Method for improving biological denitrification dephosphorization efficiency by using ultrasonic

A technology for nitrogen and phosphorus removal and biological nitrogen removal, applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc. The effect of reaching the standard, improving the ability of microorganisms to remove nitrogen and phosphorus, and alleviating the problem of eutrophication in water bodies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

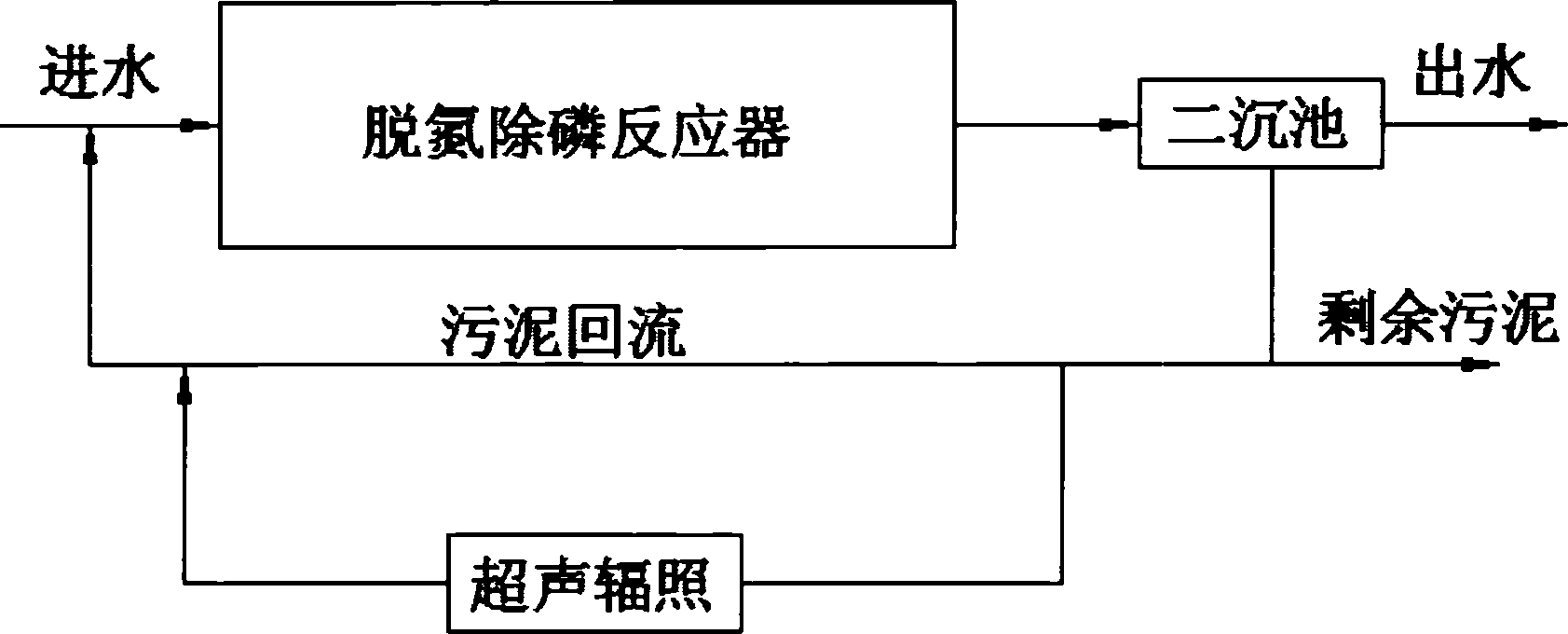

[0015] Such as figure 1 As shown, there is a secondary sedimentation tank after the continuous biological denitrification and phosphorus removal facility, and the bottom of the secondary sedimentation tank is equipped with an excess sludge discharge port and a return sludge pipeline, which can be used to treat part of the return sludge on the return sludge pipeline. Ultrasonic irradiation is performed on the sludge, and the irradiated sludge microorganisms are returned to the water inlet of the denitrification and phosphorus removal facility. In this embodiment, the sludge containing microorganisms is extracted from the return sludge pipeline of the secondary sedimentation tank after the continuous biological denitrification and phosphorus removal reactor according to 1-6 times per day, and the extracted sludge Microorganisms are subjected to ultrasonic irradiation treatment for 5-30 minutes at an ultrasonic frequency of 20-40 kHz, and the amount of sludge extracted each time ...

