Filling method for unwanted holes in clouds of three dimension scanning

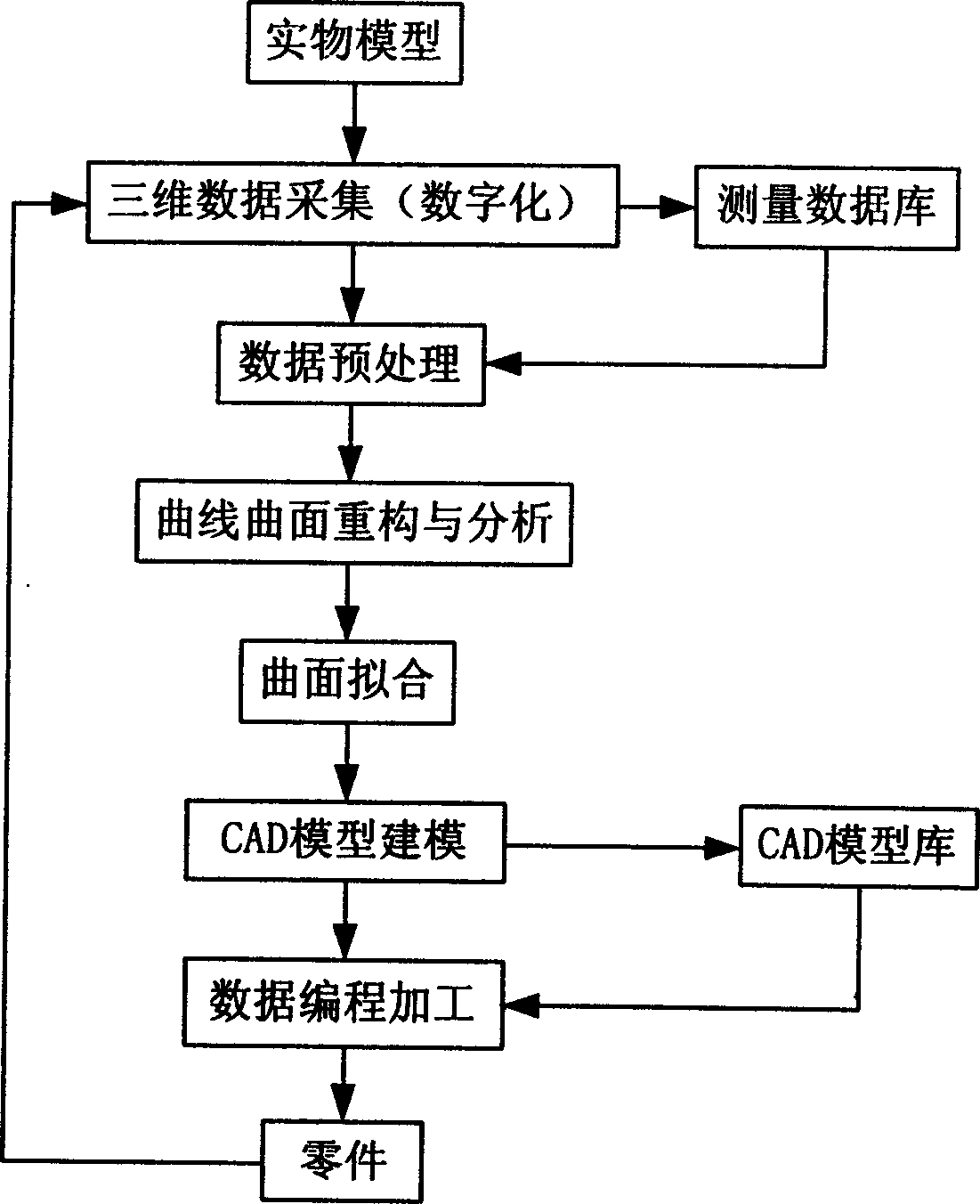

A point cloud and hole technology, which is applied in the field of point cloud hole filling in 3D scanning, can solve the problems of low efficiency, large amount of calculation, and poor approximation effect of discrete points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

