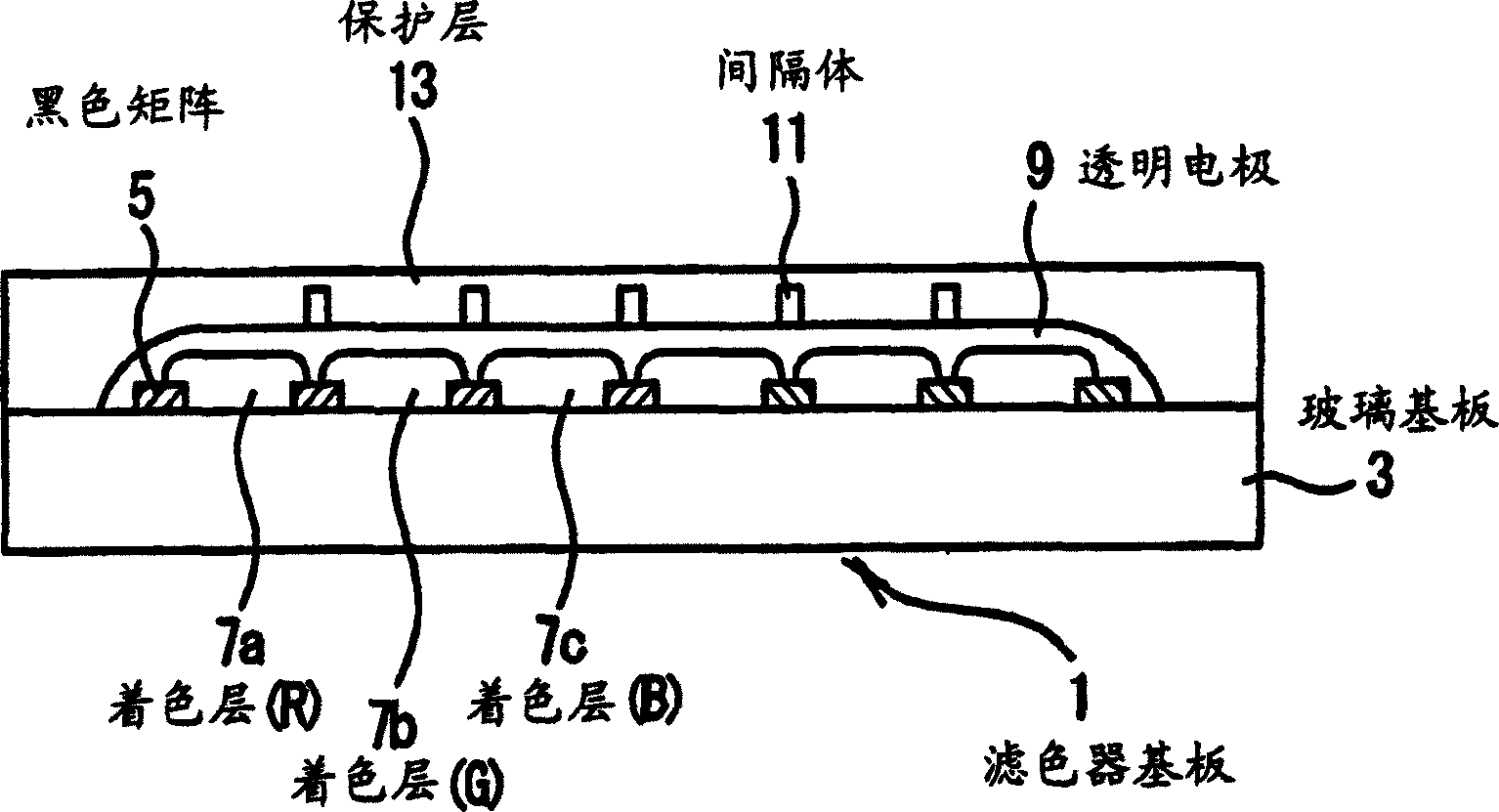

Color filter substrate, layered body of color filter substrates, and method of using the color filter substrate

A technology of color filter substrates and laminates, applied in instruments, optical filters, optics, etc., can solve the problems of easy breakage, storage containers, transportation difficulties, etc., and achieve the effect of good operability and small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0123] Hereinafter, it will explain in detail based on an Example.

