Super-high-speed high-power magnetic-suspension main-shaft motor

A spindle motor and high-power technology, applied in the direction of bearings, electromechanical devices, electrical components, etc., can solve the problems of occupying axial space, limiting the miniaturization critical speed and output power of high-speed spindle motors, and complex structures, so as to achieve the bearing capacity and Increased rigidity, easy modularization and machining, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

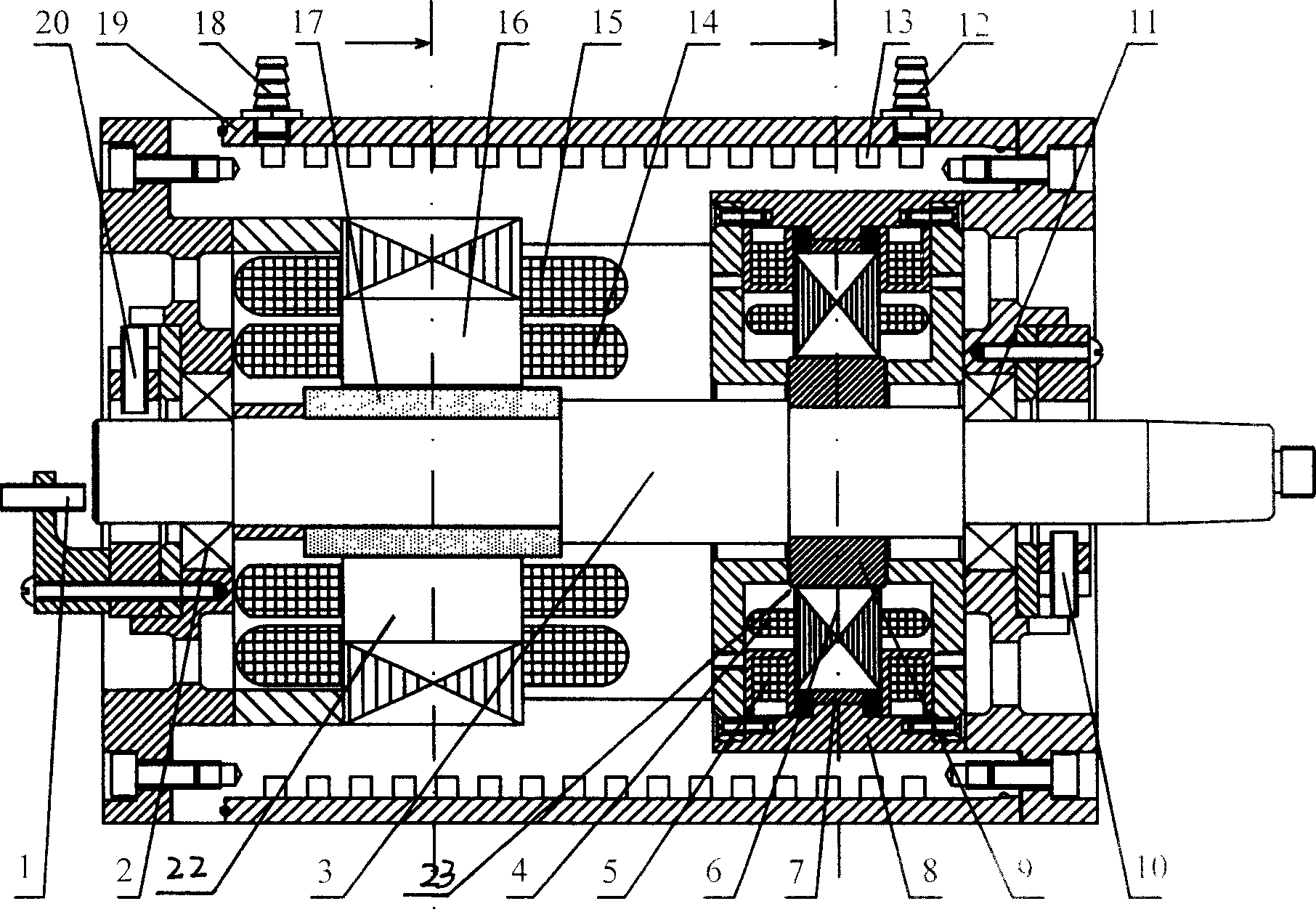

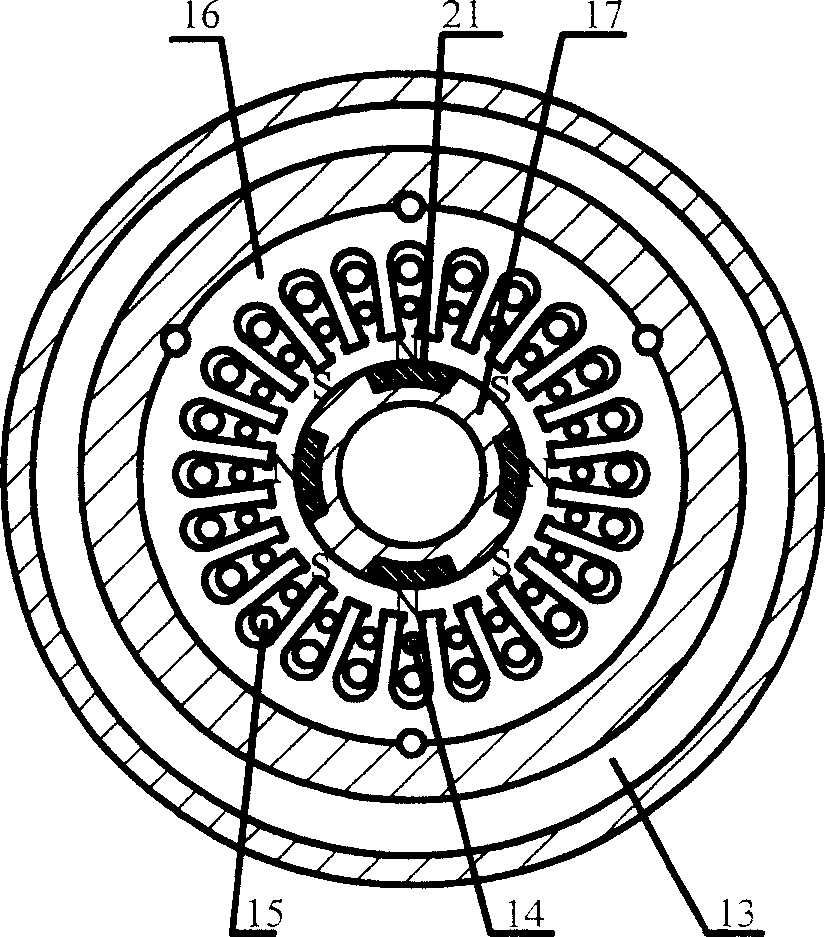

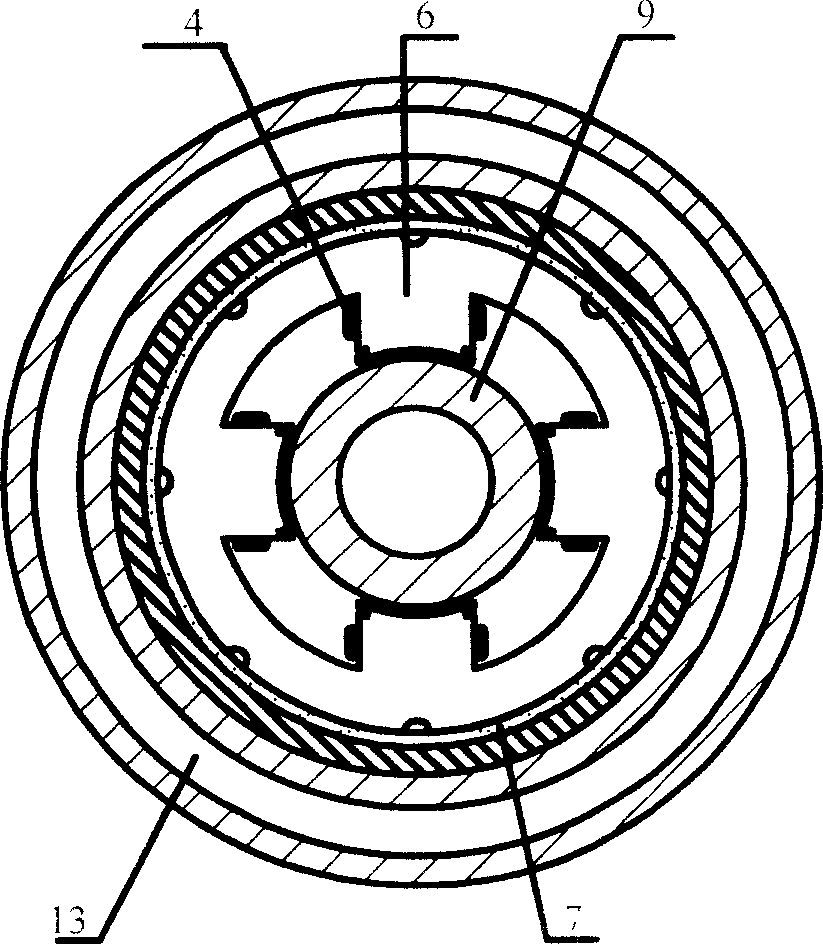

[0013] like figure 1 As shown, the ultra-high-speed and high-power magnetic levitation spindle motor of this embodiment includes a casing 19, a spindle 3, a bearingless alternating pole permanent magnet motor 22, a three-degree-of-freedom permanent magnet bias hybrid magnetic bearing 23 and auxiliary bearings 2, 11. The three-degree-of-freedom permanent magnet bias hybrid magnetic bearing 23 is installed on the main shaft 3 between the bearingless alternating pole permanent magnet motor 22 and the casing 19, and the auxiliary bearing 2 is installed on the side of the bearingless alternating pole permanent magnet motor 22 At the center position of the end cover, the auxiliary bearing 11 is installed at the center position of the end cover on one side of the three-degree-of-freedom permanent magnet bias hybrid magnetic bearing 23, wherein a stator slot 16 of the bearingless alternating pole permanent magnet motor 22 is respectively embedded in a A set of three-phase torque windi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com