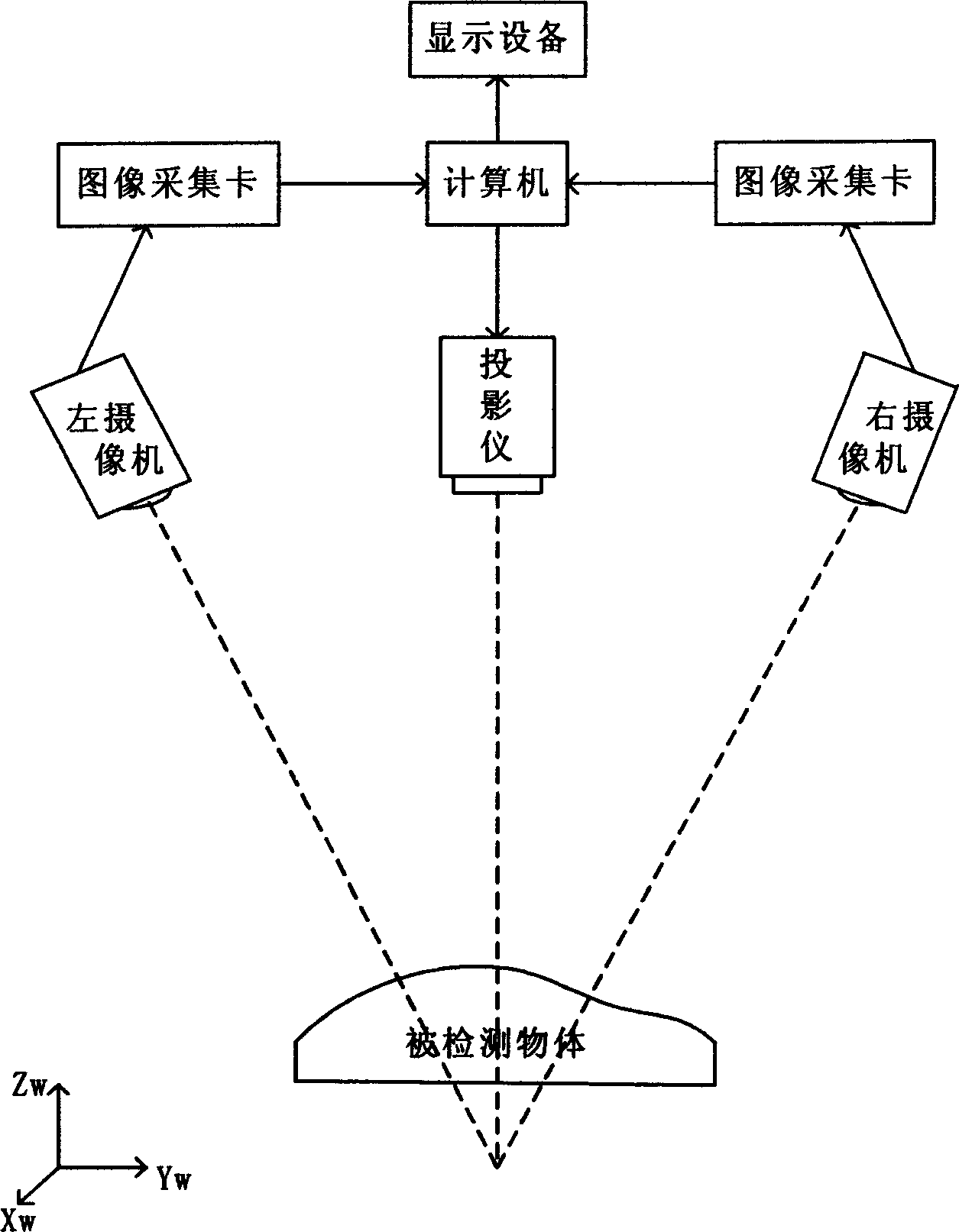

Method used

Image

Examples

Embodiment Construction

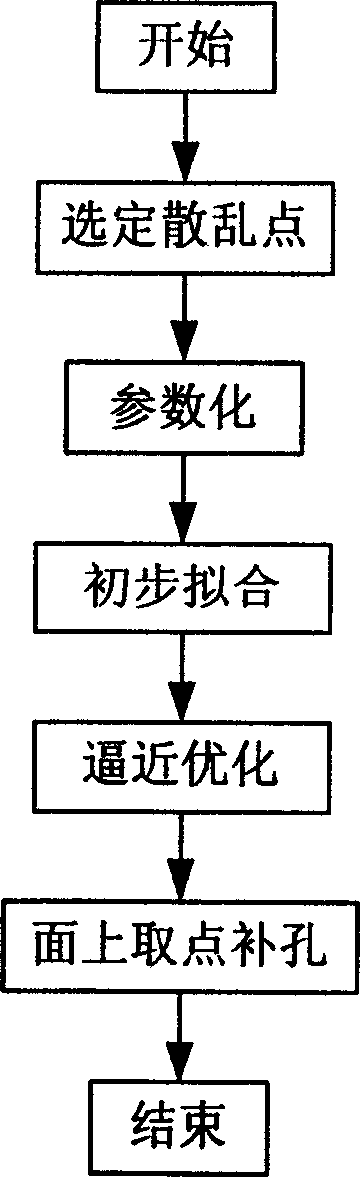

[0044] A point cloud hole filling method based on 3D scanning of triangular Bezier surfaces:

[0045] Step 1: Set a triangle ABC around the point cloud hole and in the screen coordinate plane. The area of the triangle ABC can make the projection of the point cloud hole and its surrounding points to the screen coordinate plane fall into the triangle ABC, and The point that the projection falls into the triangle ABC is used as the point P of the fitting surface when filling the hole s (s=0,1,...,m-1), according to the point P of the fitting surface s Projection P on the plane ABC of the triangle s ’ position to calculate its surface parameterized coordinates (u s , v s ,w s ), u s =(ΔAP s 'B area) / (ΔABC area), v s =(ΔAP s 'C area) / (ΔABC area), w s =(ΔBP s 'C area) / (ΔABC area), will fit the point P of the surface s (s=0,1,...,m-1) coordinates and its surface parameterized coordinates (u s , v s ,w s ) into the Bezier surface equation of degree n and the control po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com