Valve for switching double gas supplies in use for fuel gas heating apparatus

A technology of dual gas sources and switching valves, which is applied in the direction of multi-way valves, valve devices, engine components, etc., can solve the problems of dual gas source gas heaters without suitable gas source switching valves, etc., so as to facilitate the organization of production and sales, and facilitate Distributors and manufacturers, the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

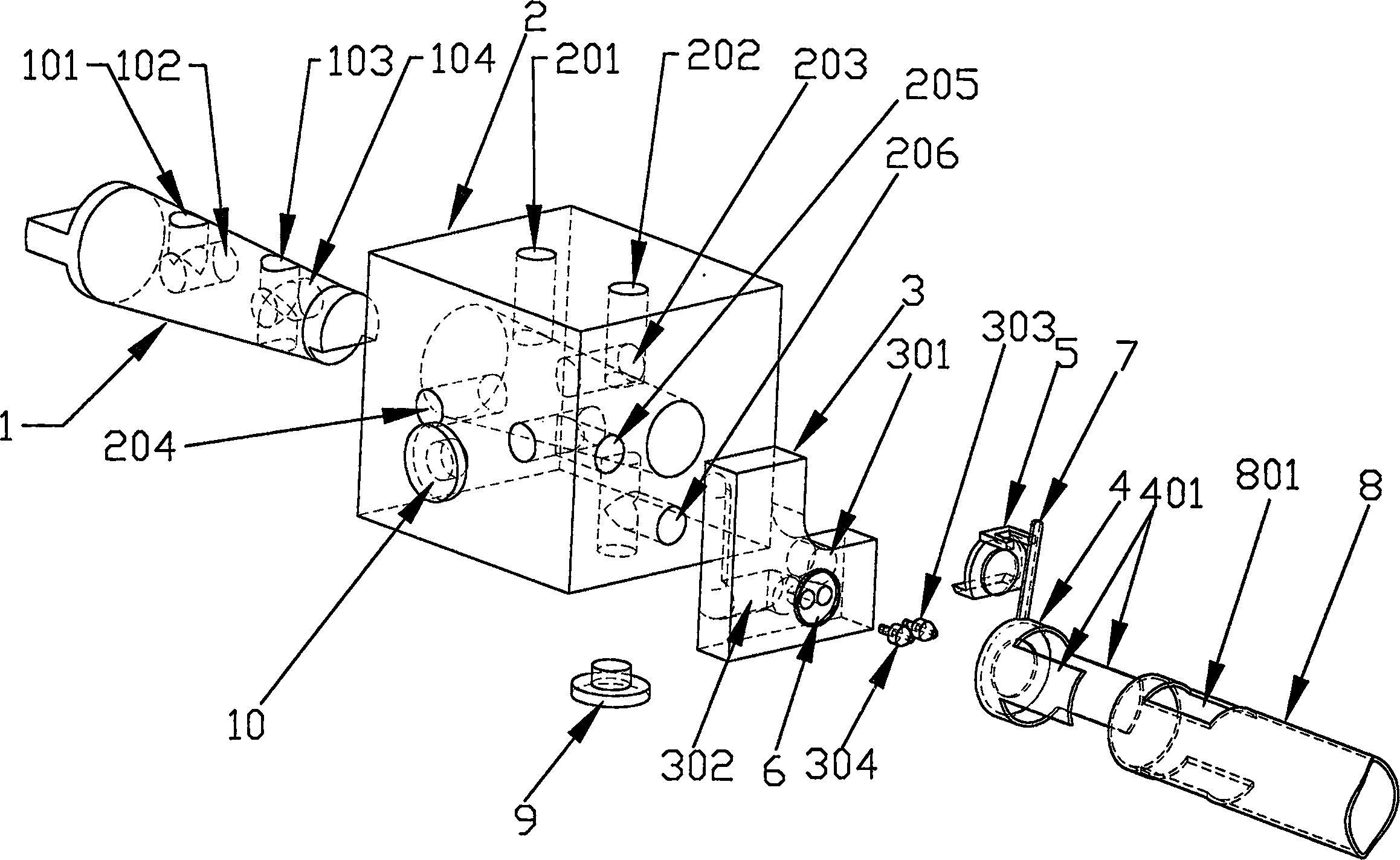

[0018] Such as figure 1 shown.

[0019] A dual gas source conversion valve for a gas heater, which includes a valve core 1 with a knob, a main valve body 2, a nozzle assembly 3 and a primary air inlet adjustment sleeve 4, wherein the nozzle assembly 3 and the main valve body 2 can be It is an integral structure, and it can also be a split structure as shown in the figure. The main valve body 2 is provided with an ODS inlet channel 201, a gas inlet channel 202, a high calorific value gas ODS outlet channel 203, and a low calorific value gas ODS outlet channel. 204, high calorific value gas outlet channel 205, low calorific value gas outlet channel 206, the nozzle assembly 3 is provided with an air channel 301 connecting the high calorific value gas outlet channel 205 and the high calorific value gas nozzle 303 and connecting the low calorific value gas outlet channel 206 and The air channel 302 of the low calorific value gas nozzle 304, the valve core 1 is provided with a chan...

