Generalized cycloidal active-tooth transmission

A technology of movable tooth transmission and cycloid, which is applied in the direction of gear transmission, transmission device, belt/chain/gear, etc., can solve the problem that the development and production of movable tooth transmission cannot be smoothly applied, it is not conducive to improving the dynamic performance of the device, and it has not been obtained in the industry To achieve the effect of improving manufacturability and transmission performance, excellent dynamic performance and reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

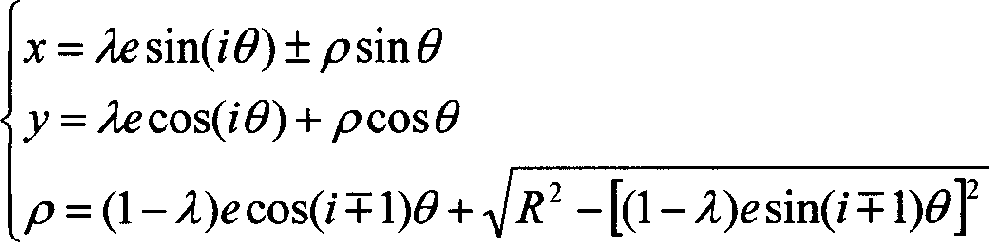

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

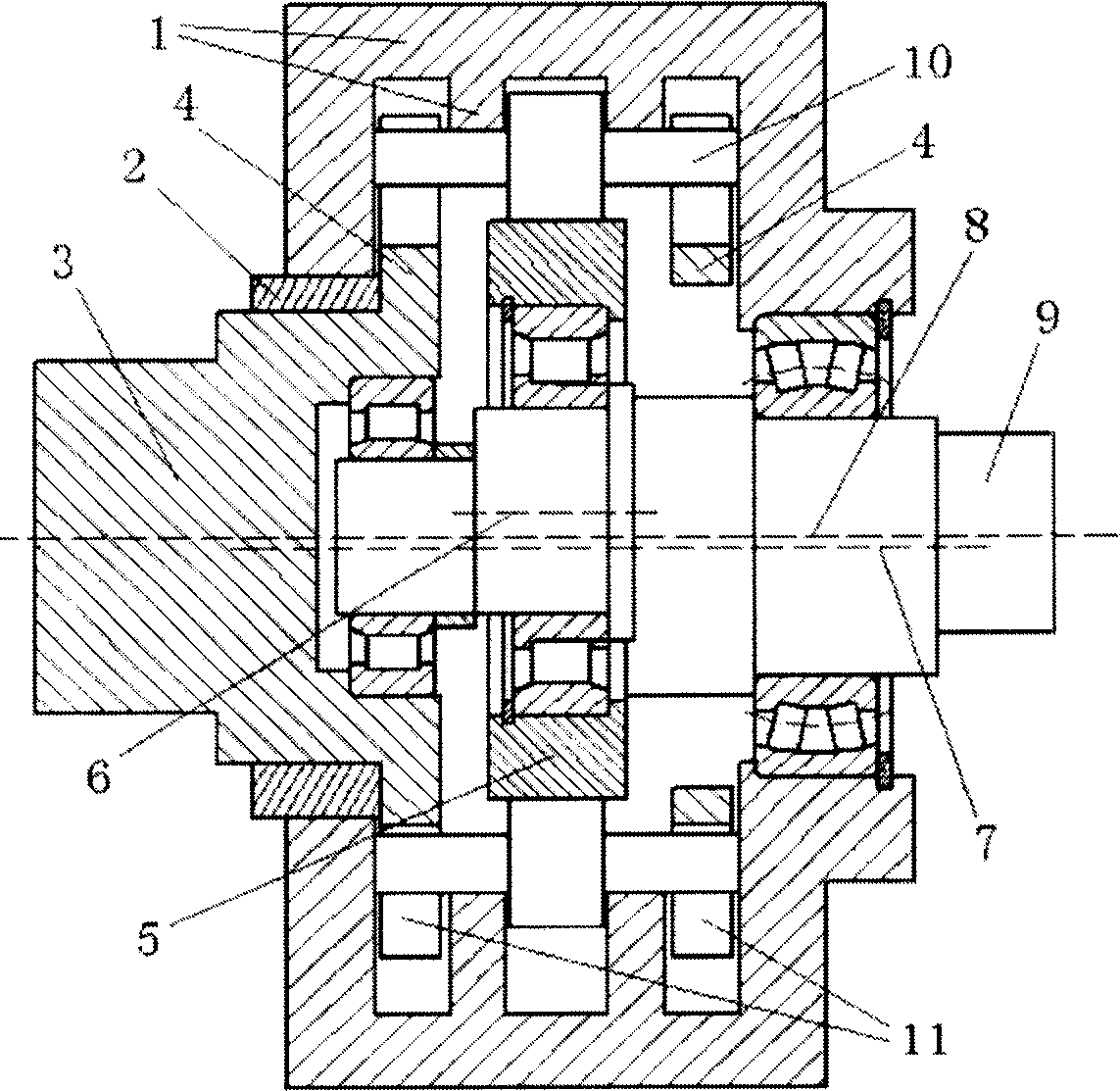

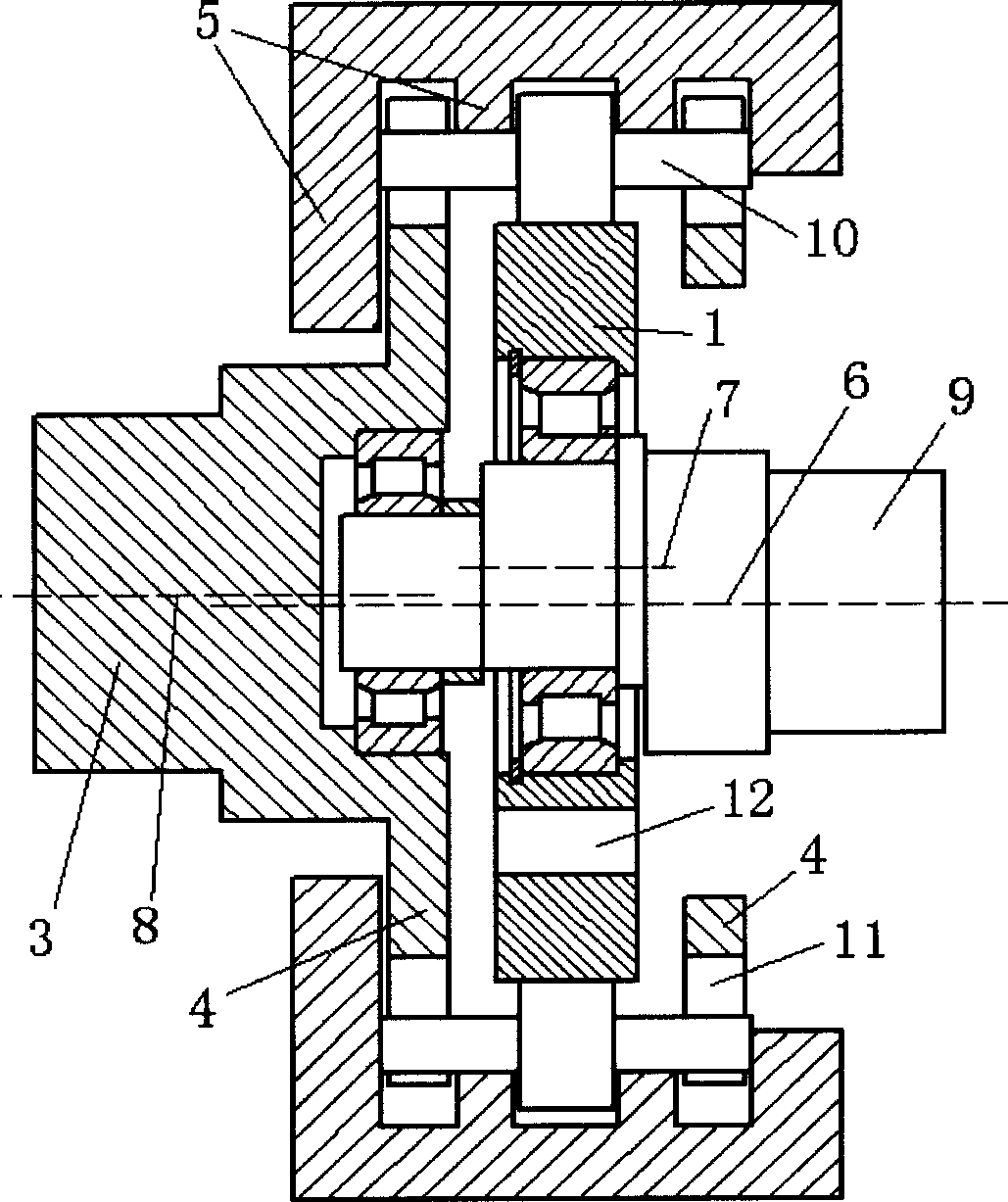

[0028] figure 1 , figure 2 The shapes and names of all the parts are based on the chapter "Moving tooth transmission" in Volume 3 of the fourth edition of "Machine Design Handbook" published by Chemical Industry Press and refer to the traditional national standard of cycloidal pinwheel transmission . It is particularly supplemented that, due to the eccentricity of the transmission parts in pairs, a fixed gear pin hole 12 for the installation of the W mechanism is added on the fixed gear.

[0029] Such as figure 1 As shown, for the convenience of description, it is assumed that the input shaft 9, the output shaft 3, and the rotation axis 8 of the force transmission plate (movable tooth revolution axis) are coaxial (the actual design can be handled flexibly), and the input shaft 9 and the output shaft 3 are installed on the base.

[0030] Obviously, figure 1 The ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com