Rear projection type screen

A screen and rear projection technology, applied in the field of rear projection screens, can solve the problems of increasing the number of components, easy electrification of the screen, and deterioration of image quality, and achieve the effects of prolonging the life of the light source, stabilizing the display quality, and reducing the price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

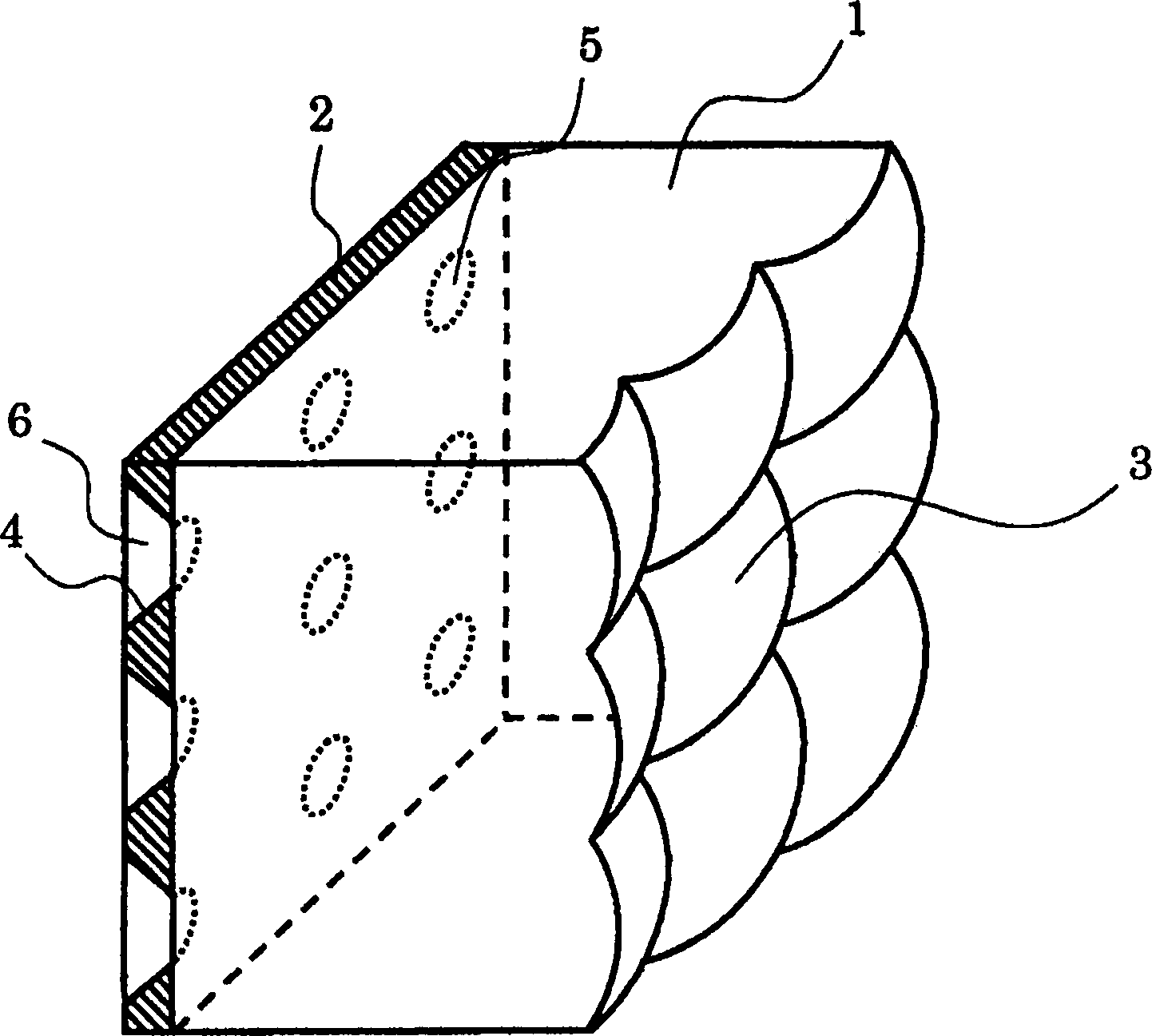

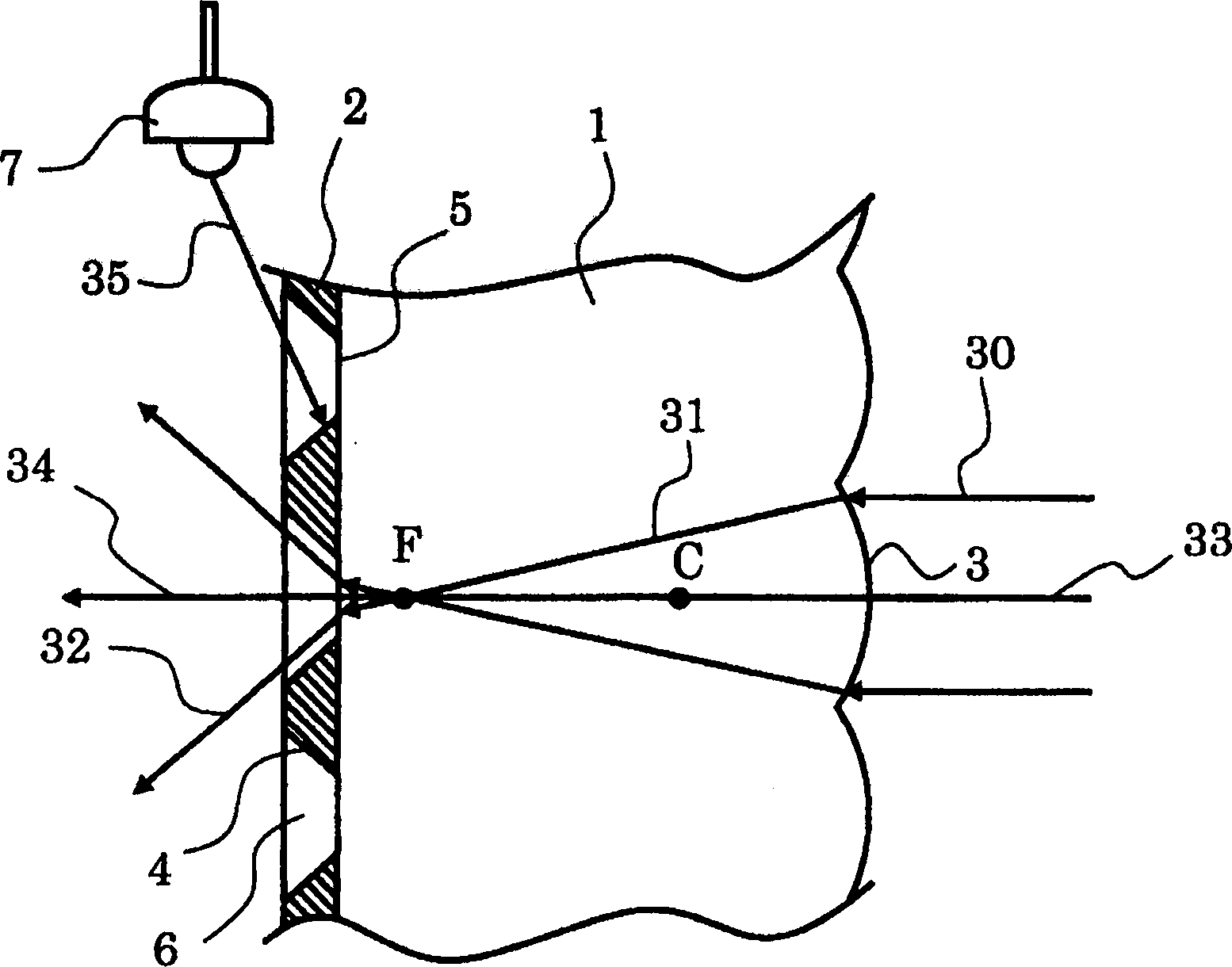

[0081] figure 1 It is an enlarged perspective sectional view of main parts showing an embodiment of the rear projection screen of the present invention. exist figure 1 Among them, the microlens array sheet 1 is a transparent sheet with microlenses 3 formed on one surface. The microlens 3 is a microlens whose surface is formed of a spherical surface, an elliptical surface, an aspheric surface, or the like. It is formed into a shape suitable for various conditions such as usage. The microlens array sheet 1 can be made of transparent polymer materials such as acrylic resin, polycarbonate resin, cycloolefin resin, and polyethylene resin.

[0082] The microlens 3 is formed as a spherical surface, an elliptical surface, or the like with the center of the area divided into squares or rectangles as the center of symmetry. The pitch of the regions divided into squares or rectangles is 100 to 500 μm, typically preferably 150 to 220 μm.

[0083] In addition, the thickness of the m...

Embodiment 2

[0102] FIG. 5 shows an enlarged schematic cross-sectional view of another embodiment of the rear projection screen of the present invention. Figure 5 shows the embodiment with figure 1 The embodiment shown differs in that the pinhole 5 is square or rectangular in shape and the opening 6 is in the shape of a quadrangular truncated pyramid. Functions related to other parts are the same as those in Embodiment 1, and therefore description thereof will be omitted.

