Crucible for preparing crystal by high-temperature gas phase process and use method thereof

A high-temperature gas and crucible technology is applied in the field of crucibles for preparing crystals by a high-temperature gas-phase method, and can solve the problems of low heat transfer efficiency, low heat transfer efficiency, and difficulty in forming temperature gradients in the crucible.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

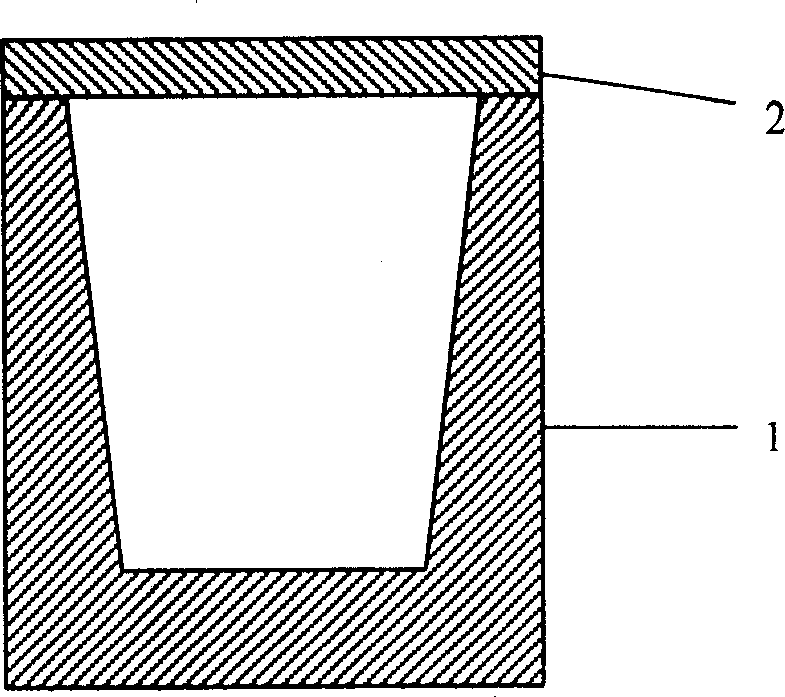

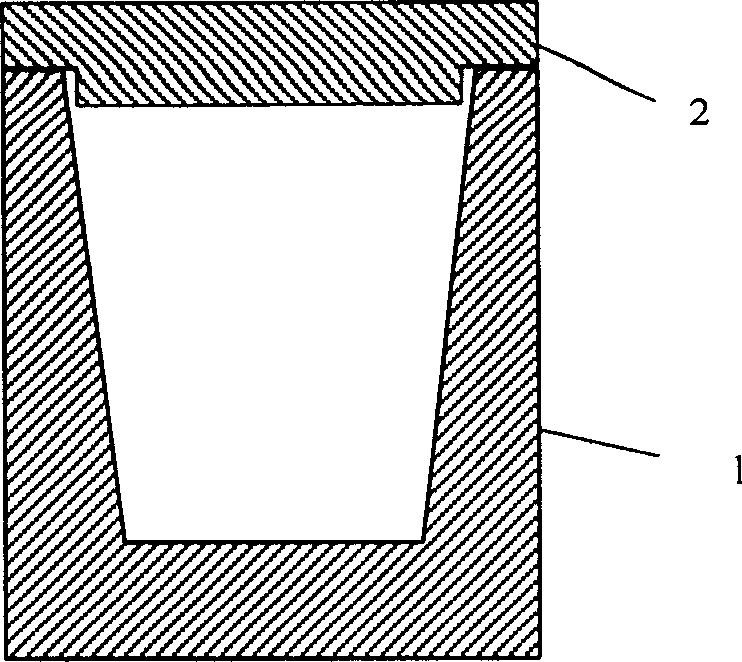

[0013] Crucible of the present invention such as figure 1 with figure 2 As shown, it is composed of a crucible body (1) and a crucible cover (2). The crucible cover is a disc or a disc with a boss shape that can be buckled downward. The crucible cover is directly pressed on the top of the crucible. The inside of the crucible body is a round The shape of the table, the top is large and the bottom is small, the wall of the crucible gradually becomes thicker from top to bottom, so that during the induction heating process of the crucible, the heat is less at the top and more at the bottom, resulting in a temperature field distribution in the crucible.

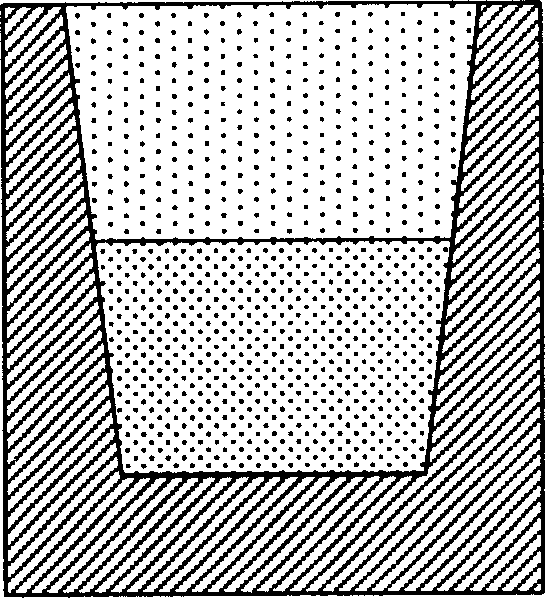

[0014] When the crucible of the present invention is used to prepare crystals by high-temperature gas-phase method, its use method is relatively unique. In the process of use, first put the material into the crucible, and burn the material into a frustum-shaped sintered block in the protective gas at a temperature slightly lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com