Local-reinforced apron rubber and its production

A local reinforcement and manufacturing method technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve problems such as apron damage, water leakage, poor resistance of adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

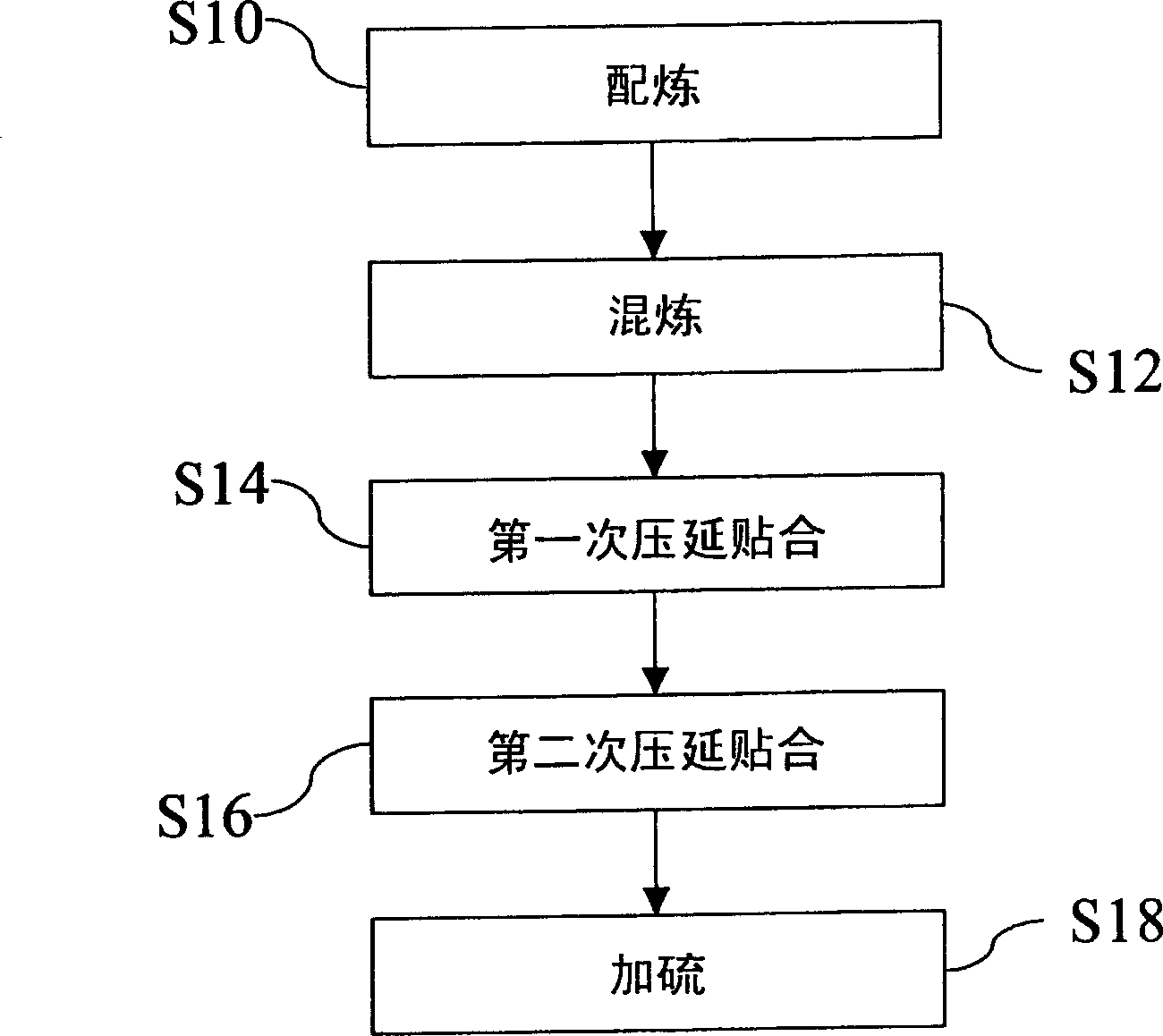

[0046] Example 1: General single-layer apron rubber

[0047] 100 parts by weight of polypropylene-butadiene rubber (PHR), internal and external lubricant 1.0PHR, calcium carbonate 40PHR, plasticizer 10.0PHR and other compositions are carried out in a 10,000-horsepower mixing device to mix uniformly; The compounded rubber is transported to the first rolling machine (setting temperature 70-80°C), and mixed with vulcanization accelerator 1.9PHR and bridging agent 1.8PHR; then the rubber is transported to the second Fully knead in two rolling mills (setting temperature 80-90°C); then send the uniformly mixed rubber to the calender to be rolled into the required thickness, and the temperature of the calender is set at 90-110°C; After the rubber material is calendered, the rubber flakes are drawn out with polyester-nylon blended gauze (fabric) as the carrier. The thickness of the rubber flakes is set at 0.38mm and the width is 54 inches; Sulfur, the temperature is set at 130-150°C ...

