Method for treating ammonia nitrogen in charking deposed ammonia

A technology of ammonia water and ammonia nitrogen, which is applied in the direction of chemical instruments and methods, separation methods, water/sewage treatment, etc., can solve the problem that wastewater is difficult to meet the national water quality discharge standards, the load of activated sludge biochemical treatment is large, and the removal rate of total ammonia nitrogen is low, etc. problems, to achieve significant energy-saving effects, reduce energy consumption, and reduce the ammonia nitrogen load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

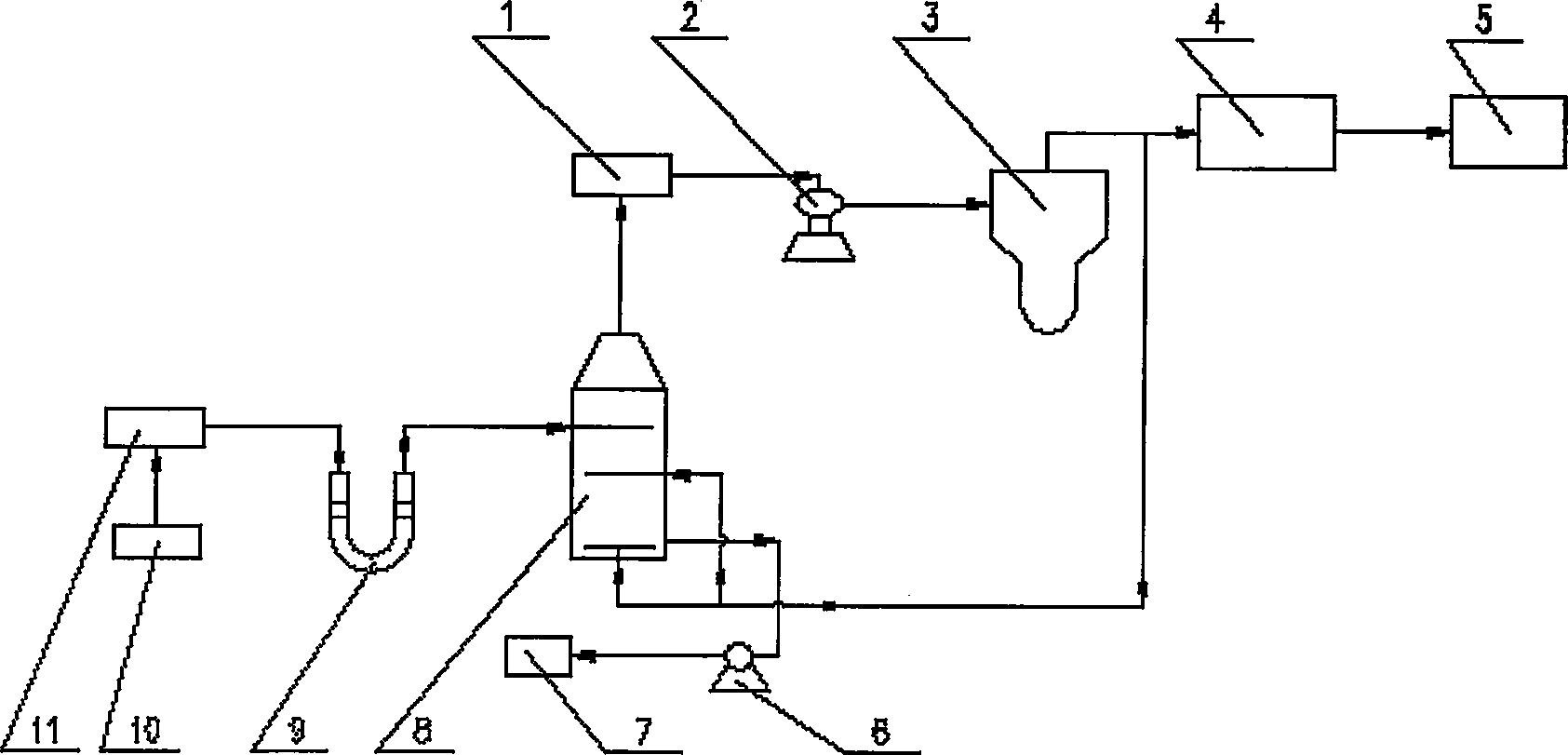

[0022] The technology of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] The chemical composition of a coking waste ammonia water [11] is: total ammonia 2-5g / L, volatile ammonia 1-2g / L, CO 2 1~2g / L, sulfide 0.2~2g / L, cyanide 0.04~0.14g / L, volatile phenol 1.3~2.5g / L, temperature 70~80℃. The technological process for treating ammonia nitrogen in the waste ammonia is as follows: figure 1 Shown:

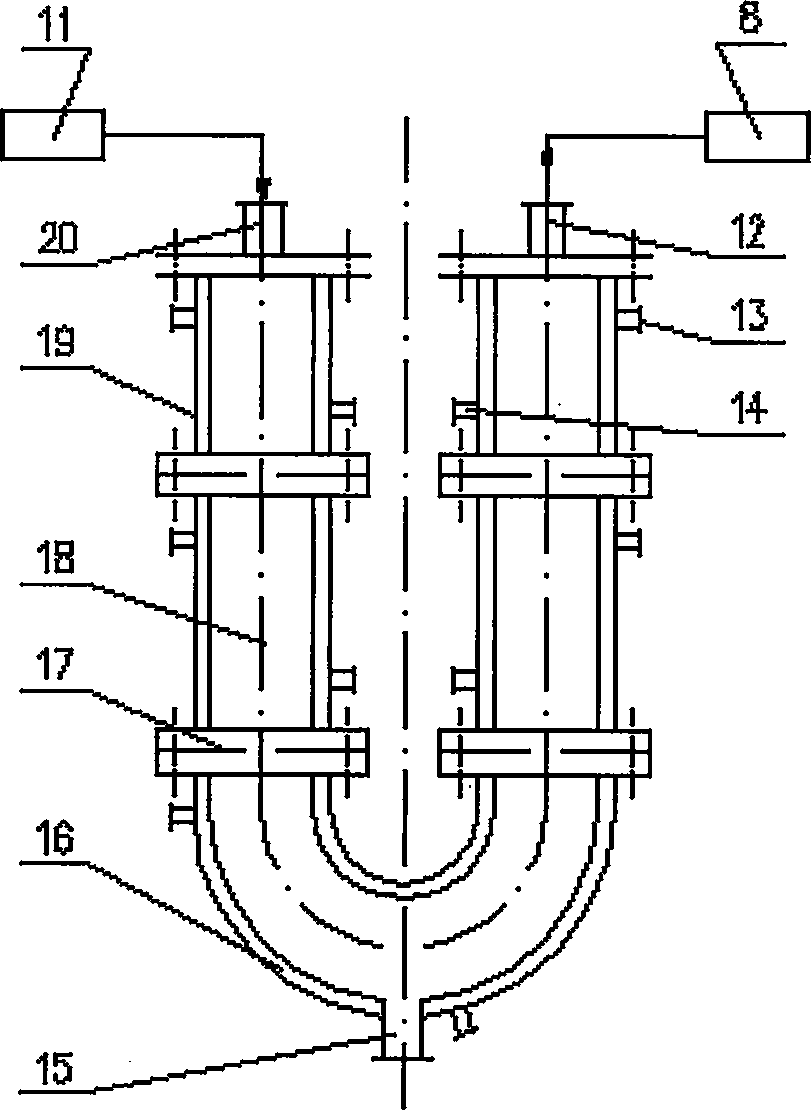

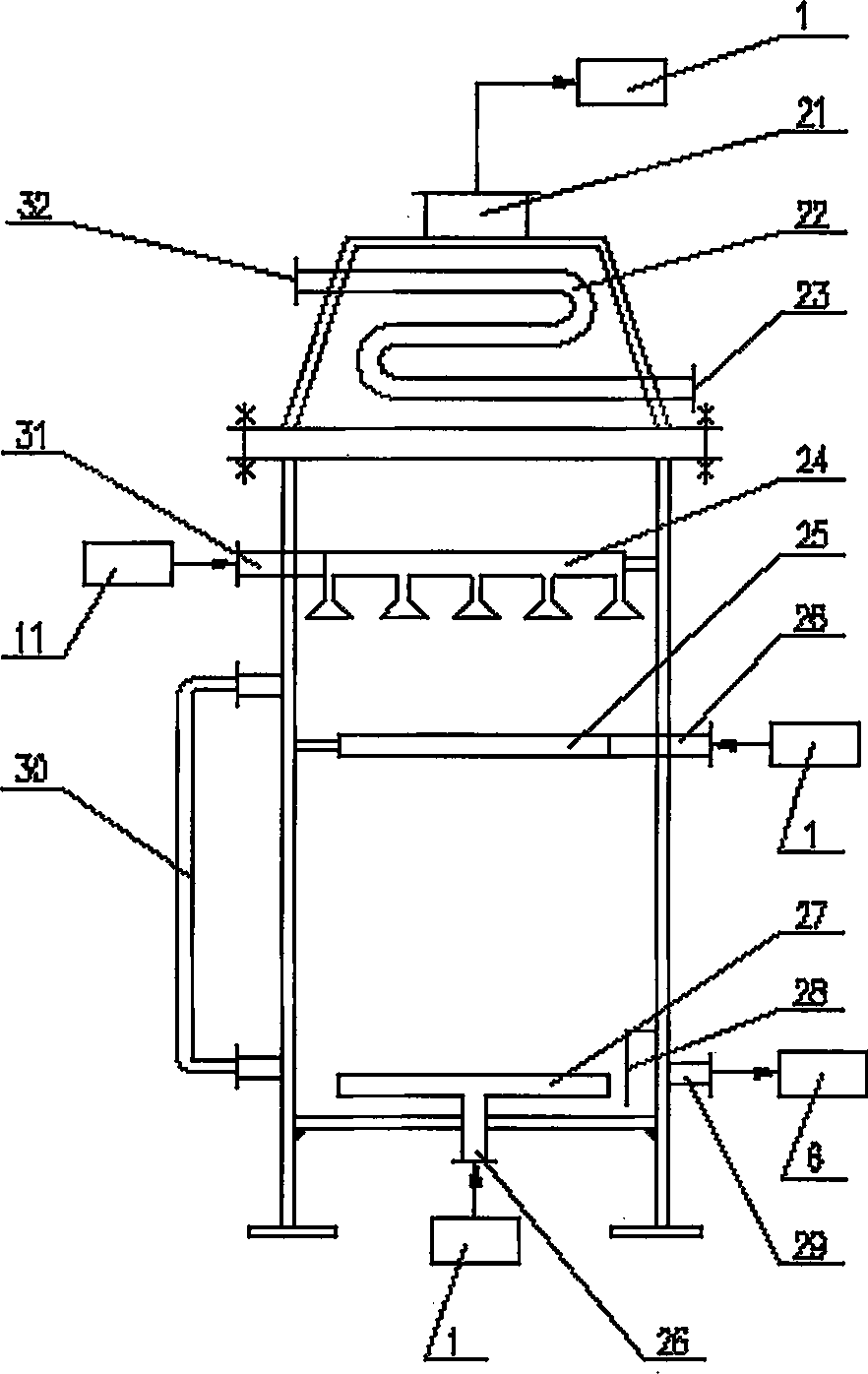

[0024] First add 15-35g / L Na in the above coking waste ammonia water [11] 2 CO 3 As a removal agent [10], adjust the pH value to 10-12, and then add Na 2 CO 3 The waste ammonia water [11] of removal agent [10] is sent into such as by pipeline figure 2 As shown, or adopt "a kind of fixed ammonium salt reactor" (CN200610019288.2), or adopt "a kind of cyclone reactor" (CN200620097103.5). The waste ammonia water [11] passes through the swirl plate [17] installed between each heat carrier jacket [19] from the liquid inlet [...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap