High-power laser diode array structure

A technology of laser diode and array structure, applied in lasers, laser devices, laser parts and other directions, can solve the problems of complex manufacturing process, low service life and high production cost, and achieve simple processing and assembly process, long service life, and production maintenance. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

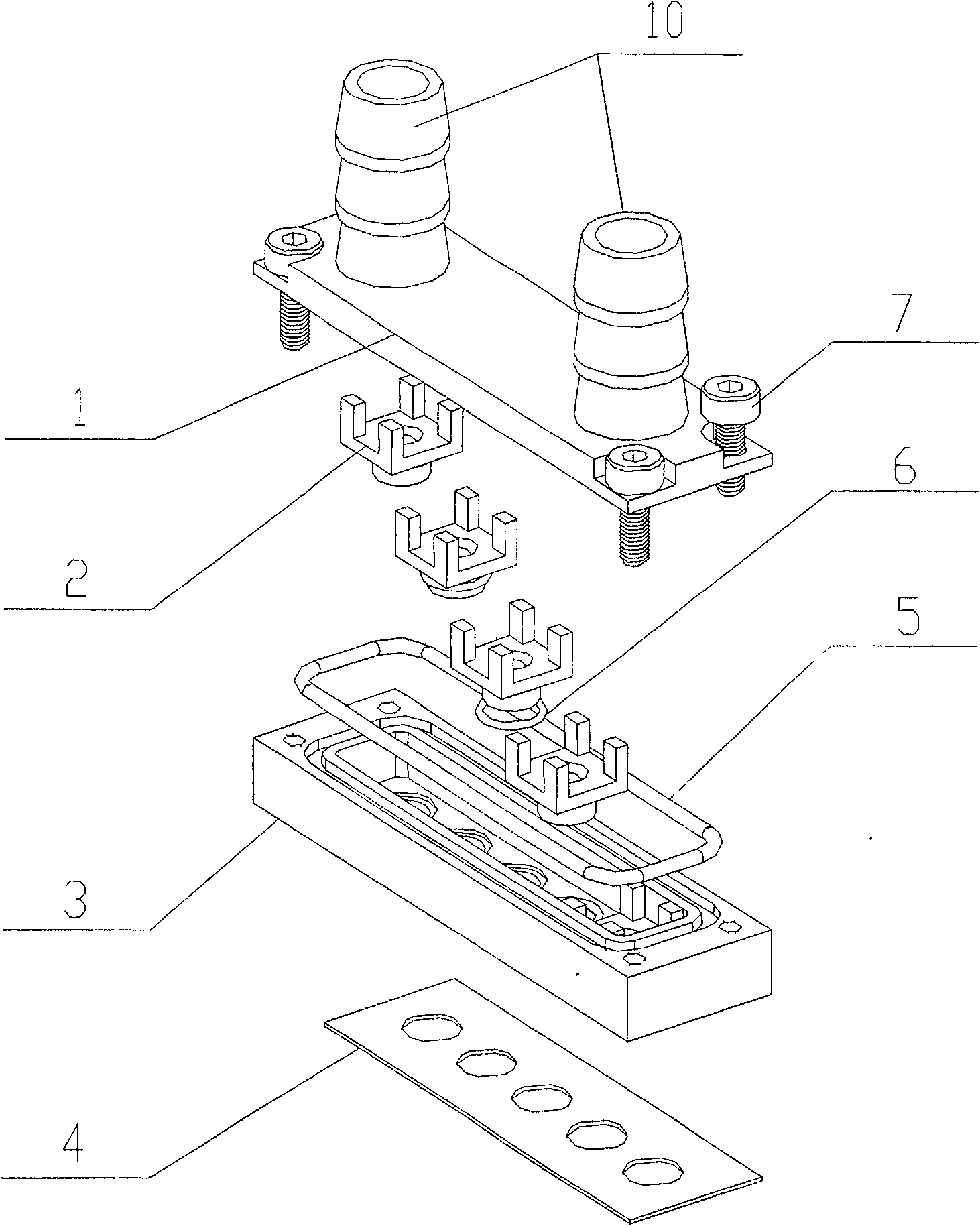

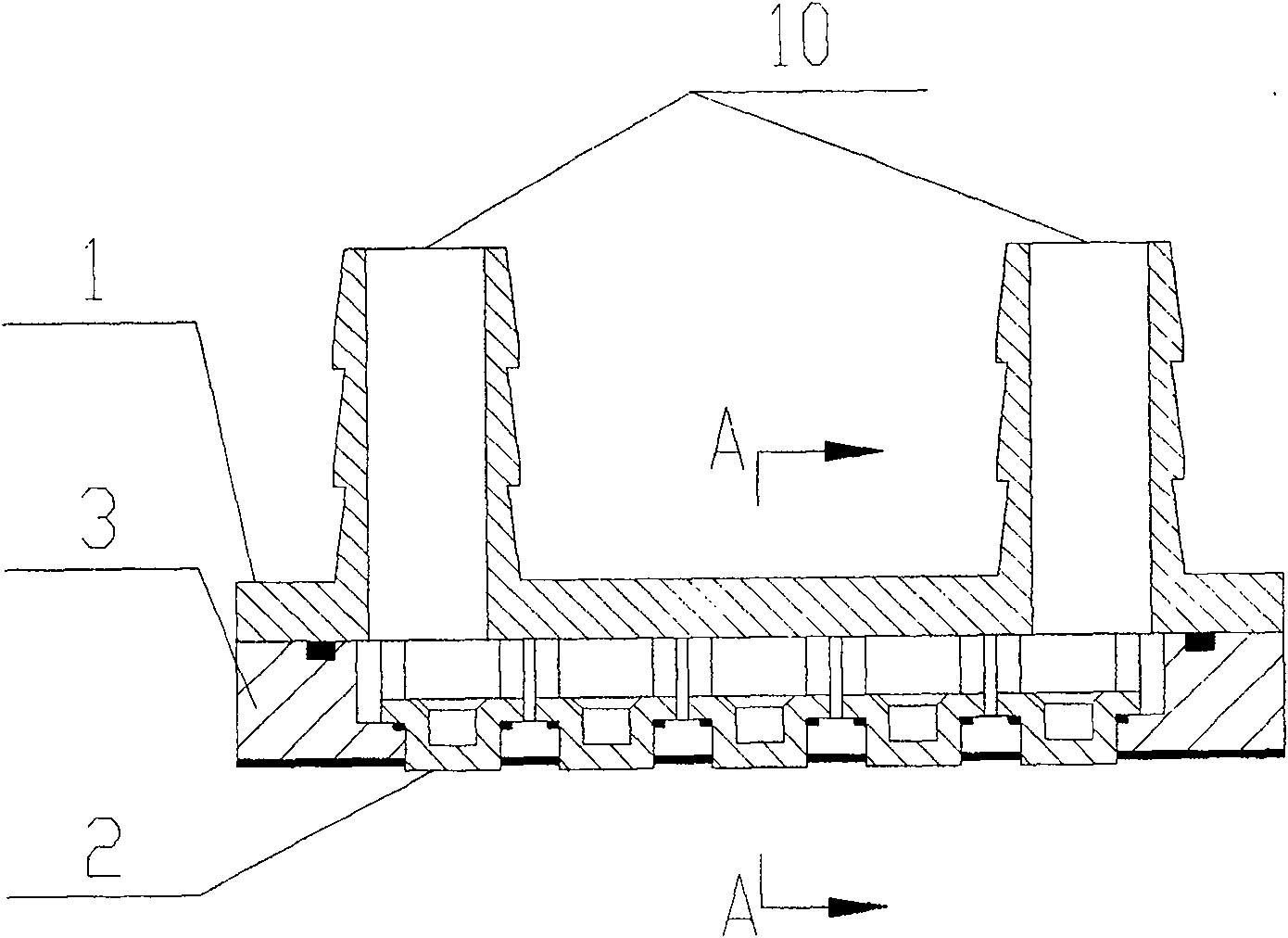

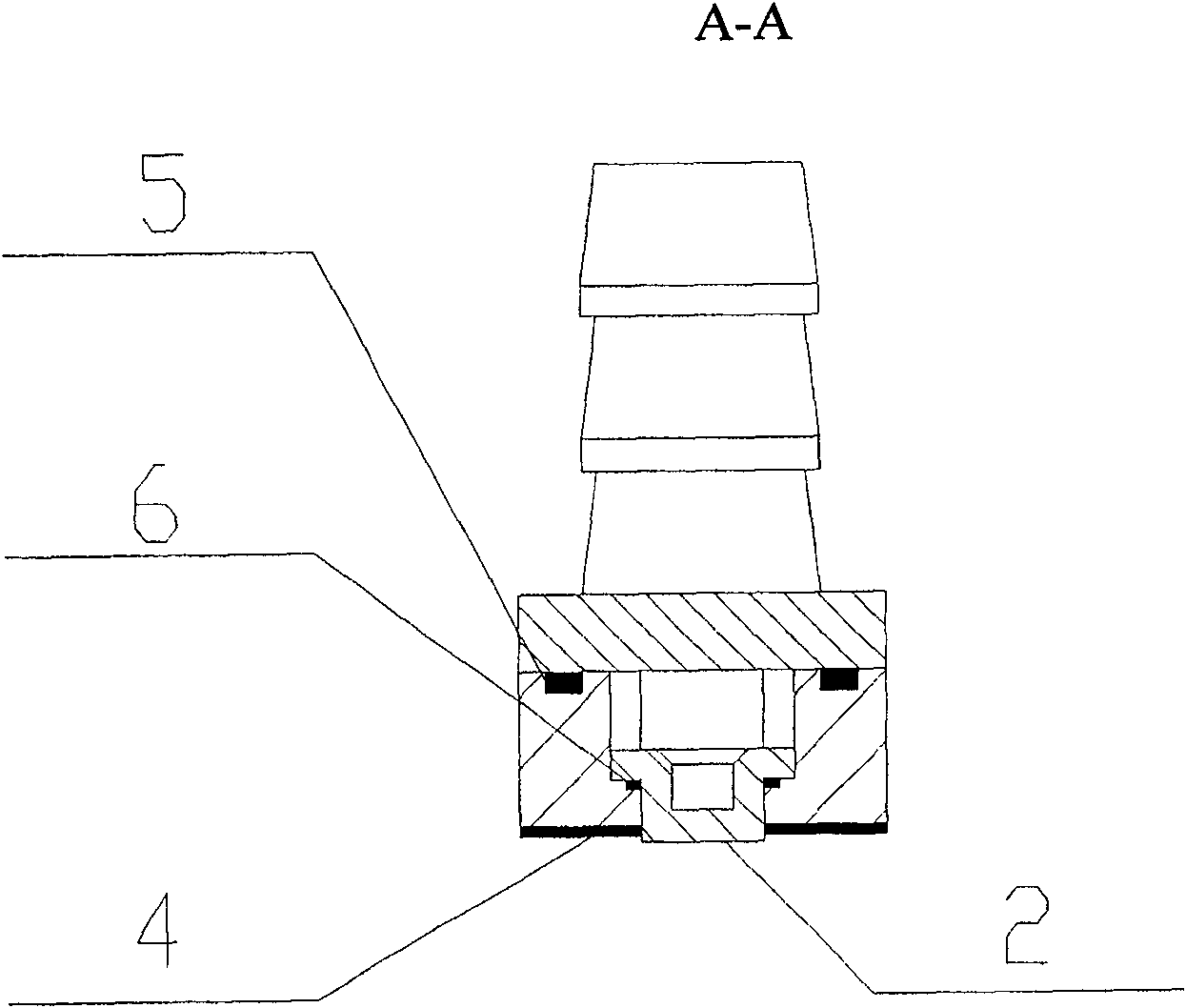

[0018] Such as figure 1 , Figure 2a , Figure 2b The slat-type single-core laser diode array structure shown includes: a cover plate 1, a single-core tube 2, a cavity 3, an insulating layer 4, a rubber sealing strip 5, an O-ring 6, and a screw 7. The single-core tube 2 is installed in the cavity 3, the cover plate 1 is covered on the cavity 3, the single-core tube 2 and the cavity 3 are sealed with an O-ring 6, and the cavity 3 and the cover plate 1 are sealed with Rubber sealing strip 5 is sealed. The single-core tube 2 uses a heat sink 21 with high thermal conductivity and easy processing as a heat dissipation base. It is composed of upper and lower parts 22 and 24. The lower part 24 is a cylinder, and the single-core section 8 is fixed on the bottom plane of the cylinder. , milling holes inside the cylinder (see Figure 5 ), the purpose is to shorten the distance between the single-core joint 8 and the cooling liquid, to improve cooling efficiency, the upper half 22 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com