example 2

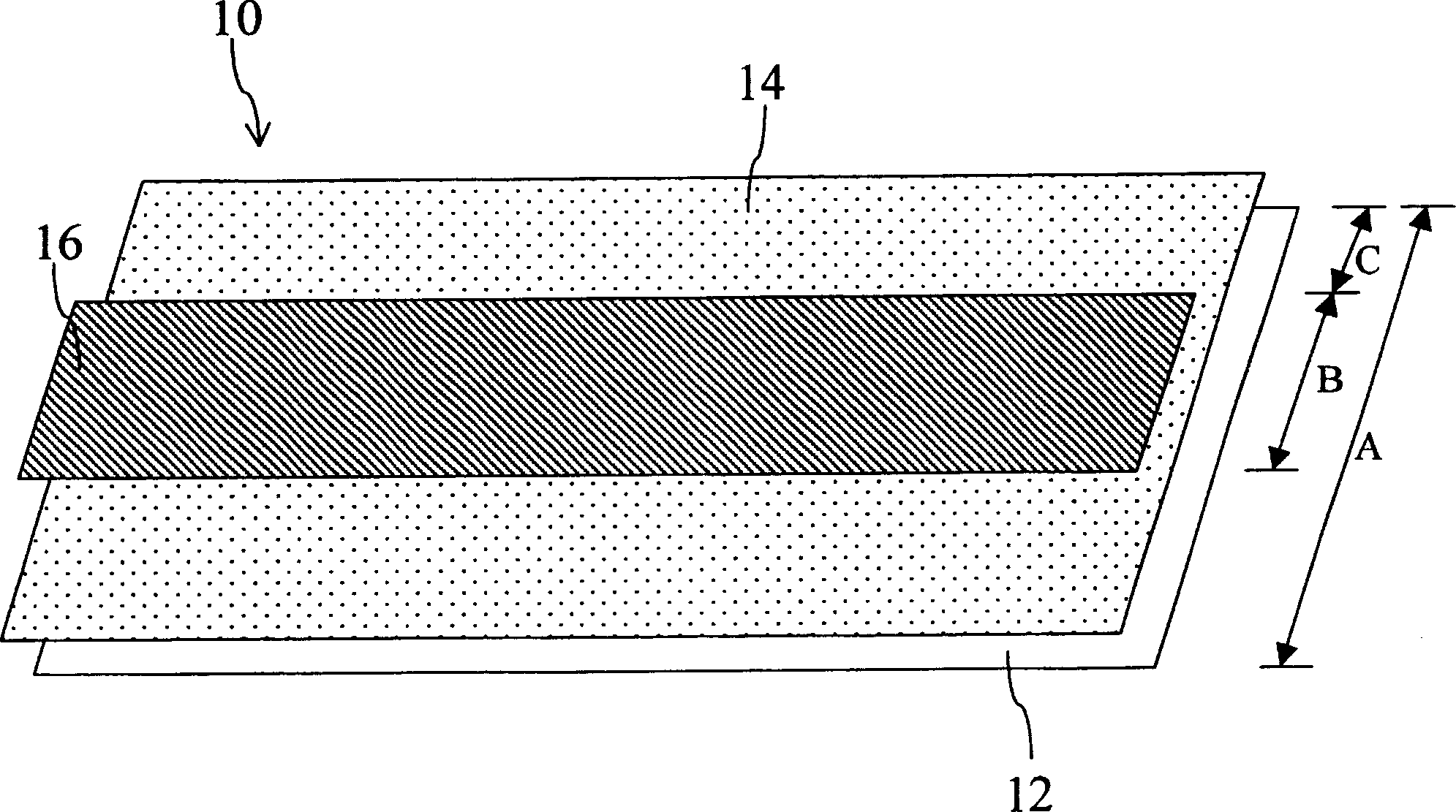

[0050] Example 2: Abdominal reinforcement apron rubber

[0051] Using the same rubber compound as in Example 1, carry out the second calendering process before adding vulcanization. During the first calendering, the thickness of the rubber sheet is set at 0.38 mm and the width is 54 inches. After the rubber sheet is wound up, Then carry out the second calendering procedure, the thickness of the rubber sheet (reinforcing rubber) is set at 0.20mm, and the width of the glue is 14in; then all the rubber sheets are sent to the vulcanizing device for vulcanization, and the temperature is set at 130~ 150°C 2 , and the time is 15 minutes. After the vulcanization is completed, the rubber apron rubber for abdominal reinforcement can be obtained.

[0052] The abdomen reinforcing apron rubber that is made above is carried out physical property test, and its test result is shown in Table 2.

[0053] head

unit

result

Detection method

thickness

mm

0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com