Swash plate compressor

A swash plate and compressor technology, which is applied to liquid variable capacity machinery, mechanical equipment, engine components, etc., can solve problems such as affecting the sliding part of the compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

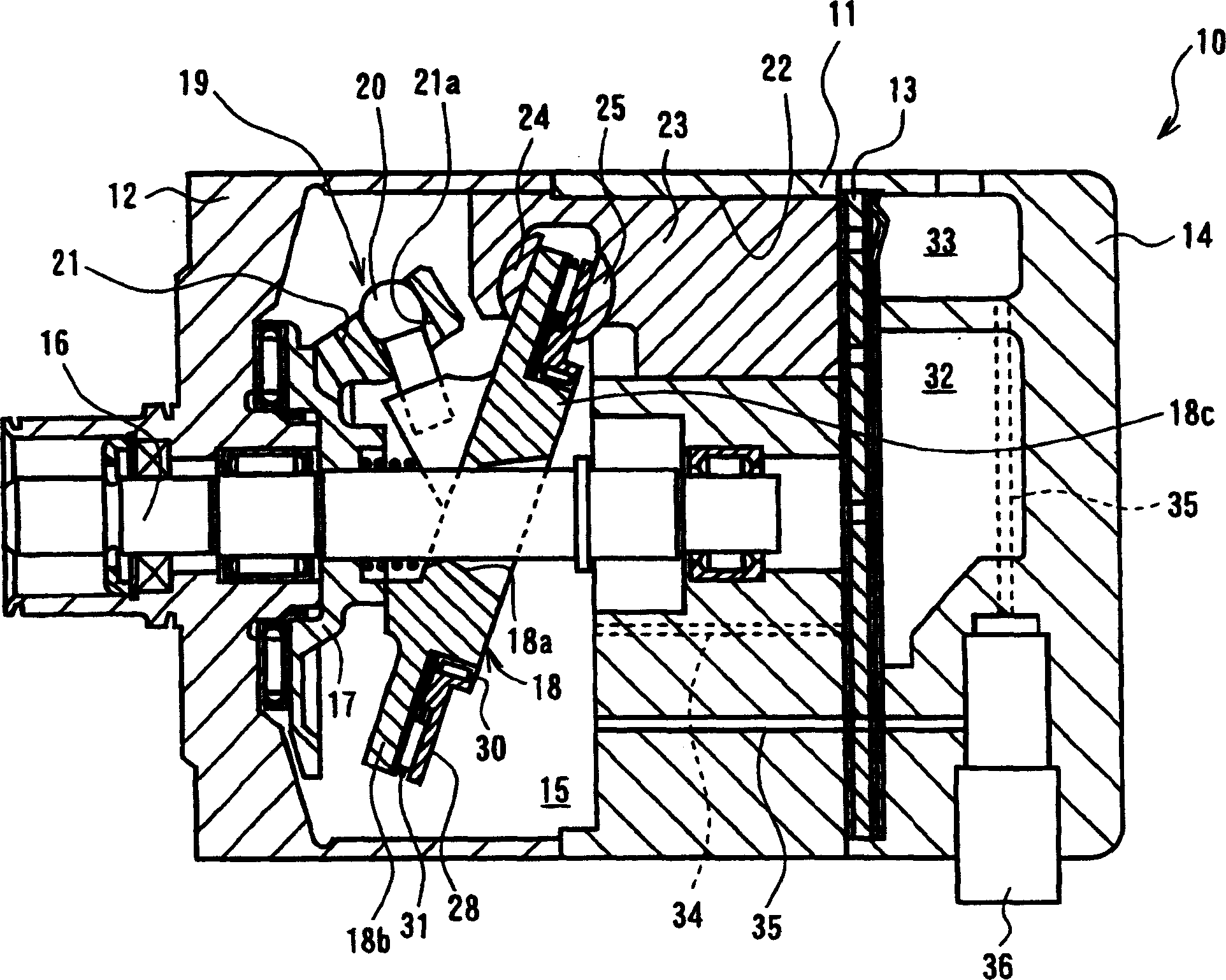

[0021] Refer below figure 1 and 2 A first preferred embodiment of the swash plate compressor according to the present invention will be described. figure 1 A longitudinal sectional view of a single-head piston type variable displacement swash plate compressor 10 is shown. figure 1 The left and right sides of the compressor 10 shown in FIG. 10 correspond to the front and rear sides of the compressor, respectively.

[0022] Such as figure 1 As shown, the compressor 10 includes a cylinder block 11 , a front casing 12 fixedly connected to the front end of the cylinder block 11 , and a rear casing 14 fixedly connected to the rear end of the cylinder block 11 through a valve plate assembly 13 . The cylinder block 11 , the front housing 12 and the rear housing 14 together form a housing assembly of the compressor 10 .

[0023] A crankcase 15 is formed between the cylinder block 11 and the front housing 12 in the housing assembly. A drive shaft 16 is rotatably supported at the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com