Embodiment 2

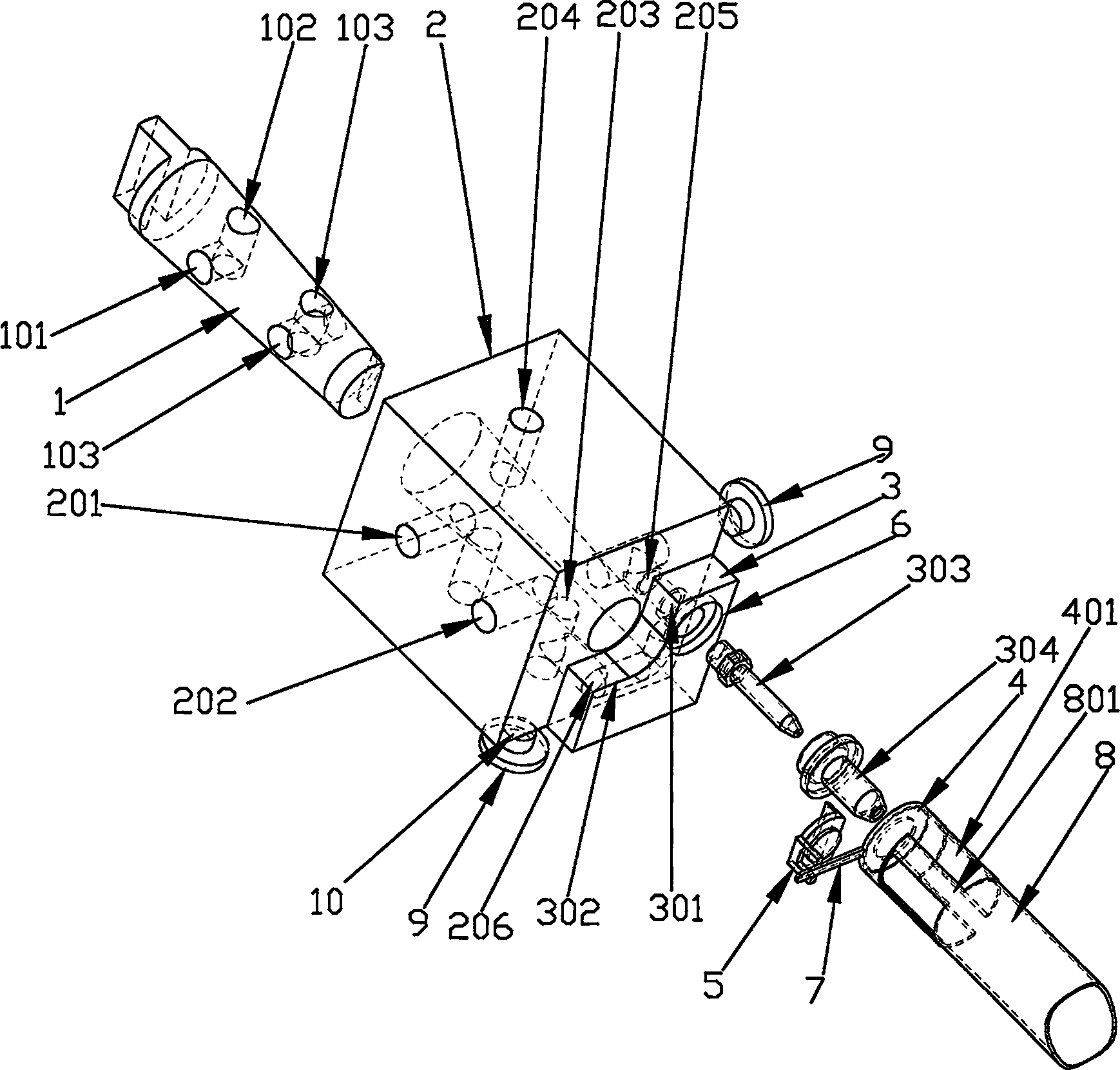

[0021] Such as figure 2 shown.

[0022] A dual gas source conversion valve for a gas heater, which includes a valve core 1 with a knob, a main valve body 2, a nozzle assembly 3 and a primary air inlet adjustment sleeve 4, wherein the nozzle assembly 3 and the main valve body 2 can be It is an integral structure, and it can also be a split structure as shown in the figure. The main valve body 2 is provided with an ODS inlet channel 201, a gas inlet channel 202, a high calorific value gas ODS outlet channel 203, and a low calorific value gas ODS outlet channel. 204, high calorific value gas outlet channel 205, low calorific value gas outlet channel 206, the nozzle assembly 3 is provided with an air channel 301 connecting the high calorific value gas outlet channel 205 and the high calorific value gas nozzle 303 and connecting the low calorific value gas outlet channel 206 and The air channel 302 of the low calorific value gas nozzle 304, the valve core 1 is provided with a cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com