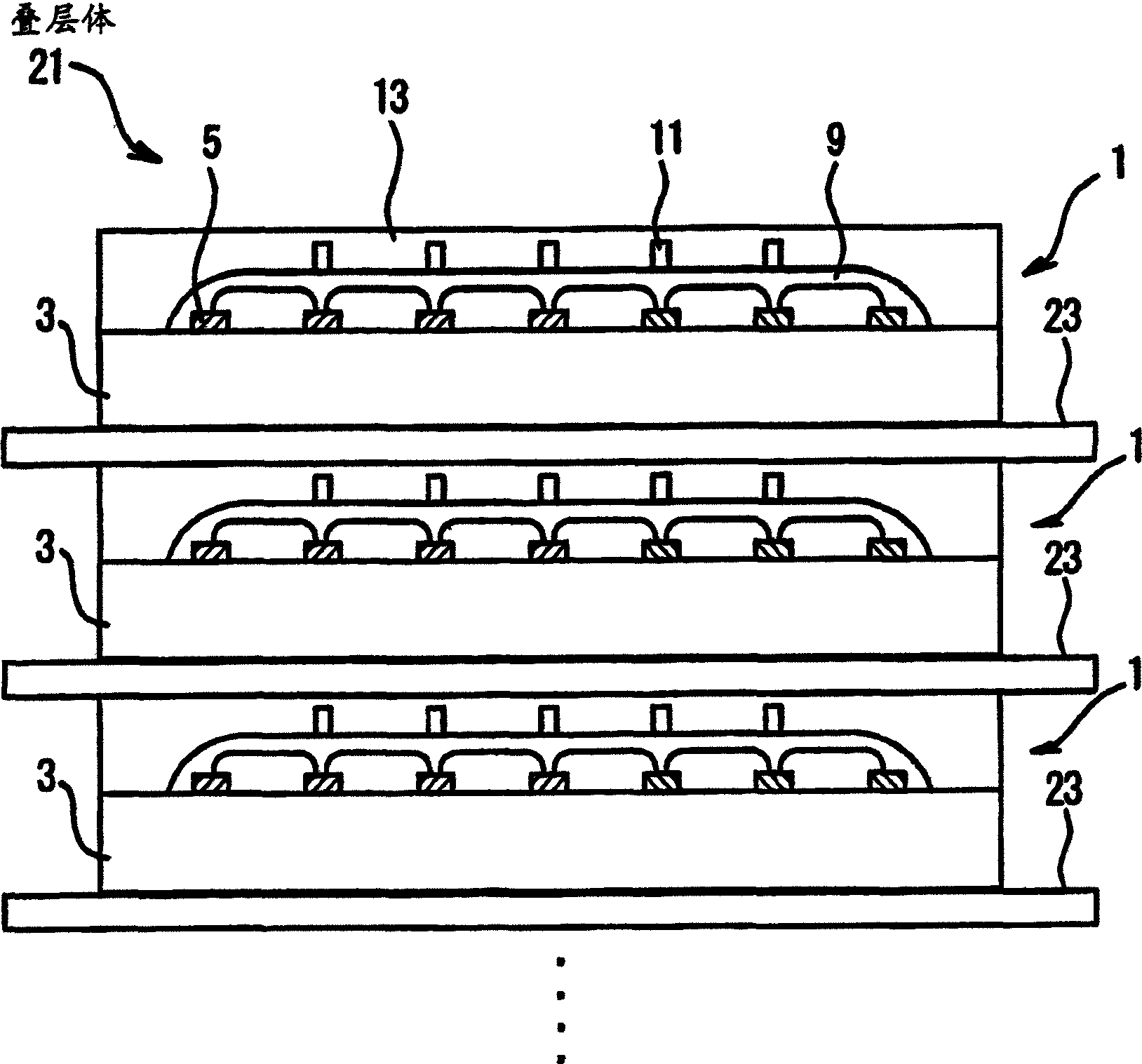

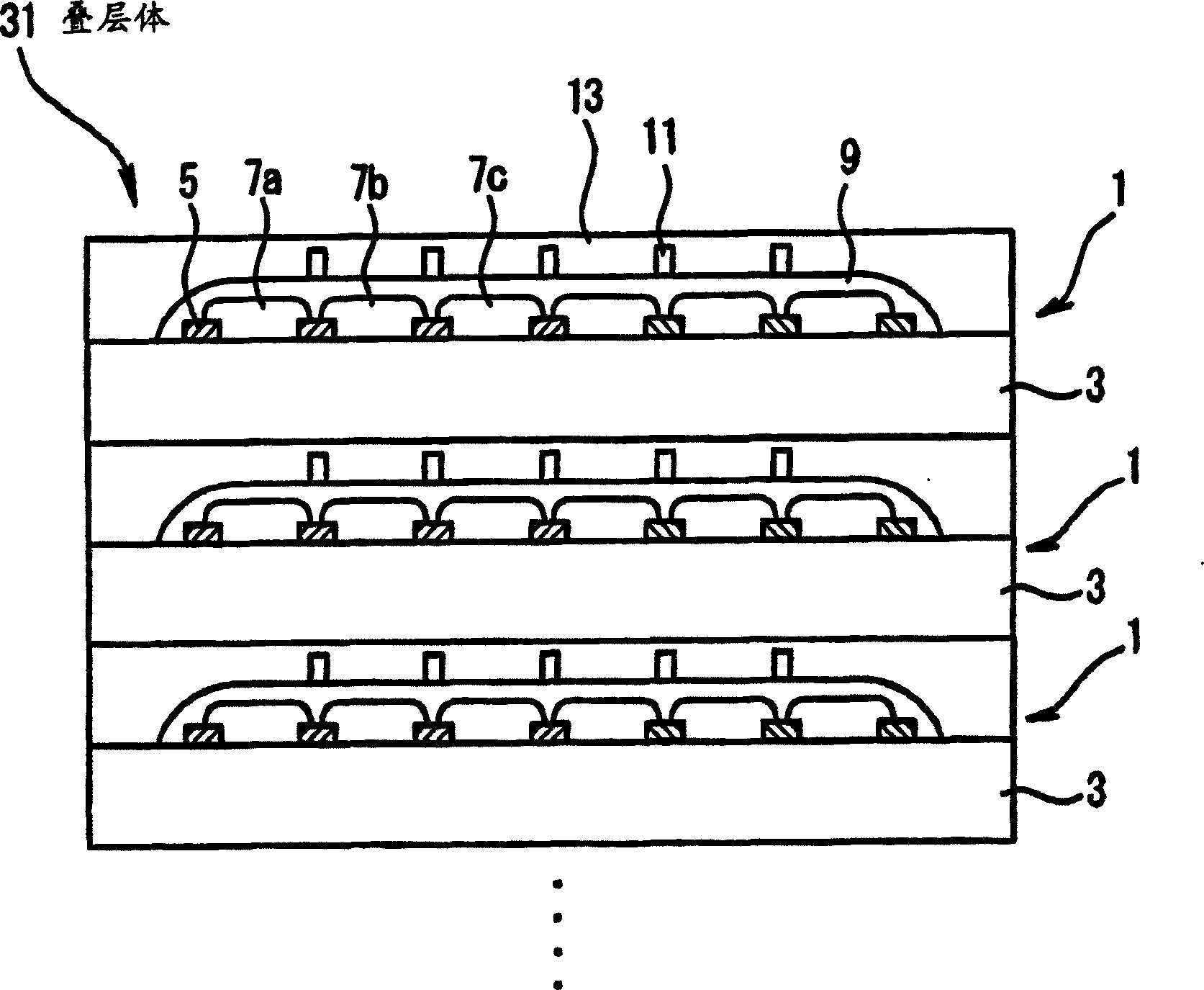

[0124] After the surface of the colored layer side of the color filter substrate with a size of 1500 mm in length and 1800 mm in width is coated with a 10% aqueous solution of ゴ-セノ-ル NK-05 manufactured by Nippon Synthetic Chemical Industry Co., Ltd. with a roll coater, it is dried in an oven at 80°C Dry in medium for 10 minutes to obtain a protective layer consisting of a coating layer with a thickness of 5 μm.

[0125] In order to prevent the adjacent substrates from sticking together as if they were integrated due to the high planar accuracy of the substrates, between the adjacent color filter substrates, HZ50 (polyethylene film) (length 1520 mm × width) made by Toseiro Co., Ltd. was sandwiched. 1780mm), while storing 200 color filter substrates protected by the coating layer on a dedicated pallet that can be stored in a state that can be tilted at an angle of 15 degrees from the vertical state.

[0126] T...

Embodiment 2

[0131] KAYAMIRROR TOC-301 (acrylic resin) manufactured by Nippon Kayaku Co., Ltd. was coated with a roll coater on the colored layer side surface of a color filter substrate having a length of 1500 mm and a width of 1800 mm, and dried in an oven at 80° C. for 10 days. minutes, a protective layer consisting of a coating layer with a thickness of 5 μm was obtained.

