Conveying apparatus and method for liquid crystal display glass raw materials

A technology for liquid crystal display and glass raw material, which is applied to the conveying device and the field of conveying glass raw material for liquid crystal display, and achieves the effects of good wear resistance, improved overall uniformity, and avoidance of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

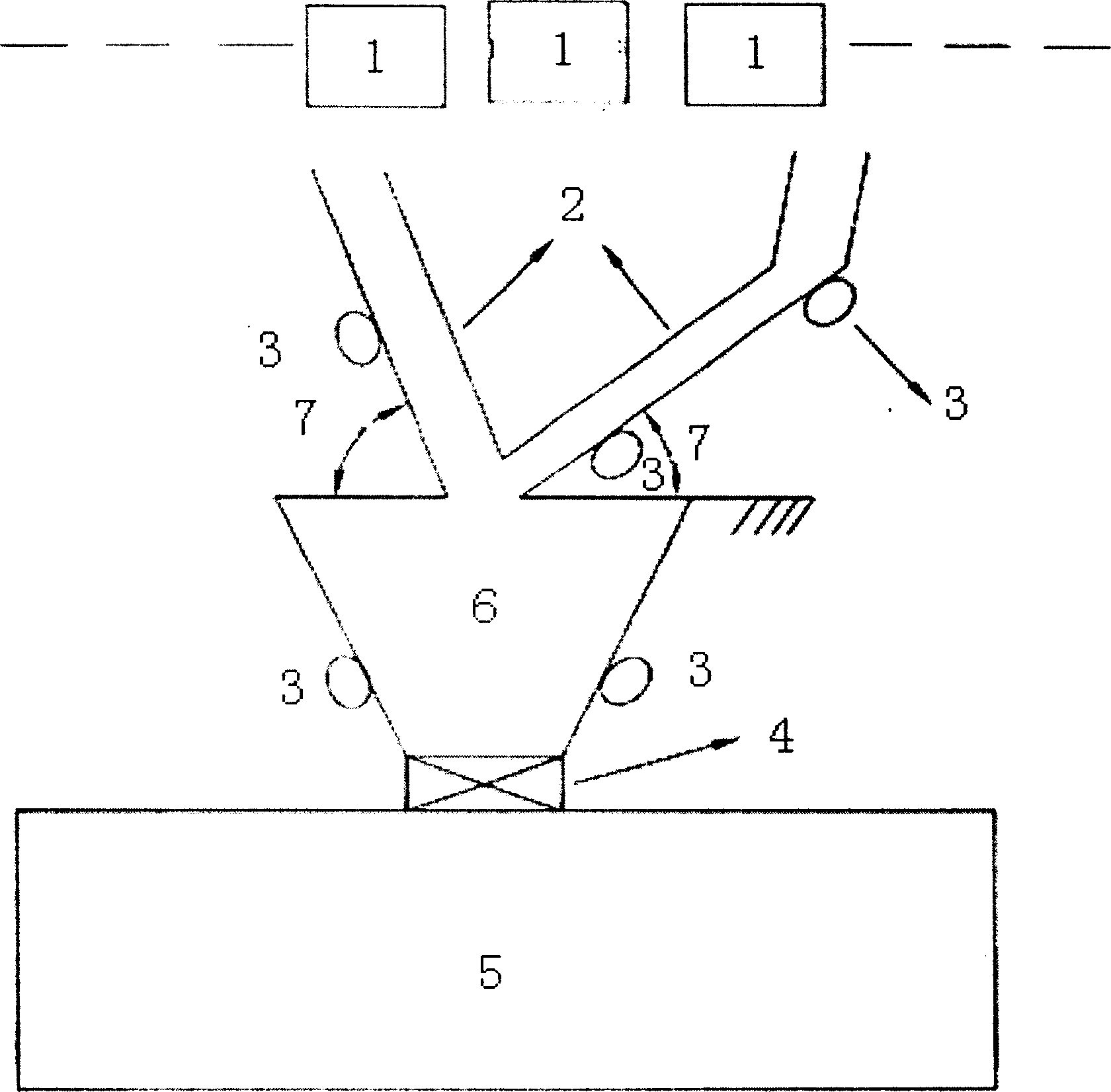

[0026] Such as figure 1 As shown, the present invention includes an electronic scale 1, the electronic scale 1 is connected to the collecting hopper 6 through the wear-resistant pipeline 2, and a discharge gate 4 and a vibration device 3 are arranged at the lower connection of the collecting hopper 6, and the collecting hopper 6 passes through The discharge gate 4 is connected with the mixer 5 .

[0027] The electronic scale 1 selects an electronic scale 1 with high precision, and discharges materials into the collecting hopper 6 through the discharge gate.

[0028] The wear-resistant pipeline 2 refers to a wear-resistant pipeline whose inner wall is lined with a layer of glass material.

[0029] The minimum included angle 7 between the wear-resistant pipeline 2 for transporting raw materials of each electronic scale 1 and the horizontal plane is greater than 40 degrees, and the outer wall of the wear-resistant pipeline 2 is equipped with a rapping device 3 .

[0030] A meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com