Method for integrative consolidation of soft soil groundsill by double vacuum self-load combined prepress and dynamic squeeze

A technology that combines preloading and soft soil foundation. It is used in soil protection, infrastructure engineering, construction, etc. It can solve the problem of low bearing capacity of soft soil, low consolidation index, and inability to obtain precipitation preloading for the mud seal layer. problems, to achieve the effect of broadening the scope of application and improving the consolidation index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

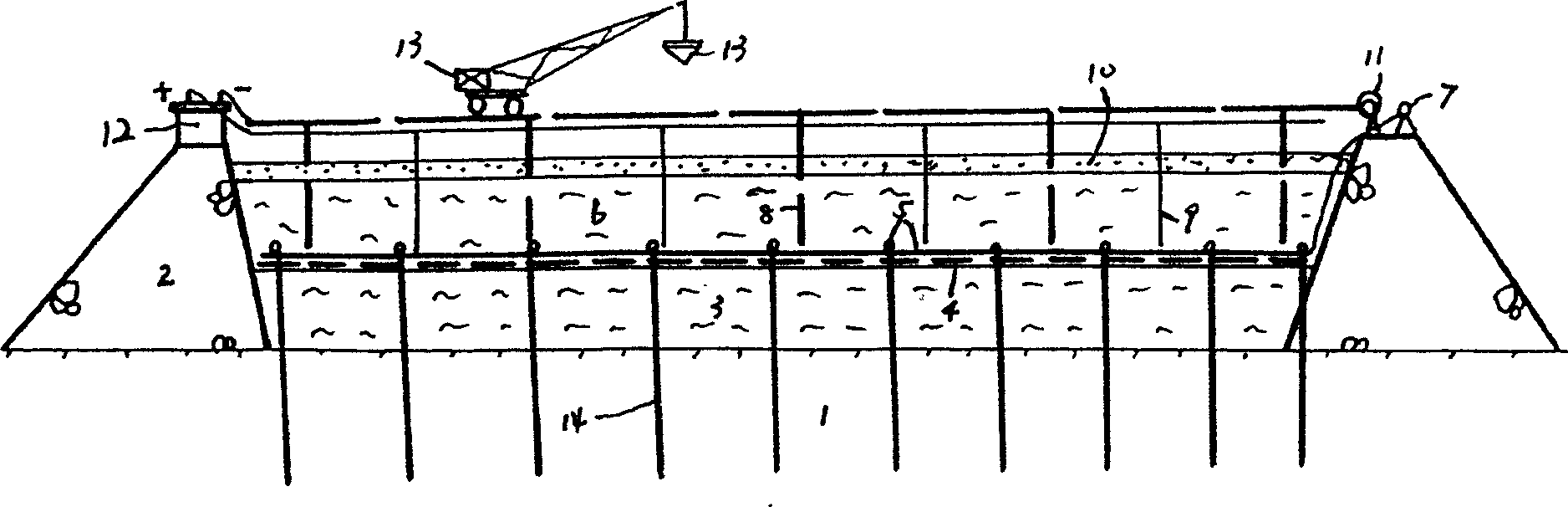

[0045] The invention relates to a method for comprehensively strengthening soft soil foundation with double vacuum self-loading combined with preloading and dynamic compaction. The method includes the following process steps:

[0046] a), low vacuum self-loading joint preloading

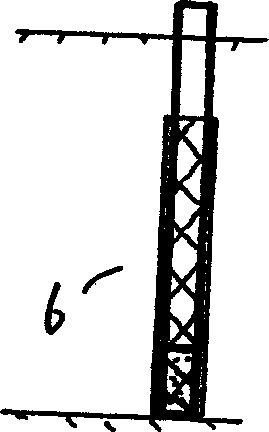

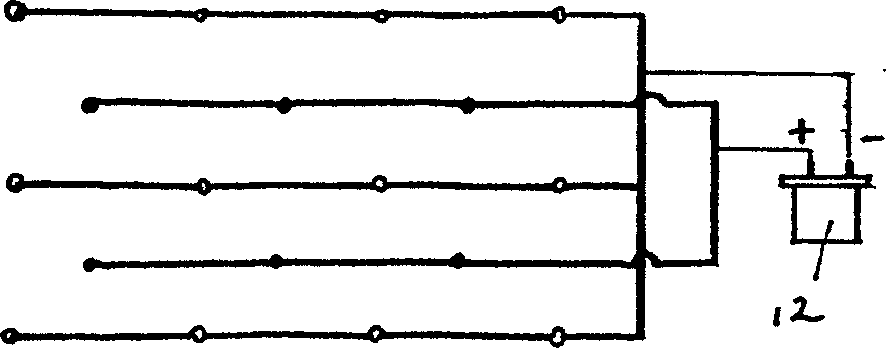

[0047] see figure 1 , build a cofferdam 2 around the treated site, blow mud 3 into the cofferdam to a certain elevation, spread a geotextile and a bamboo board 4 on the blown-fill mud surface, vertically insert a plastic drainage board 14, Lay vacuum horizontal pipe network 5, install vacuum preloading system 7 and blow thick mud seal layer 6 as self-loaded preload, mud seal layer thickness is 2.0-6.0m, vacuum preload system is evacuated, low-level vacuum self-load combined preload start.

[0048] When the soft soil under the mud seal layer reaches the design consolidation degree under the joint action of vacuum negative pressure and mud seal layer self-loading preload, and the mud seal layer also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com