[0132] In order to prevent the adjacent substrates from sticking together as if they were integrated due to the high planar accuracy of the substrates, between the adjacent color filter substrates, HZ50 (polyethylene film) (length 1520 mm × width) made by Toseiro Co., Ltd. was sandwiched. 1780mm), while storing 200 color filter substrates protected by the coating layer on a dedicated pallet that can be stored in a state that can be tilted at an angle of 15 degrees from the vertical state.

[0133] Then, for the purpose of blocking the outside air and preventing loose packaging, an elastic film is wrapped to form a l...

Embodiment 3

[0138] The surface of the colored layer side of a color filter substrate with a size of 1500 mm in length and 1800 mm in width was coated with Saran Resin F216 manufactured by Asahi Kasei Industry Co., Ltd. with a roll coater, and dried in an oven at 80° C. for 10 minutes to obtain a 5 μm-thick film. A protective layer composed of a coating layer.

[0139] In order to prevent the adjacent substrates from sticking together as if they were integrated due to the high planar accuracy of the substrates, between the adjacent color filter substrates, HZ50 (polyethylene film) (length 1520 mm × width) made by Toseiro Co., Ltd. was sandwiched. 1780mm), while storing 200 color filter substrates protected by the coating layer on a dedicated pallet that can be stored in a state that can be tilted at an angle of 15 degrees from the vertical state.

[0140] Then, for the purpose of blocking the outside air and preventing loose packaging, an elastic film is wrapped to form a laminate for colo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com