[0103] In the embodiment shown in FIG. 5 , the shape of the pinhole 5 is square or rectangular, and the shape of the opening 6 is a quadrangular truncated pyramid, so that the directional light-absorbing sheet 2 can have anisotropy in the vertical direction and the left-right direction. As described above, external light from lighting, windows, etc. is often incident on the screen from the vertical direction and the left and right directions. Due to this structure, various external light can be effectively blocked.

...

Embodiment 3

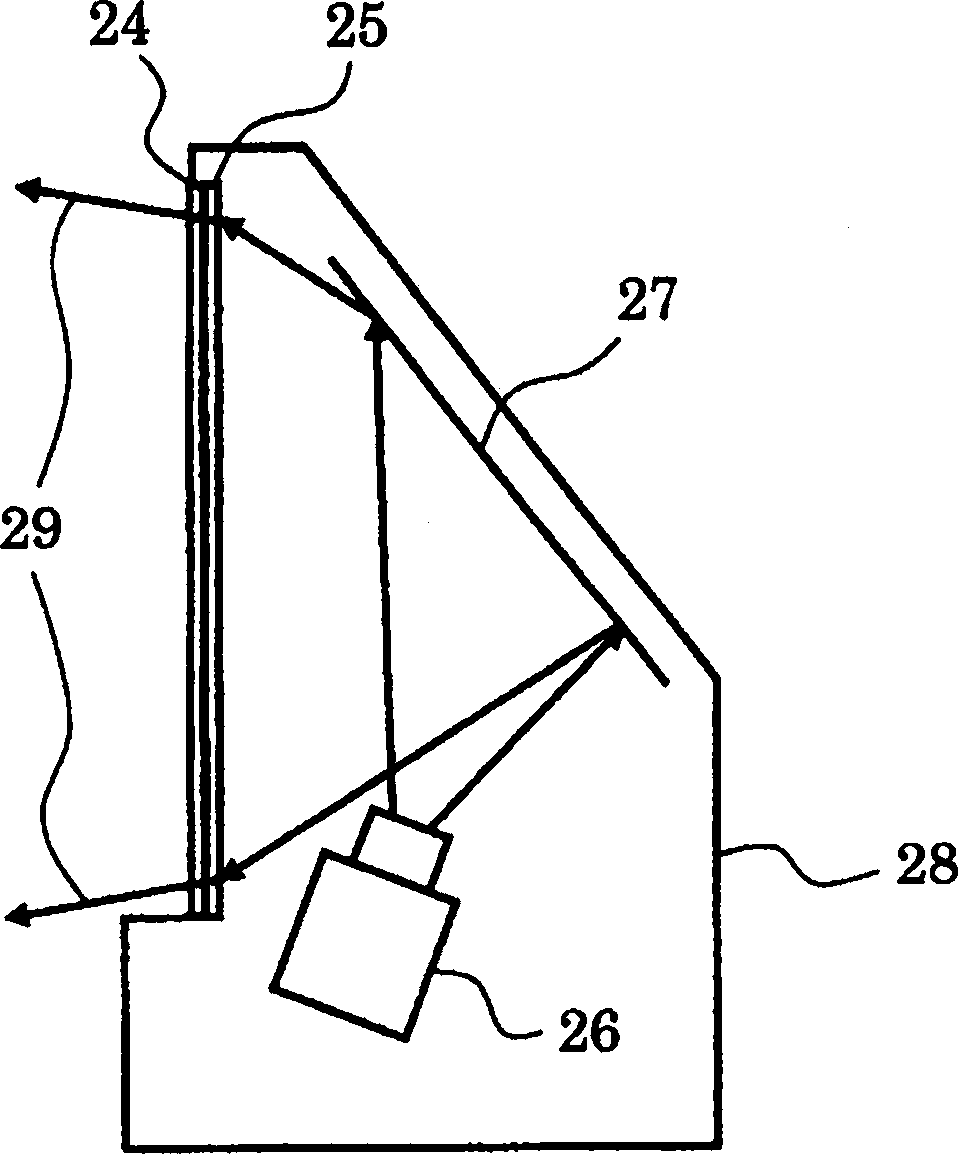

[0107] Image 6 An enlarged cross-sectional schematic view showing an embodiment of the rear projection screen of the present invention. Image 6 and Figure 4 The difference is that the light-scattering particles 1 are filled in the openings formed on the directional light-absorbing sheet 2 together with a transparent adhesive.

[0108] Such as Figure 4 As shown, by shifting the position of the pinhole 5 outward at the edge of the screen, the light from the projector can be effectively emitted from the screen surface. The radiation distribution is different and therefore the viewing angle dependence is different. That is, the brightness of the image on the screen differs depending on the angle from which the screen is viewed.

[0109] exist Image 6 In this case, even in this case, the variation in the radiation distribution of the light emitted from the screen can be reduced, and the image on the screen can be observed with the same brightness no matter from which angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com