Flexible circuit substrate manufacturing method

A technology for flexible circuit substrates and manufacturing methods, which is applied in the fields of printed circuit manufacturing, printed circuit, circuit inspection/identification, etc., and can solve problems such as product reliability, insufficient integration efficiency, and poor productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings, through which the purpose, features, and advantages of the present invention can be better understood.

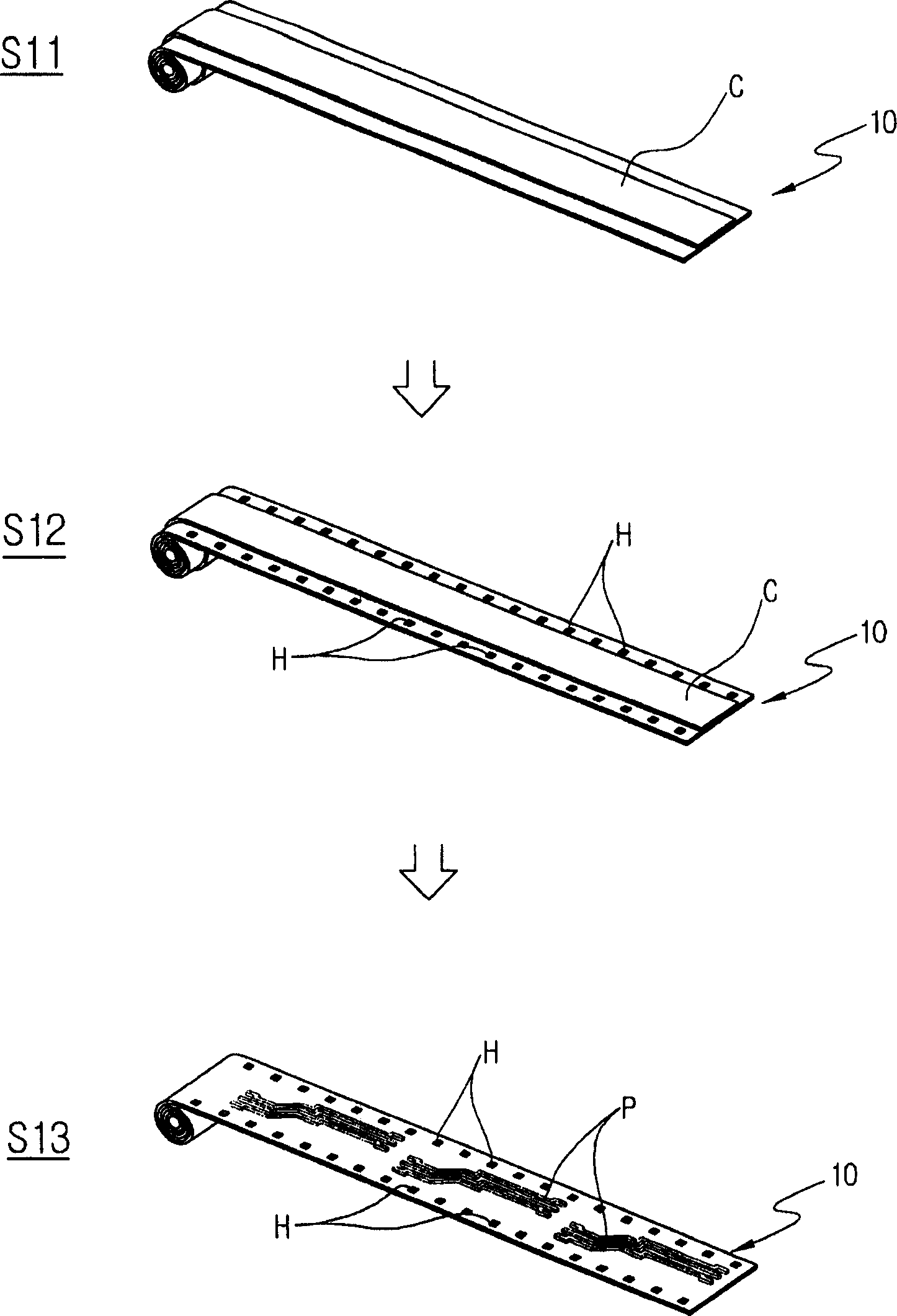

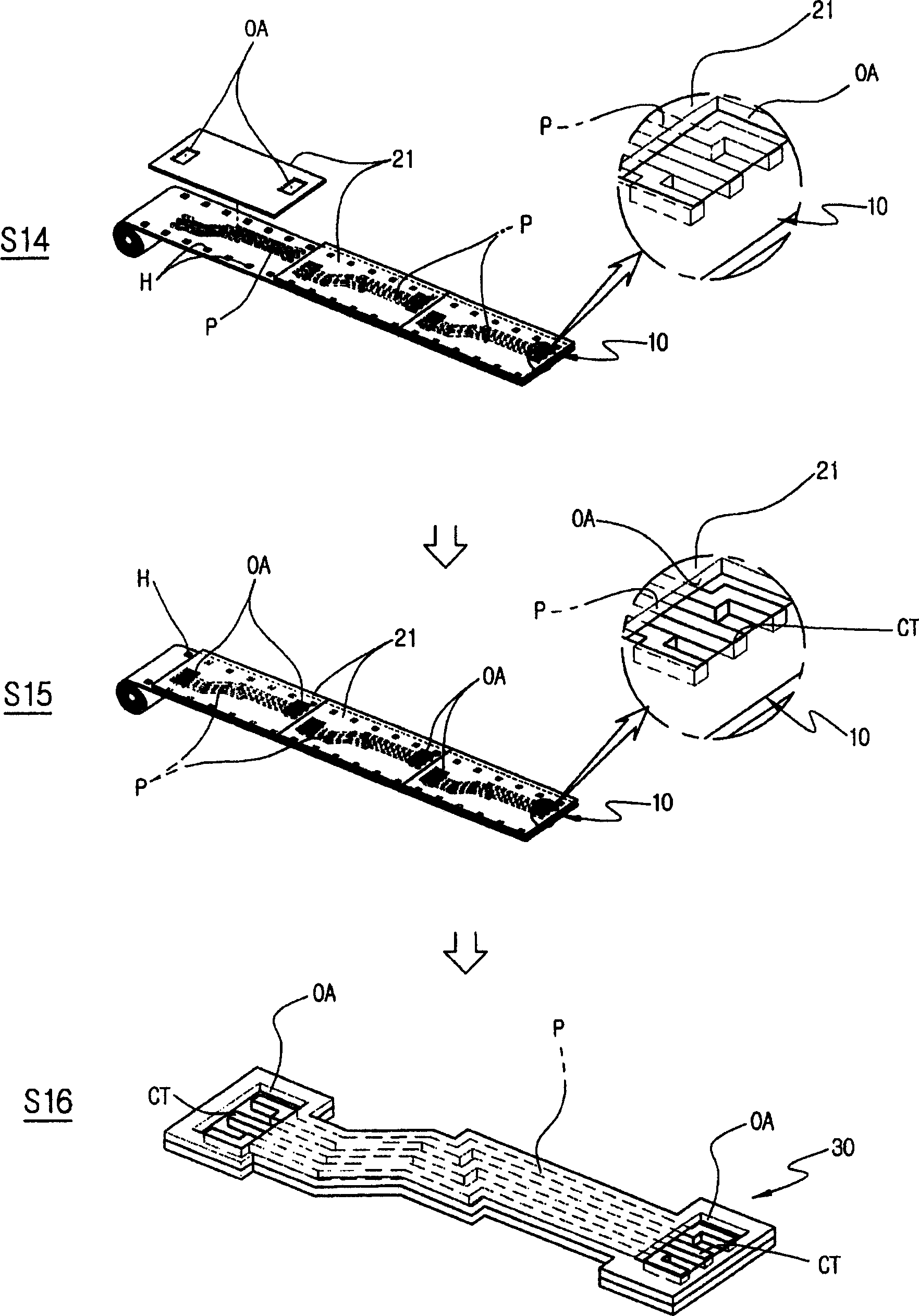

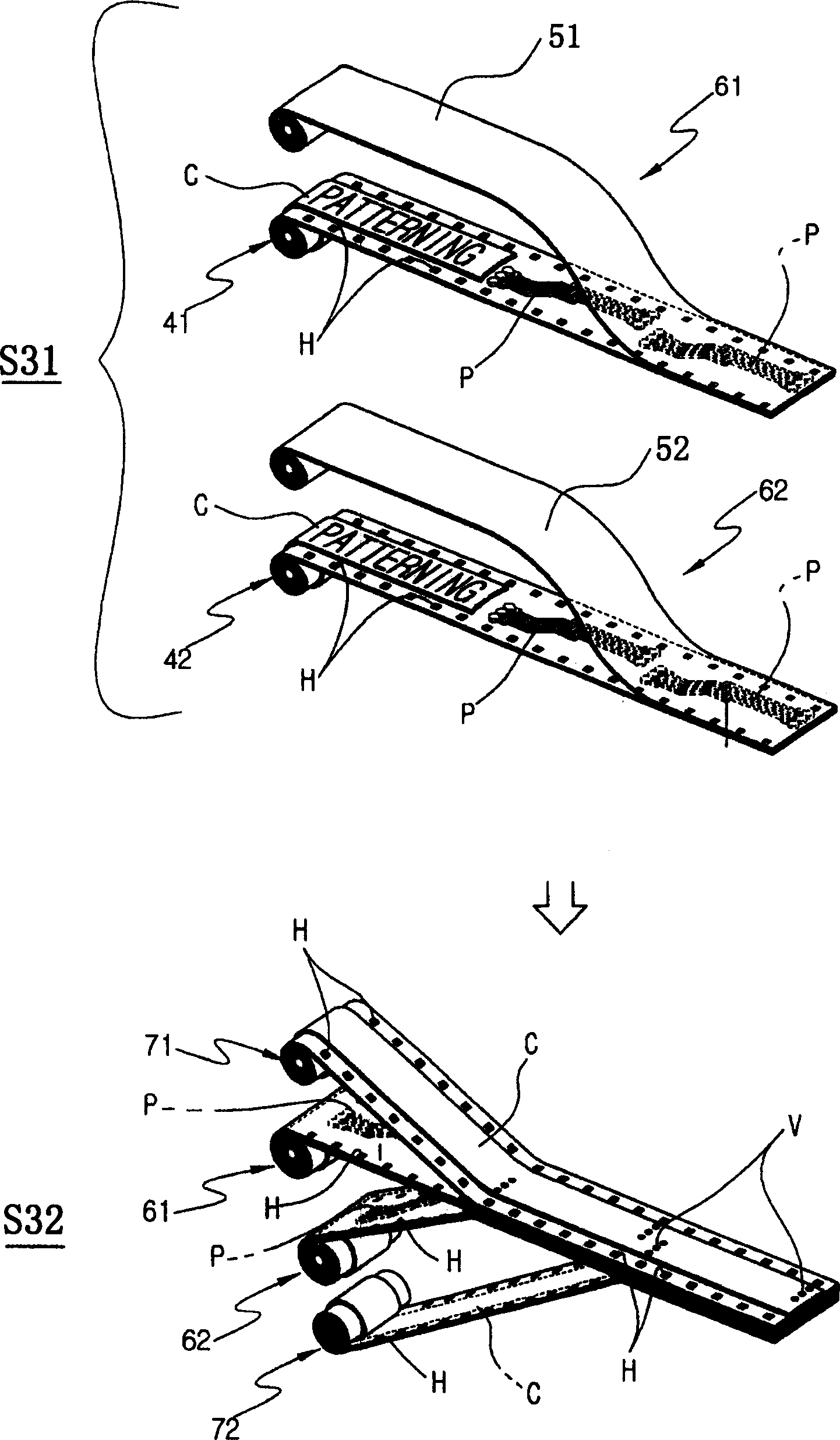

[0017] Figure 1a and Figure 1b It is a process drawing which shows the manufacturing method of the flexible circuit board which concerns on the 1st Embodiment of this invention.

[0018] like Figure 1a and Figure 1b As shown, the manufacturing method of the flexible circuit substrate of the present invention provides that copper foil (Cu thin film) C is vapor-deposited on PI film (Poly Imide Film polyimide film) or polyester with reel to reel mode (Reel to Reel). A copper clad C-laminate film (CCL; CopperClad Laminate) 10 on a Polyester Film (S11), and a guide hole H for position sensing is provided at the edge of the copper clad C-laminate film 10 in the longitudinal direction (S12) .

[0019] The guide hole H for position sensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com