Chuck workbench moving arrangement

A technology of chuck table and moving mechanism, which is applied in the direction of metal processing machinery parts, manufacturing tools, conveyor objects, etc., and can solve problems that may not be able to meet the high-precision movement of chuck table

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Next, the preferred embodiment of the chuck table moving mechanism constructed according to the present invention will be described in more detail with reference to the accompanying drawings.

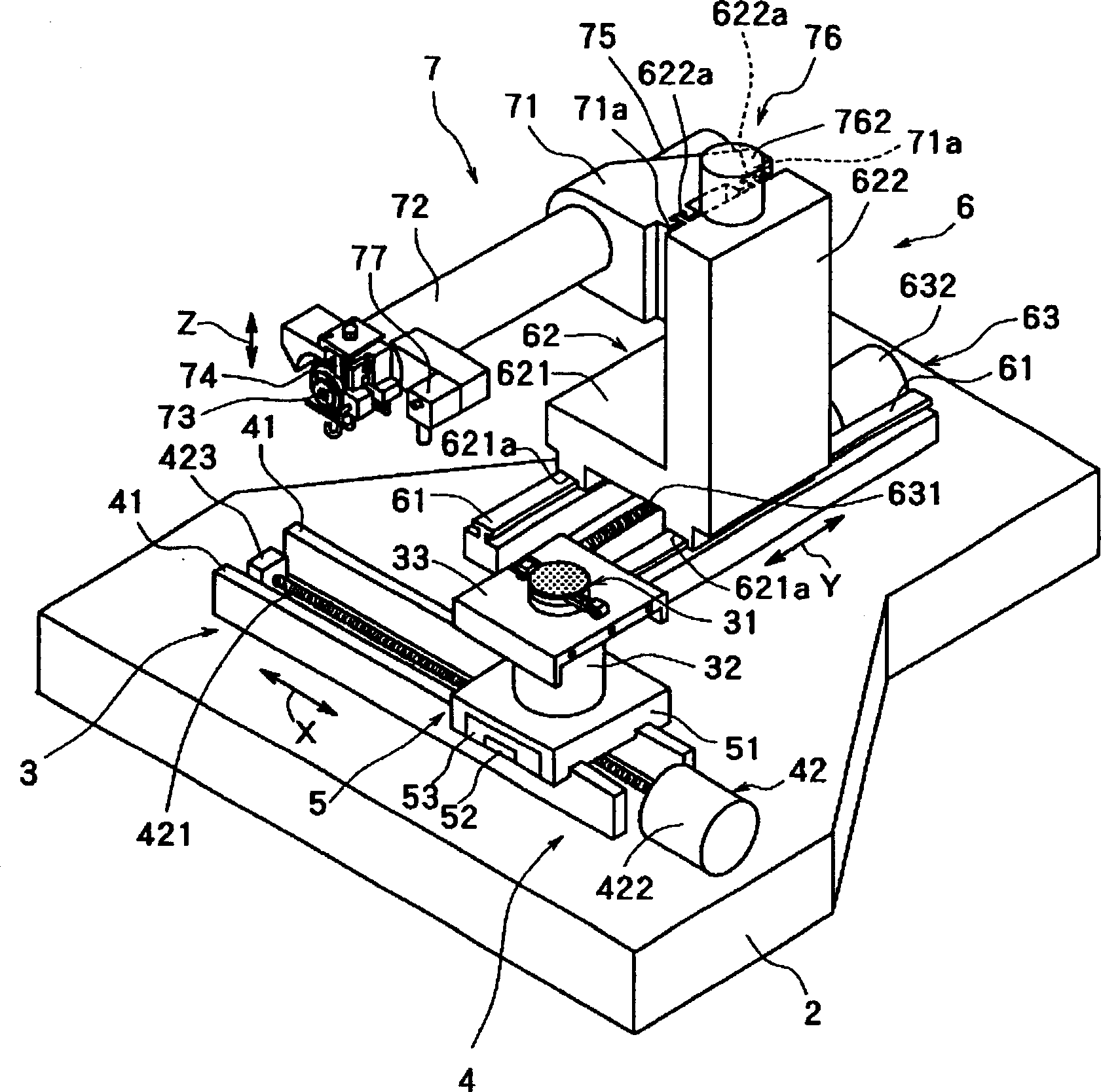

[0021] figure 1 It is a perspective view showing main parts of a cutting device equipped with a chuck table moving mechanism according to the present invention.

[0022] figure 1 The cutting device shown is equipped with: a stationary base 2; a chuck table mechanism 3 which is movably arranged on the stationary base 2 in the machining feed direction indicated by the arrow X to support the workpiece; In the indexing feed direction represented by arrow Y (the direction perpendicular to the processing feed direction represented by arrow X), the spindle supporting mechanism 6 that is movably arranged on the stationary base 2; A spindle assembly 7 serving as a cutting mechanism is movably arranged on the spindle support mechanism 6 in the tool depth feeding direction.

[0023] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com