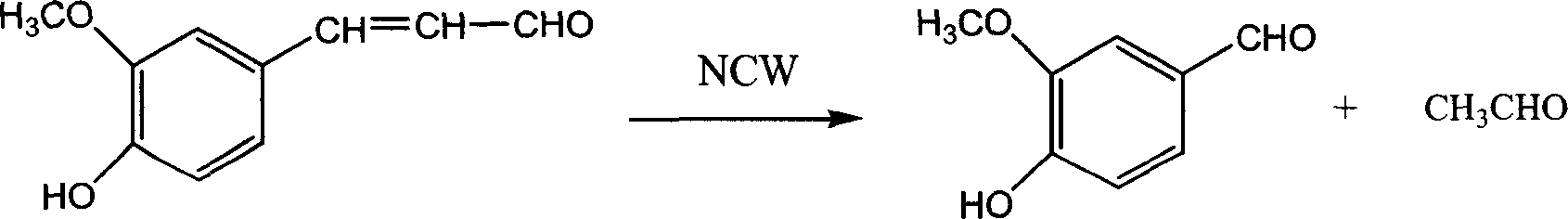

No-catalyst ferulaldhyde hydrodizing process to prepare vanillin in near critical water medium

A technology of near-critical water and catalytic hydrolysis, which is applied in the direction of alkyne addition to prepare oxygenates, organic chemistry, etc., can solve the problems of raw material source limitation, high product cost, and no relevant reports of industrialization, etc., and achieve simple reaction process, The effect of good quality and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

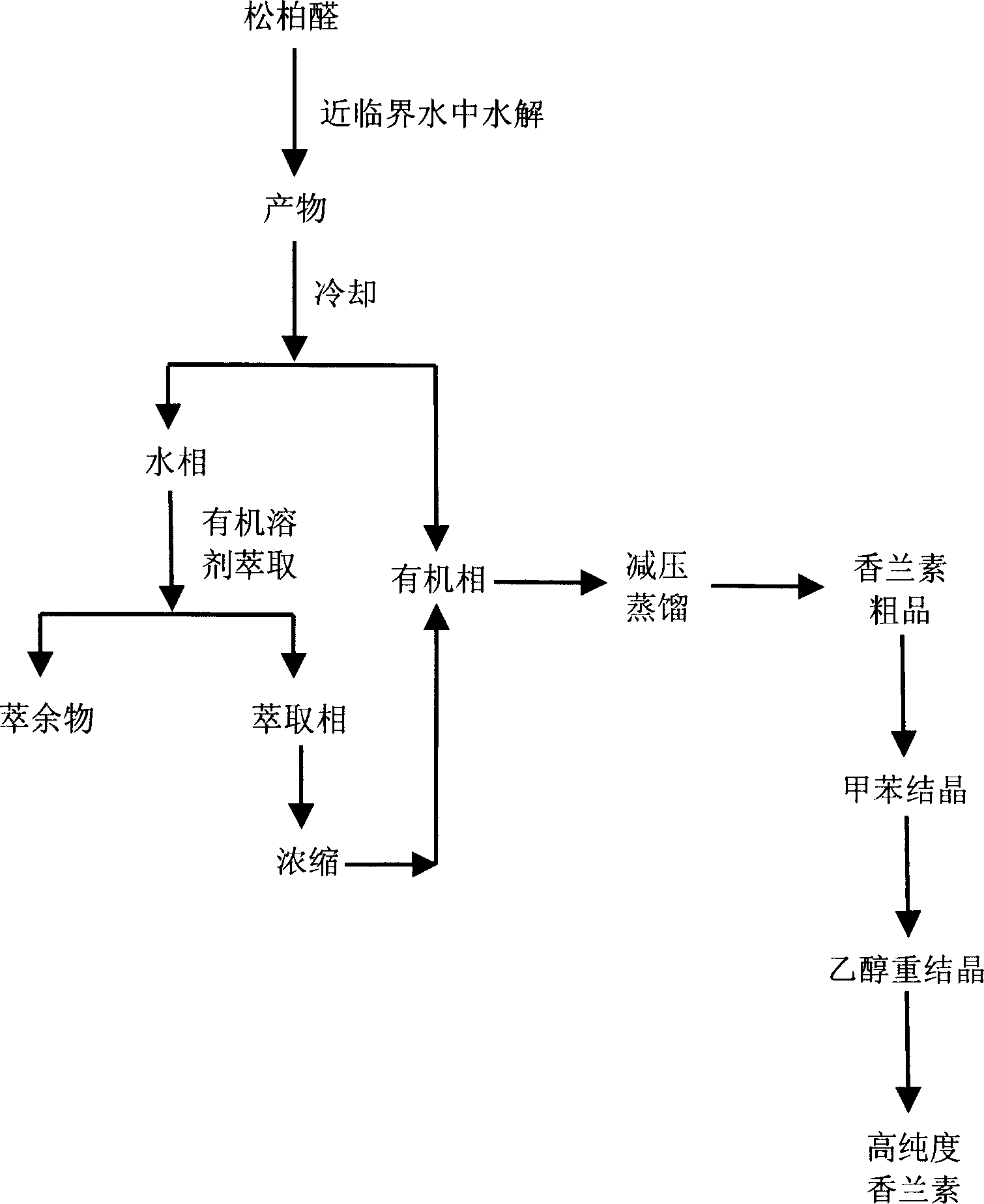

[0024] Add 200g deionized water and 200g coniferaldehyde into a 500mL intermittent high-pressure reactor, start stirring, heat up to boiling under normal pressure, open the exhaust valve for 2 minutes, and use water vapor to remove the air in the kettle; continue to heat up to 200°C for 8 hours for hydrolysis The hydrolyzate is divided into an aqueous phase and an organic phase after cooling, the aqueous phase is extracted with chloroform, and the extraction phase is evaporated to remove chloroform and then merged with the organic phase; the combined organic phase is distilled under reduced pressure to obtain crude vanillin, and then crystallized with toluene, Ethanol recrystallization yielded 32.2 g of the product vanillin.

Embodiment 2

[0026] Add 260g deionized water and 130g coniferaldehyde into a 500mL intermittent high-pressure reactor, start stirring, heat up to boiling under normal pressure, open the exhaust valve for 3min, and use water vapor to remove the air in the kettle; continue to heat up to 240°C for 4h for hydrolysis The hydrolyzate is divided into an aqueous phase and an organic phase after cooling, and the aqueous phase is extracted with dichloromethane, and the extracted phase is evaporated to remove the dichloromethane and merged with the organic phase; the combined organic phase is distilled under reduced pressure to obtain the crude vanillin, and then After crystallization from toluene and recrystallization from ethanol, 64.6 g of vanillin was obtained.

Embodiment 3

[0028] Add 300g deionized water and 100g coniferaldehyde into a 500mL intermittent high-pressure reactor, start stirring, heat up to boiling under normal pressure, open the exhaust valve for 4min, and use water vapor to remove the air in the kettle; continue to heat up to 260°C for 3h for hydrolysis The hydrolyzate is divided into an aqueous phase and an organic phase after cooling, and the aqueous phase is extracted with n-butanol, and the extracted phase is evaporated to remove n-butanol and merged with the organic phase; the combined organic phase is distilled under reduced pressure to obtain the crude vanillin, and then After crystallization from toluene and recrystallization from ethanol, 75.4 g of vanillin was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com