Compression refrigeration and solution combined gas dehumidifying system

A compression refrigeration and solution technology, used in air conditioning systems, heating methods, lighting and heating equipment, etc., can solve problems such as low efficiency, increased refrigeration power consumption, and discomfort in indoor hot and humid environments, and achieve harm prevention and dehumidification effects. Good, simple and flexible system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

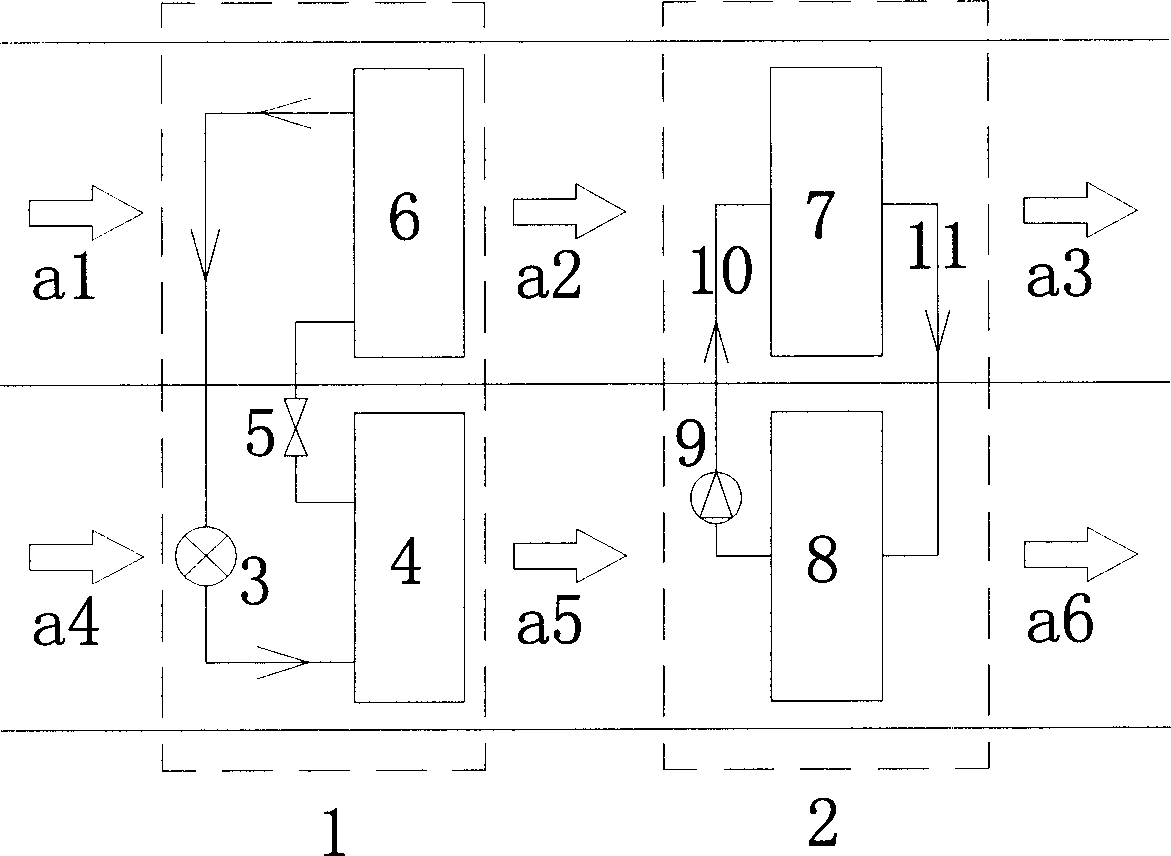

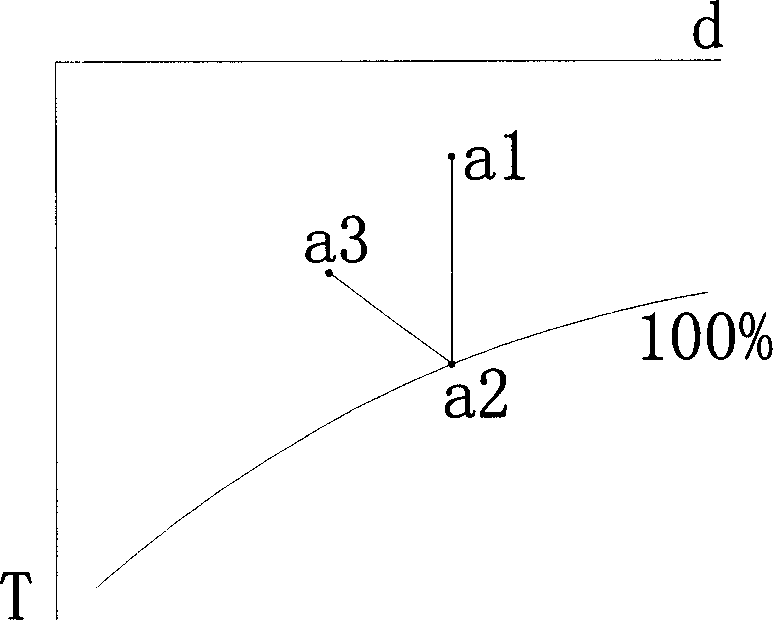

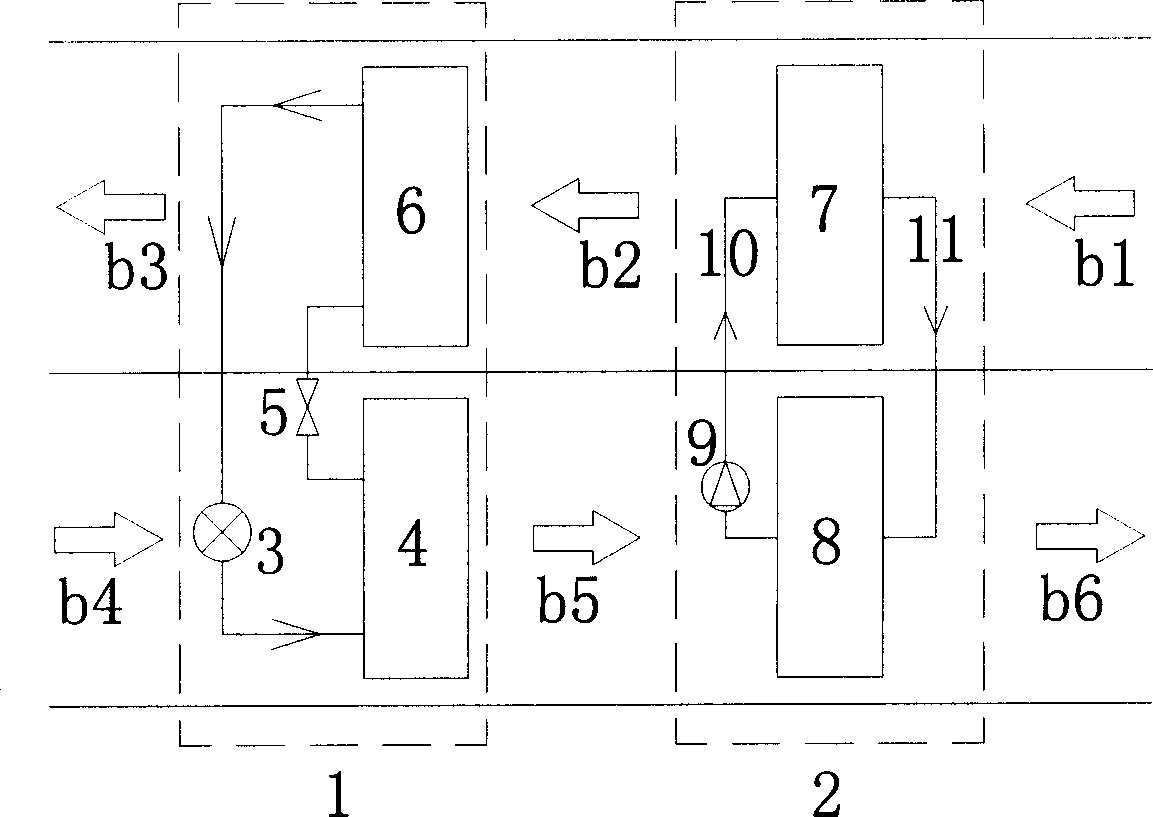

[0025] Such as figure 1 As shown, 1 is the compression refrigeration system, 2 is the solution system, 3 is the compressor, 4 is the condenser, 5 is the throttle valve, 6 is the evaporator, 7 is the dehumidifier of the solution system, and 8 is the regeneration of the solution system 9 is a pump, a1 is the dehumidified gas, a2 is the gas after the gas a1 passes through the evaporator of the compression refrigeration system, a3 is the gas after the gas a2 passes through the dehumidifier of the solution system, a4 is the regeneration gas, and a5 is Gas a4 is the gas after passing through the condenser of the compression refrigeration system, and a6 is the gas after gas a5 passes through the regenerator of the solution system. The concentrated solution 10 of the regenerator of the solution system is introduced into the dehumidifier of the solution system, and the dilute solution 11 of the dehumidifier of the solution system is introduced into the regenerator of the solution syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com