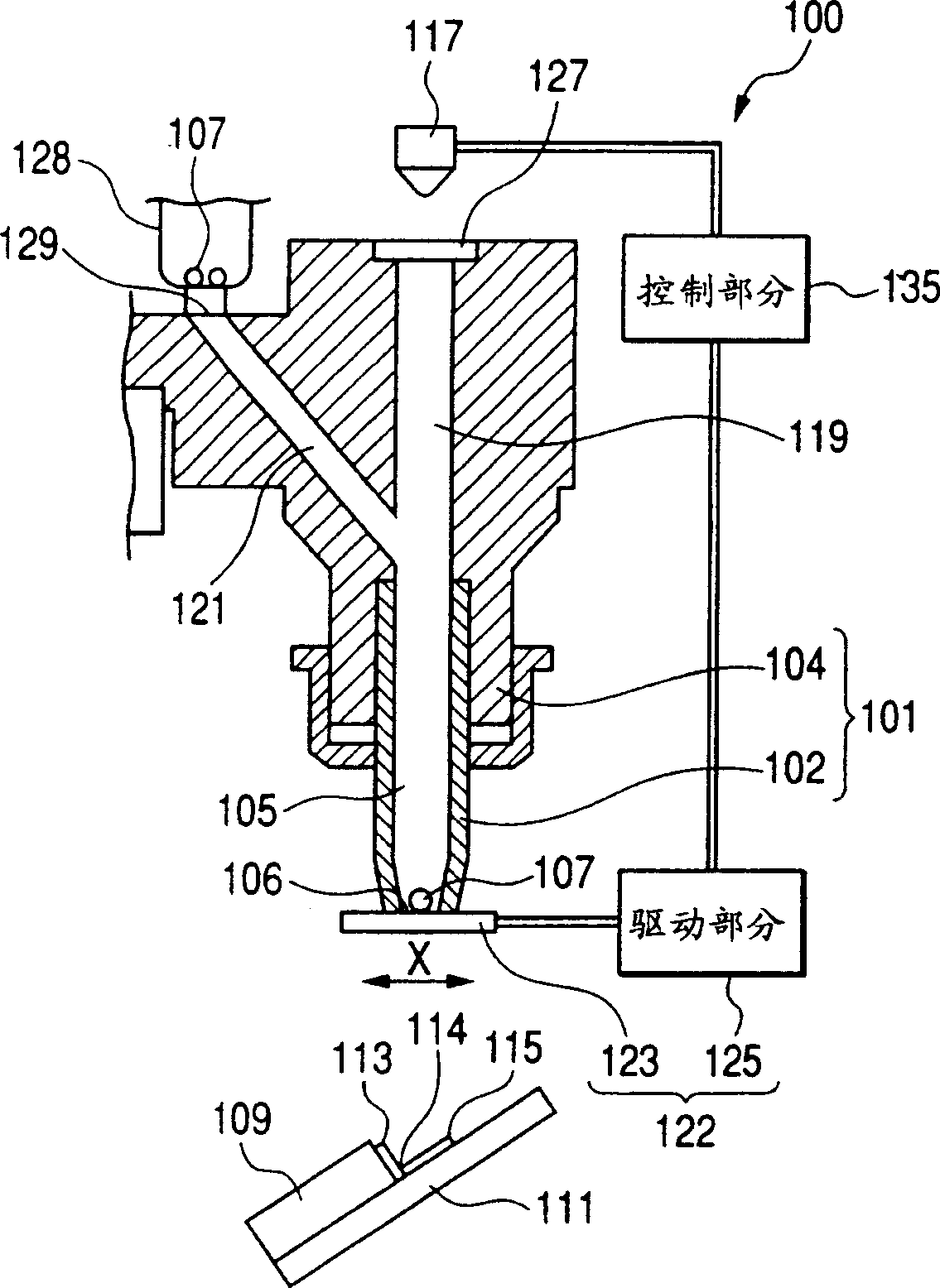

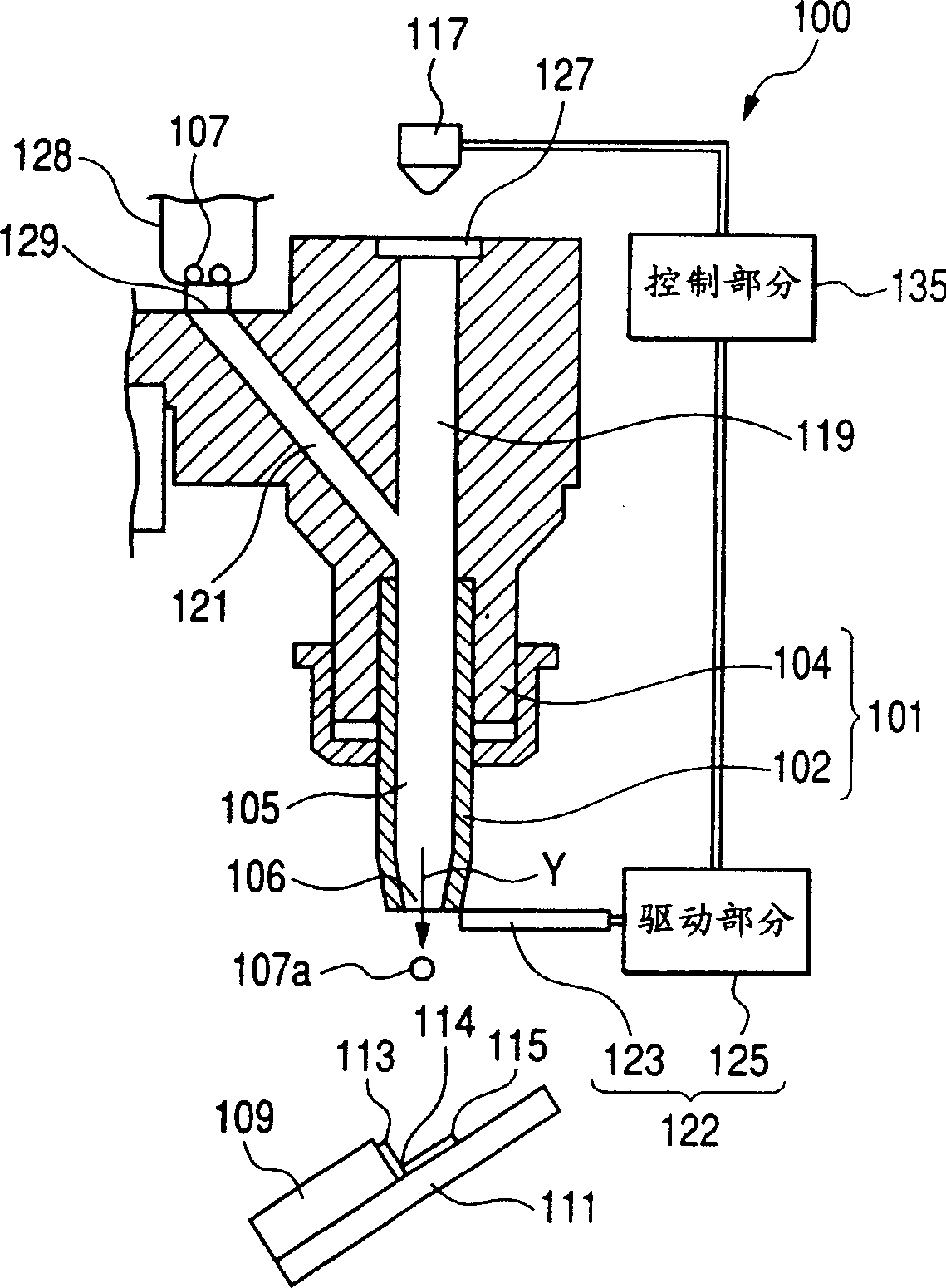

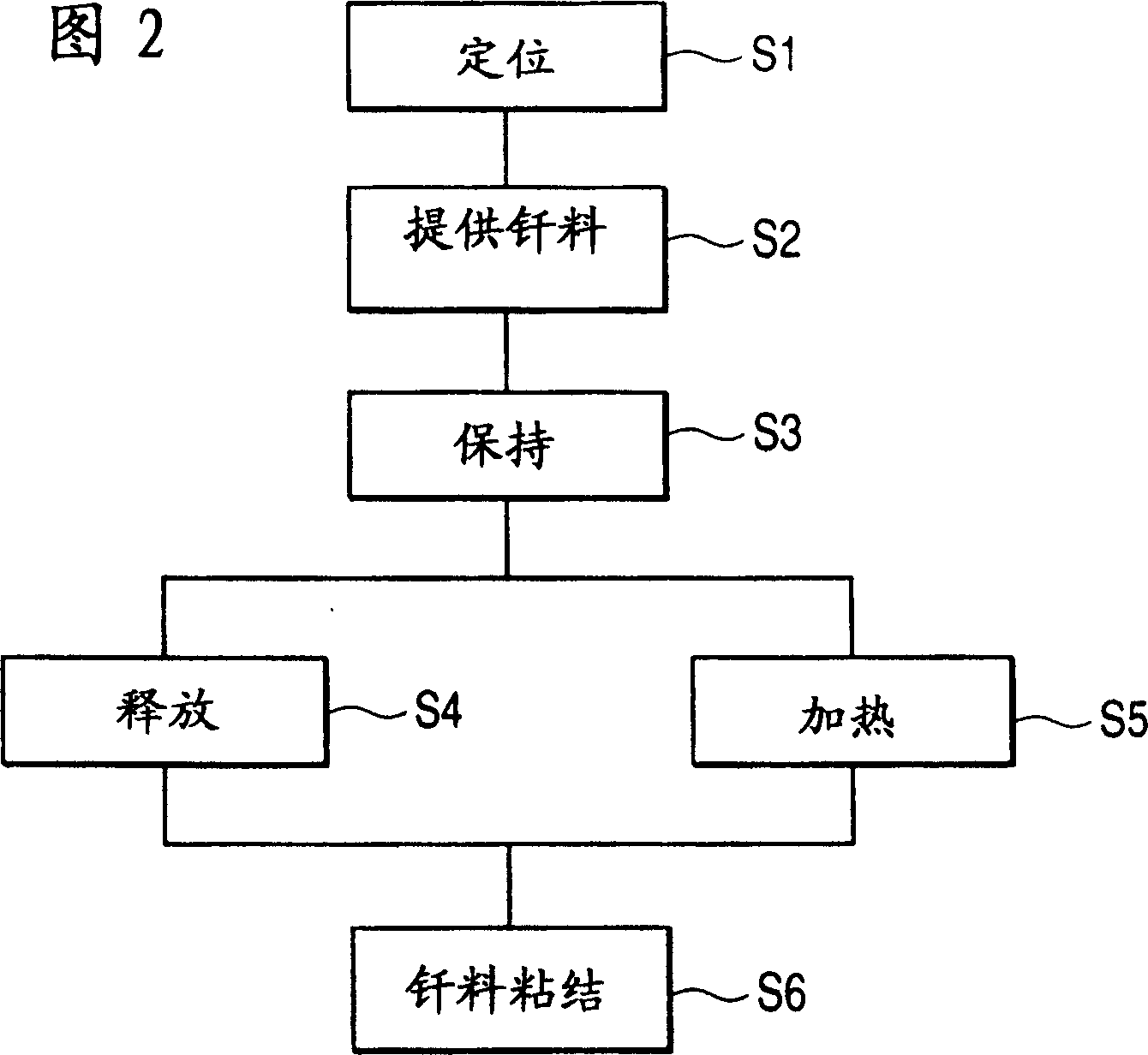

[0033] Figure 1A with 1B is a partial cross-sectional view of a brazing device according to an embodiment of the present invention; in Figure 1A With the shutter in the closed position, the device described in Figure 1B The midgate is in the open position. exist Figure 1A with 1B In the device of the illustrated embodiment, the electrical connection is made between a substantially rectangular head slider 109 to which a flexure 111 in the form of a thin plate will be attached by means of solder, or solder balls 107 .

[0034] First, the structure of the slider 109 and the bender 111 to be brazed will be explained. On the surface of one end portion of the slider 109, a slider electrode 113 formed of a metal plate is provided. A bender electrode 115 formed of a metal plate is provided on the bender 111, and the slider electrode 113 and the bender electrode 115 form a corner portion 114 at an angle of about 90 degrees. The molten solder ball 107a is adhered to a positi...

