Heavy load door and its producing method

A manufacturing method and heavy-duty technology, which is applied in the direction of sealed shells, casings/cabinets/drawer parts, etc., can solve problems such as sealing failures, and achieve the effects of improved sealing, enhanced rigidity, and small welding volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below we will describe in detail the best implementation of the present invention with reference to the accompanying drawings. First of all, it should be pointed out that the meanings of the terms, words and claims used in the present invention should not be limited to their literal and ordinary meanings, but also include meanings and concepts that are consistent with the technology of the present invention. This is because It is up to us, as inventors, to define terms appropriately in order to best describe our inventions. Therefore, the configurations given in this specification and the accompanying drawings are only preferred implementations of the present invention, rather than enumerating all technical characteristics of the present invention. We need to recognize that there are various equivalents or modifications that could replace ours.

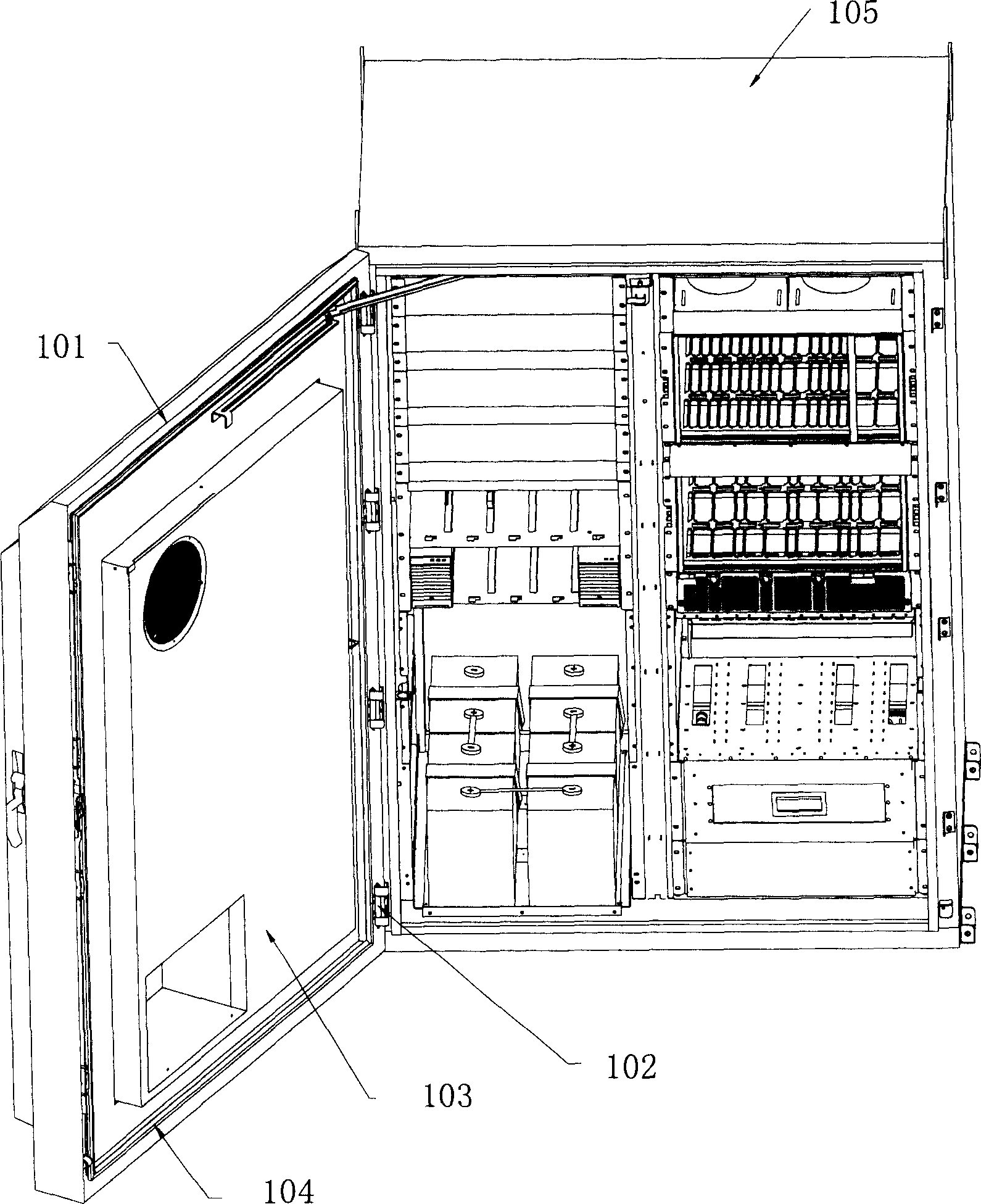

[0031] Figure 4 It is a structural diagram of a preferred embodiment of the heavy-duty door of the present invention. As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com