Preparation method of lithium phosphate catalysts

A catalyst and lithium phosphate technology, applied in the direction of catalyst activation/preparation, isomerization preparation, chemical instruments and methods, etc., can solve problems such as cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Lithium Phosphate Catalyst Containing Sodium and Boron

[0032] Catalyst preparation

[0033] In a first flask, 43.5 g of sodium phosphate dodecahydrate and 13 g of boric acid were dissolved in 150 ml of 70°C distilled water. In a second flask, 15.8 g of lithium hydroxide monohydrate and 4.6 g of sodium hydroxide were dissolved in 125 ml of 70°C distilled water. The solution from the first flask was then added to the second flask at 70°C under rapid stirring over a period of 10 minutes. The crude lithium phosphate white precipitate was collected by filtration. The filter cake was broken up by hand and stirred in a 2 liter flask with 1.6 liters of distilled water for 1.5 hours at 85-90°C. The white powder was collected by filtration, and then dried overnight in an oven at 130°C. The resulting catalyst contains about 0.1-0.3 wt% sodium and 0.3-0.5 wt% boron.

[0034] Isomerization of Propylene Oxide

[0035] The isomerization reaction was carried out in a glass r...

Embodiment 2

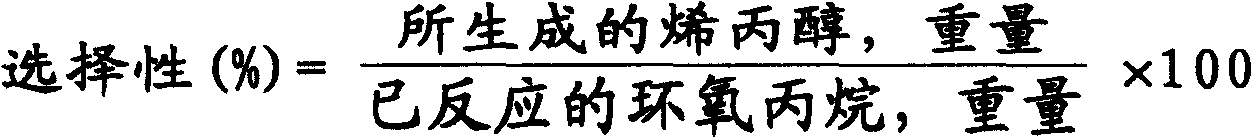

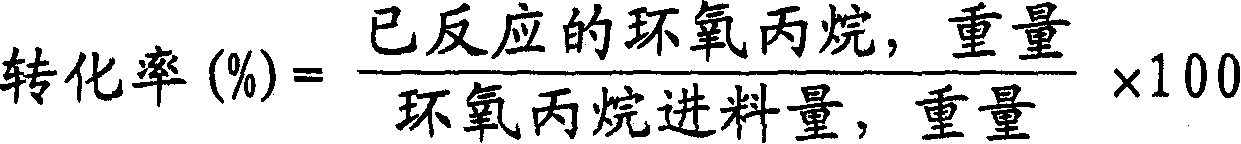

[0037] Lithium Phosphate Catalyst Containing Sodium and Boron

[0038] The overall procedure of Example 1 was repeated, except that 43.5 g of sodium phosphate dodecahydrate and 20 g of sodium tetraborate decahydrate were dissolved in the first flask. The resulting lithium phosphate catalyst contains about 0.1-0.3 wt% sodium and 0.3-0.6 wt% boron. The conversion rate of propylene oxide is in the range of 54.0%-58.7%, and the selectivity of allyl alcohol is in the range of 92.8%-93.0%.

Embodiment 7

[0052] Low Temperature Isomerization Using Sodium and Boron-Containing Lithium Phosphate Catalysts

[0053] The overall steps of Example 1 were repeated, except that the isomerization reaction was carried out at 253°C. The conversion of propylene oxide ranged from 39.9% to 42.5% and the selectivity to allyl alcohol ranged from 93.6% to 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com