Device for reclaiming plastic and bottles

A recovery device and plastic recycling technology, applied in the direction of solid separation, separation of solids from solids with airflow, chemical instruments and methods, etc., can solve the problems of harsh working environment and low work efficiency, and achieve simple operation and maintenance, Low construction cost and operating cost, simple and reasonable device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

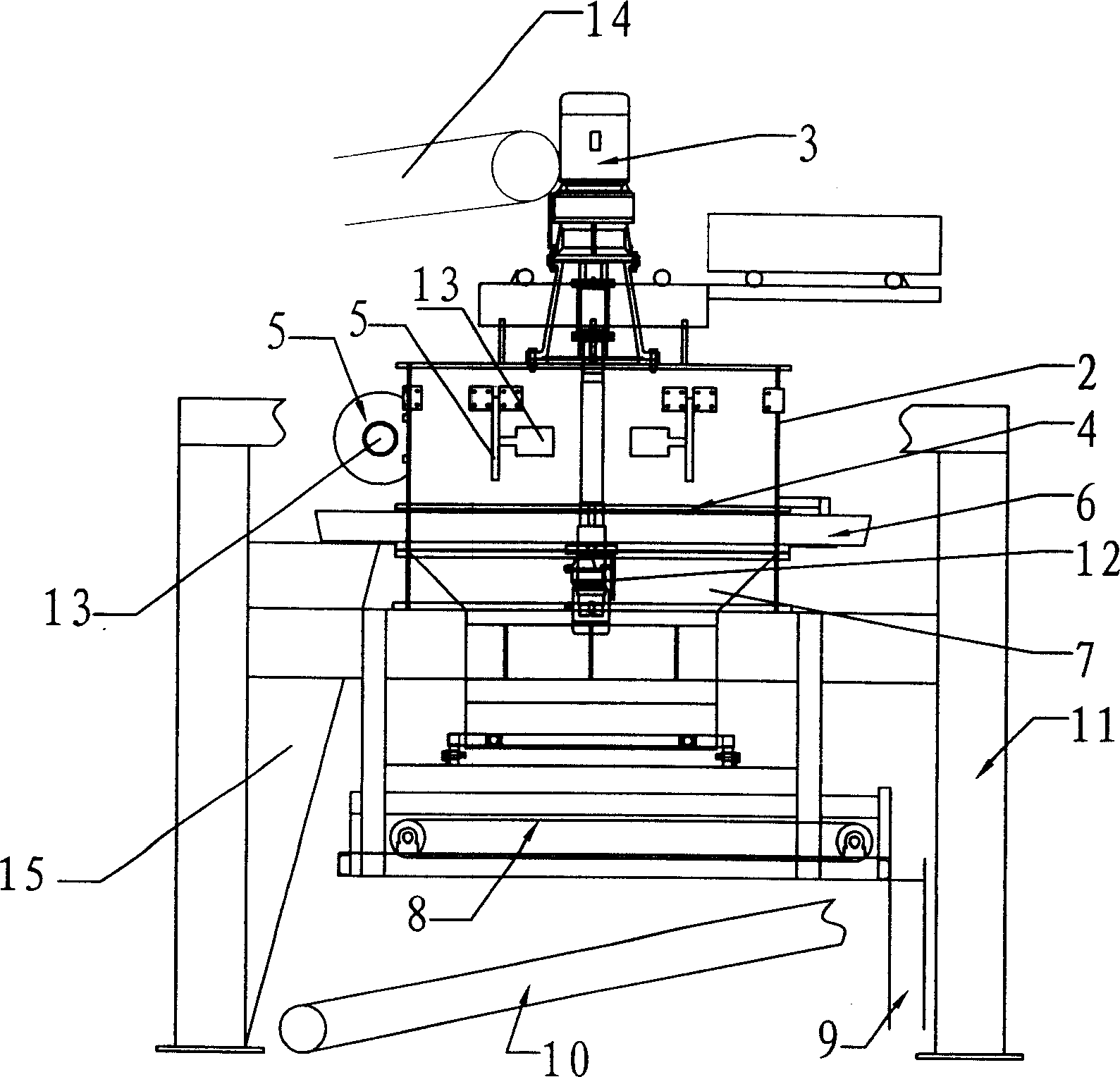

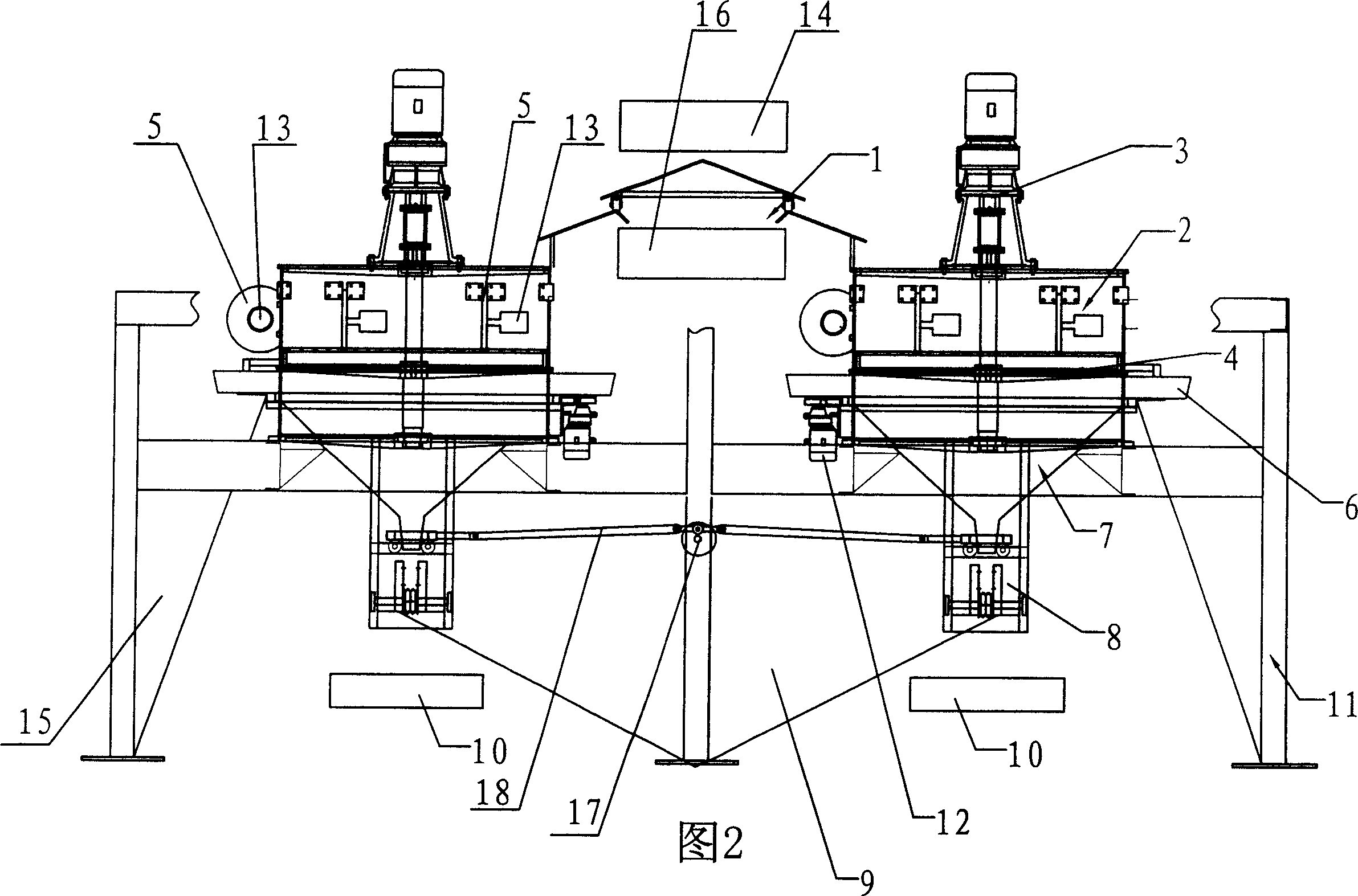

[0022] according to figure 1 With Fig. 2 and the device of the present invention of above-mentioned structure, design is that two described in Fig. 2 run side by side, belt conveyer 14 below the blanking end are provided with a herringbone dual-purpose blanking chute 1, and this blanking chute 1 can be moved by the upper part. The horizontally moving herringbone chute is composed of two sides chute respectively located on both sides of the herringbone chute and docked with its lower end. Described herringbone chute below also is provided with a belt conveyer 16; When what belt conveyer 14 sent is pure construction waste (concrete, brick slag etc.), then remove described herringbone chute 1, make rubbish fall to belt conveyer 16 is sent away without sorting by the device; otherwise, the incoming material enters the two devices through the herringbone dual-purpose blanking chute 1; the diameter of the cylinder 2 is designed to be 0.8-2M, and the six pointed The toothed cutterhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com