Wide temperature rang, low temperature coefficient, high magnetic permeability NiZn ferrite material and its preparing method

A technology of ferrite material and low temperature coefficient, which is applied in the field of NiZn ferrite material and its preparation, can solve the problems of reducing pre-sintering and sintering temperature, large energy consumption, and increasing steel ball loss, etc., to achieve lower sintering temperature, Effect of low temperature coefficient and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

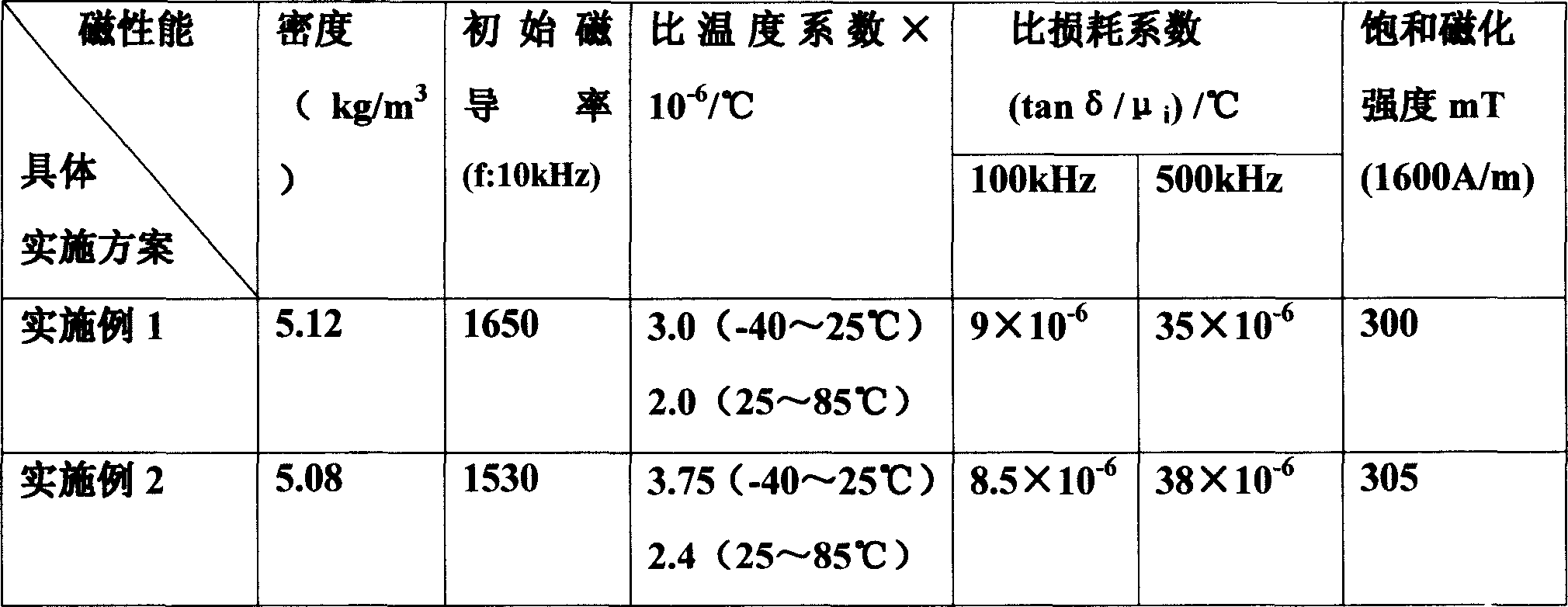

Embodiment 1

[0036] 1. the selection of raw material: the raw material of the Ni-Zn ferrite material of the low-temperature sintering provided by the invention selects industrial pure Fe 2 o 3 , ZnO, NiO and CuO.

[0037] 2. Composition design and weighing: Weigh 49mol% Fe according to molar percentage 2 o 3 , 31 mol% ZnO, 9 mol% NiO and 11 mol% CuO.

[0038] 3. Mixing of raw materials: Put the weighed raw materials into a ball mill, add an equal weight of deionized water, and ball mill for 7 hours, so that the average particle size of the raw materials is 1.0 μm.

[0039] 4. Pre-burning: Dry the mixed and ground raw materials and put them into the furnace for pre-burning. The pre-firing temperature is 750°C, the pre-firing time is 4 hours, the atmosphere is air, and it is cooled with the furnace after pre-firing.

[0040] 5. Secondary ball milling: add the auxiliary component Cr into the calcined material 2 o 3 0.2 wt%, MoO 3 0.05% by weight of equal weight of deionized water was ...

Embodiment 2

[0044] 1. the selection of raw material: the raw material of the Ni-Zn ferrite material of the low-temperature sintering provided by the invention selects industrial pure Fe 2 o 3 , ZnO, NiO and CuO.

[0045] 2. Composition design and weighing: Weigh 49mol% Fe according to molar percentage 2 o 3 , 30mol% ZnO, 11mol% NiO and 10mol% CuO.

[0046] 3. Mixing of raw materials: Put the weighed raw materials into a ball mill, add an equal weight of deionized water, and ball mill for 6 hours, so that the average particle size of the raw materials is 1.2 μm.

[0047] 4. Pre-burning: Dry the mixed and ground raw materials and put them into the furnace for pre-burning. The pre-firing temperature is 790°C, the pre-firing time is 2 hours, the atmosphere is air, and it is cooled with the furnace after pre-firing.

[0048] 5. Secondary ball milling: add the auxiliary component Cr into the calcined material 2 o 3 0.1wt%, MoO 3 0.03wt%, WO 3 0.04wt% deionized water of equal weight was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com