Three-D track measuring marking-off method for segment of cable tower

A technology of three-dimensional tracking and steel cable tower, which is applied to measuring devices, instruments, and optical devices, etc., can solve the problems of complicated operation process, low efficiency, and inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

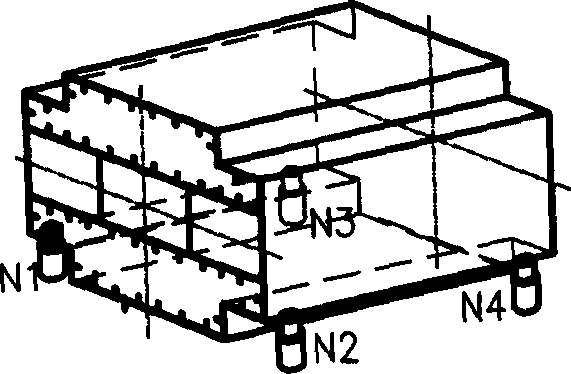

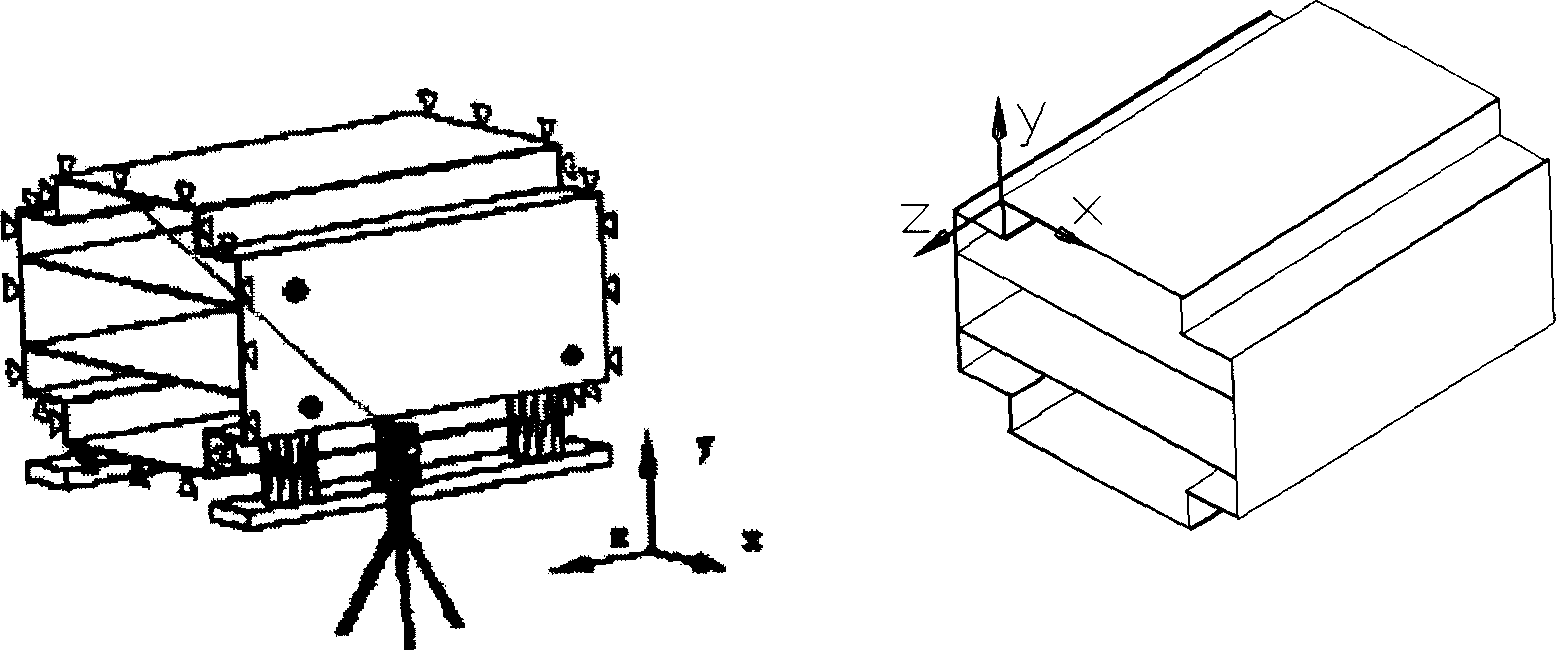

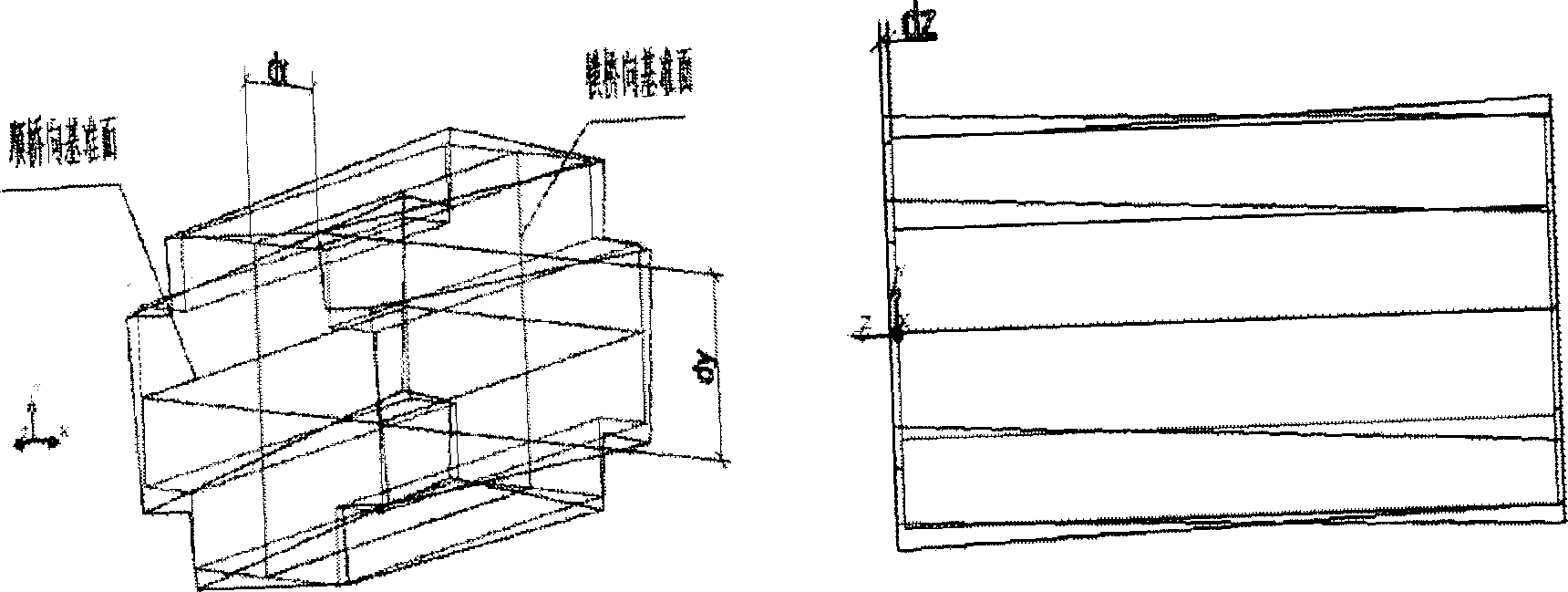

[0048] Embodiment 1: with reference to attached Figure 1~5 . Steel cable tower segmental space measurement method, (1) workpiece state control:

[0049] ① Requirements for supporting reaction force:

[0050] | N 1 - N 2 | N 1 + N 2 ≤ 0.05 , In the formula, N1 and N2 represent the support reaction force, N1-N2 represents the support reaction force difference, N1+N2 represents the support reaction force sum,

[0051] | N 3 - N 4 | N 3 + N 4 ≤ 0.05

[0052] In the formul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com