Lower-pipe type permanent-magnet vortex heating device for oil well

A permanent magnet eddy current and heating device technology, which is applied in isolation devices, boreholes/well components, earthwork drilling and production, etc., can solve the problems of unsuitable oil well heating and difficulty in rotating motion, and achieve simple structure, high heat transfer efficiency, Good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

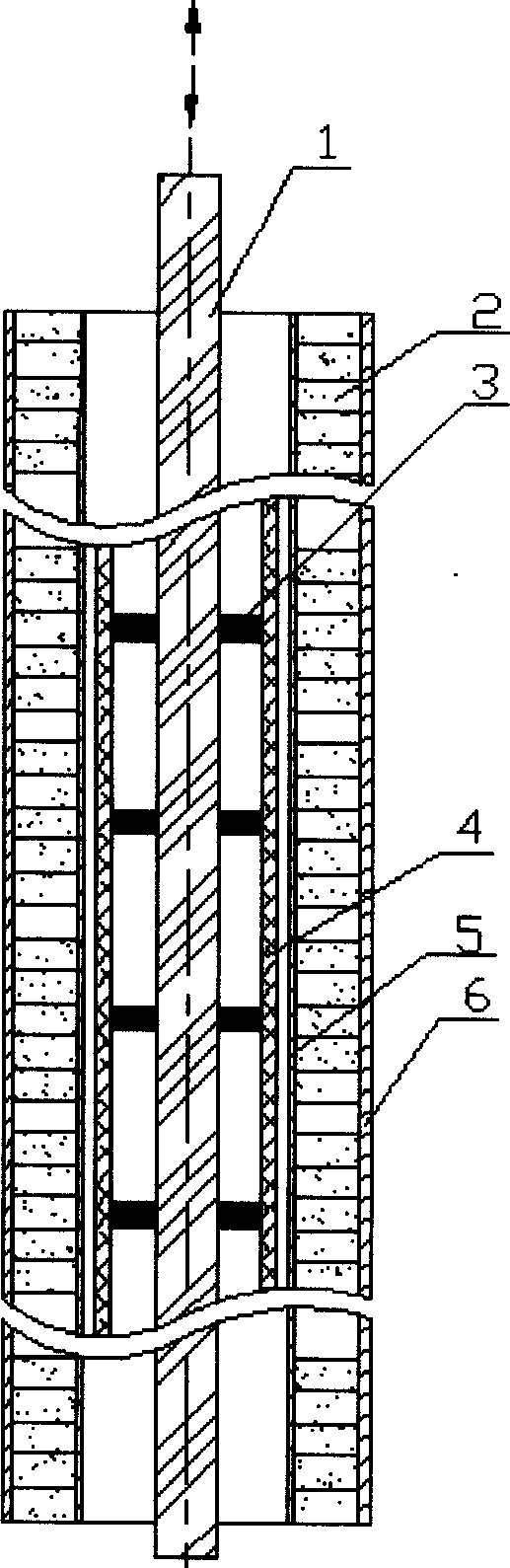

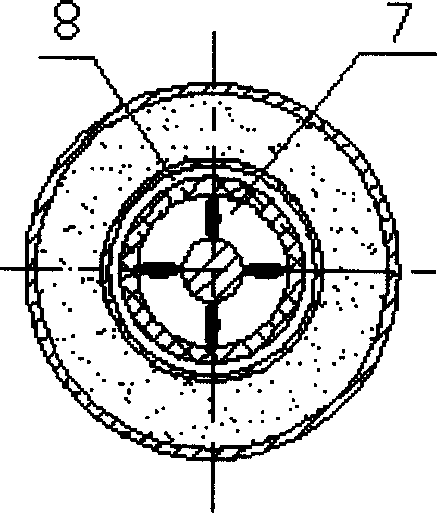

[0020] Fig. 2 is a schematic structural diagram of a specific embodiment of the present invention. As shown in Figure 2, the specific embodiment of the present invention consists of a sucker rod 1, an internal magnetic tubular permanent magnet 2, a bracket 3, an induction heating copper sleeve 4, a metal inner shell 5, a metal outer shell 6, and an internal flow passage 7 , Overcurrent outer channel 8 components. Wherein the sucker rod 1, the bracket 3, the induction heating copper sleeve 4, the overcurrent inner channel 7, and the overcurrent outer channel 8 are coaxially located in the magnetic hole of the inner magnetic tubular permanent magnet 2.

[0021] The sucker rod 1 is made of non-magnetic alloy steel with an outer diameter of 19 mm, and is arranged coaxially with the inner magnetic tubular permanent magnet 2 . The induction heating cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com