Embodiment 2

[0053] Although the opening / closing portion 122 is employed in the above-described Embodiment 1, holding and releasing of the solder balls can also be achieved by employing a suction device. Next, Embodiment 2 using a suction device will be described.

[0054] Fig. 3 is a sectional view of a part of a brazing apparatus having a suction device. Except for the components shown in FIG. 3 , the (other) components of the brazing apparatus of this embodiment are the same as those of the brazing apparatus in FIG. 1 , since FIG. 3 does not show components common to these embodiments. The nozzle 152 has a suction hole 187 near the opening 156 . The suction hole 187 extends horizontally through the wall of the nozzle 152 (as shown in FIG. 3 ), and communicates with the receiving portion 155 . In addition, one end of the suction pipe 174 is connected to the suction hole 187 . A suction device, that is, a suction device 175 generating a suction force is communicated to the other end of...

Embodiment 3

[0061] Next, a soldering apparatus according to Embodiment 3 of the present invention in which compressed gas is applied to the solder to spray the solder will be explained. Fig. 4 is a partial sectional view of a brazing apparatus according to Embodiment 3 of the present invention.

[0062] The slider 1151 and the bender 1155 to be brazed to each other are arranged such that the slider electrode 1153 and the bender electrode 1157 are at an elevation angle of substantially 90 degrees. There are at least four slider electrodes and four flexure electrodes. Temporary positioning of the slider 1151 and the bender 1155 is achieved by cement or a clamping mechanism, and the slider electrode 1151 and the bender 1155 form a groove 1159 at an elevation angle of approximately 90 degrees. The brazing nozzle 1102 is positioned so that the nozzle substantially corresponds to the center position of the groove 1159 in the width direction (the direction perpendicular to the plane of FIG. 4 )...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com