Belljar type grid distribution device for ceramic forming press and its distribution method using the distribution device

A material distribution device and forming machine technology, which is applied to ceramic forming machines, forming pressure heads, forming conveyors, etc., can solve problems such as difficult promotion and short service life, and achieve good decoration effects, fast decoration speed, and significant economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

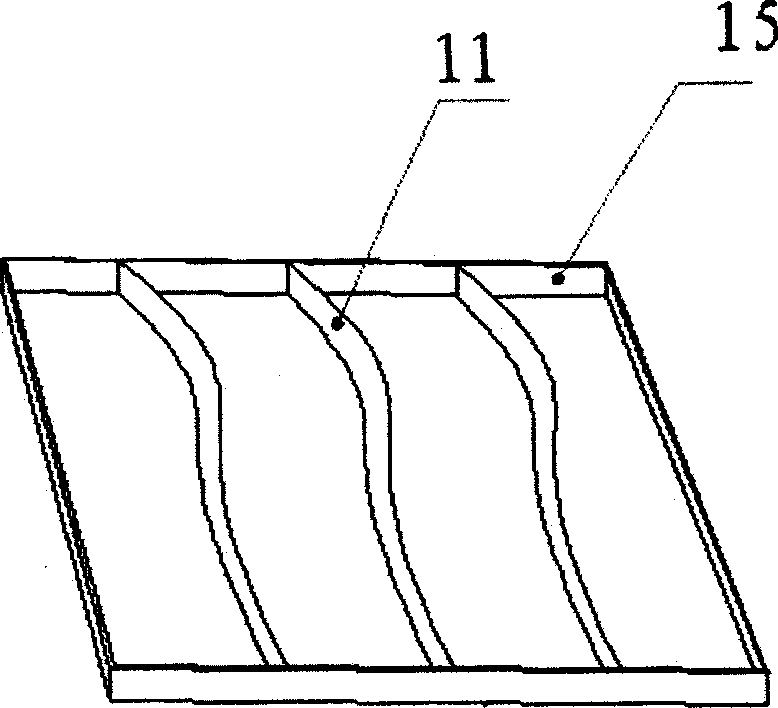

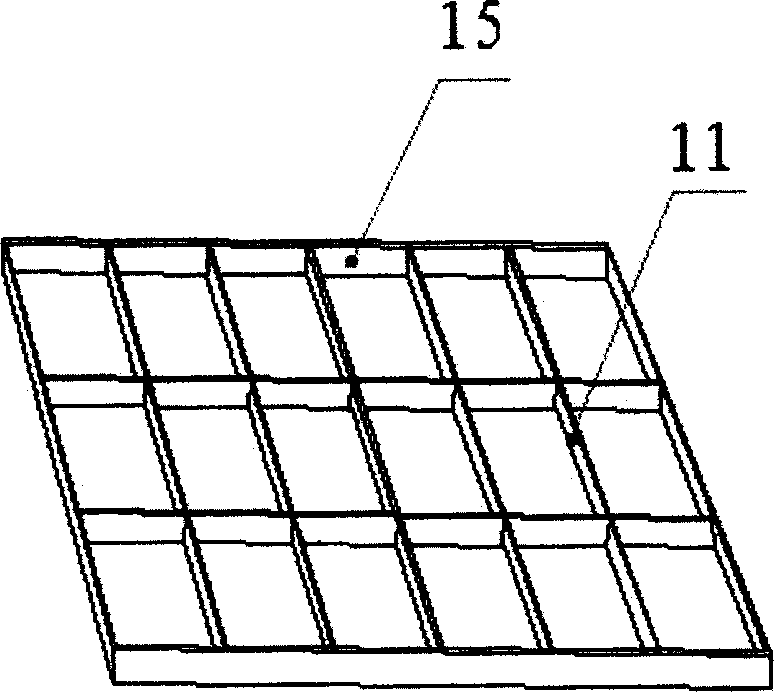

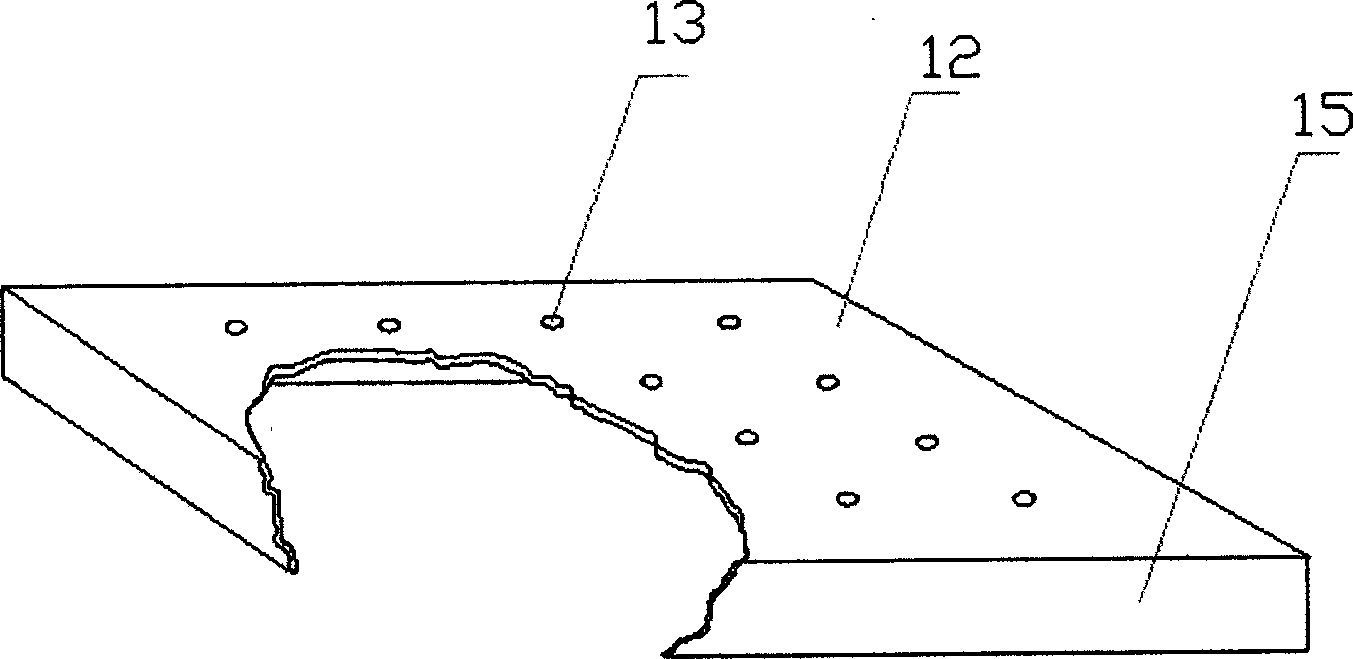

[0050] Such as Figure 5-1 , Figure 5-2 , Figure 5-3 , Figure 5-4 , Figure 6-1 , Figure 6-2 , Figure 6-3 As shown, a bell-type grid distribution device of a ceramic molding press of the present invention includes a press and a feeder, and a bell-type grid 3 is arranged between the press and the feeder, and the grid There is a discharge gate between 3 and the press. The bell-jar grid 3 is a hollow body surrounded by a fixed frame, and a cover plate 12 is connected to its upper surface. The lower surface of the cover plate 12 is provided with an elastic material layer (such as sponge, rubber, air bag, liquid bag, ball ball, spring, etc.). The lower surface of the elastic material layer can be provided with an elastic body 14 surface layer, which is used to isolate the powder from the elastic material layer. Vent holes 13 are provided in the cover plate 12 and the elastic material layer. The cross-section of the fixed frame of the grid 3 is a wedge shape with a lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com