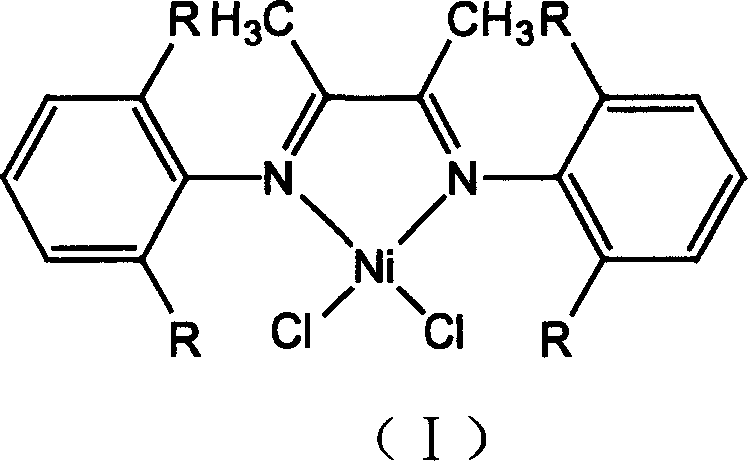

Method for preparing beta-pinene polymer using alpha-diimine nickel complex as catalyst

A technology for nickel complexes and polymers is applied in the field of preparing high-molecular-weight beta-pinene polymers, and can solve the problems of complex post-processing process, low molecular weight of poly-beta-pinene, and large dosage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

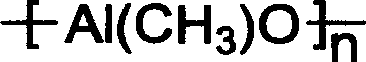

[0018] Example 1: β-pinene polymerization catalyzed by α-diimine nickel complex 1 / MAO system

[0019] Firstly, the a-diimine nickel complex 1 and MAO were made into concentrations of 3.46×10 -3 mol / L and 80.4g / L toluene solution, wherein a-diimine nickel complex 1 needs to add a small amount of dichloroethane (20%) to help dissolve. Then, 1.0 mL of the above-mentioned α-diimine nickel complex 1 solution, 1.0 mL of MAO solution, 8.0 mL of toluene, and 5.0 mL of β-pinene were sequentially added into the 50 mL ground-mouth reaction vial with a syringe. Seal the reaction bottle and react at 40°C for 1.5 h, then pour the reaction solution into 400 mL of 5% methanolic hydrochloric acid solution to obtain a white precipitate. The monomer conversion rate is 90.5%, and the activity of the catalyst system is 1.14×10 6 [g(polymer) / mol(N i )]. The number average molecular weight of the β-pinene polymer measured by GPC was 4200, and the PDI=1.73.

Embodiment 2

[0020] Example 2: β-pinene polymerization catalyzed by a-diimine nickel complex 2 / MAO system

[0021] The same polymerization method as in Example 1, but with a-diimine nickel complex 2 instead of a-diimine nickel complex 1. Reaction at 40°C for 1.5h, conversion rate 90.7%, catalyst system activity is 1.14×10 6 [g(polymer) / mol(N i )]. The number average molecular weight of the β-pinene polymer measured by GPC was 4400, and the PDI=1.92.

Embodiment 3

[0022] Example 3: β-pinene polymerization catalyzed by a-diimine nickel complex 3 / MAO system

[0023] The same polymerization method as in Example 1 was used, but the feeding was changed to 0.5 mL of α-diimine nickel complex 3 solution, 0.5 mL of MAO solution, 9.0 mL of toluene, and 5.0 mL of β-pinene. Reacted at 40°C for 1.5h, the conversion rate was 94.1%, and the activity of the catalyst system was 1.59×10 6 [g(polymer) / mol(N i )]. The number-average molecular weight of the β-pinene polymer measured by GPC was 7450, and the PDI=2.02.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com