Embodiment 2

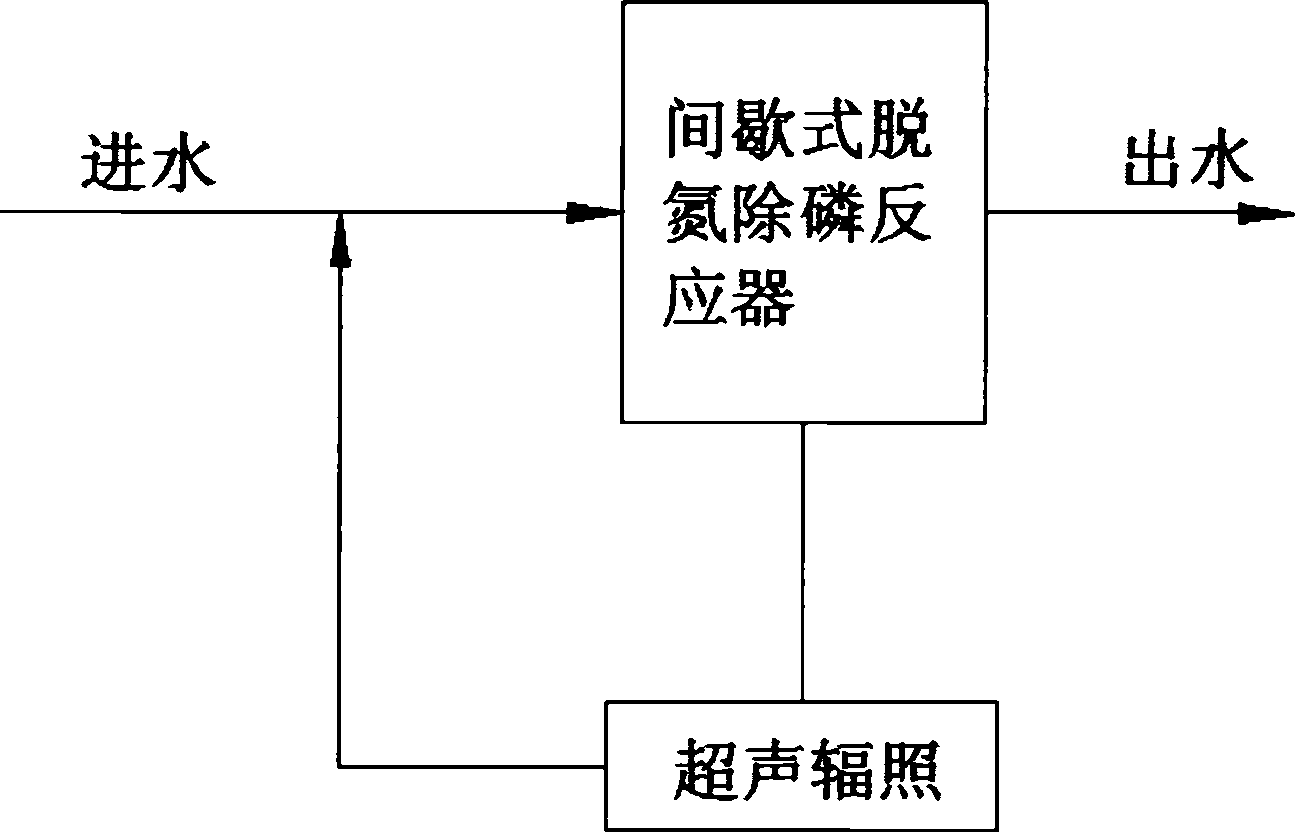

[0017] Such as figure 2 As shown, when a batch-type denitrification and phosphorus removal reactor is used, 5%-25% of the mud-water mixture can be directly taken, concentrated by precipitation, and then ultrasonically treated for 5-30 minutes, and then returned to the reactor water inlet. Or for ultrasonication in the idle stage, the concentrated sludge at the bottom of the reactor can be directly taken for ultrasonication. The frequency of ultrasound used is 20-40kHz, and ultrasound is performed 1-6 times a day.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com