Display device panel structure and producing method thereof

A technology for a display device and a manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve the problems of complicated processes, increased time and money costs, and increased product defect rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

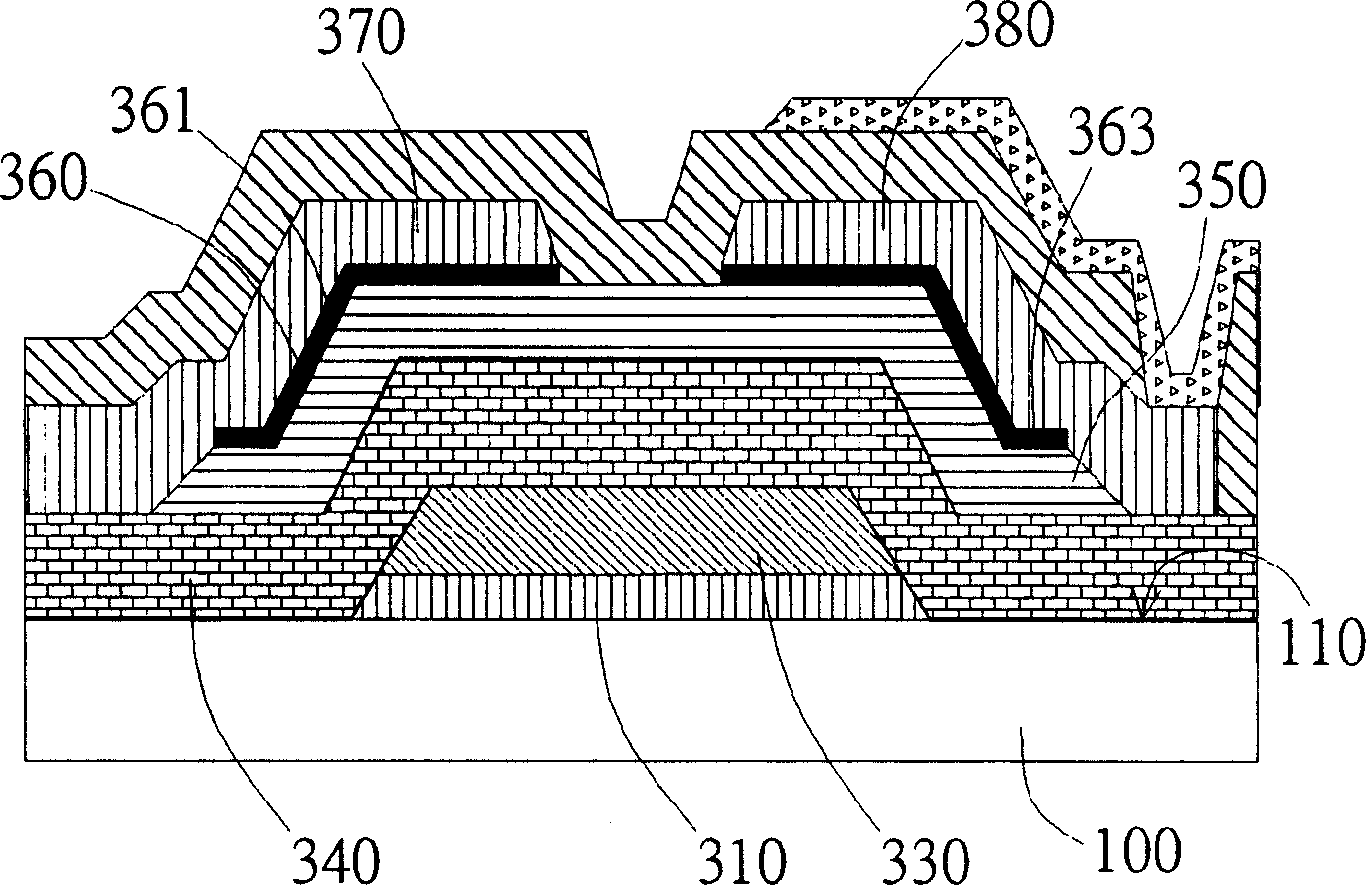

[0039] The invention provides a panel structure of a display device and a manufacturing method thereof. In a preferred embodiment, the panel structure of the display device includes a display panel of a liquid crystal display device; however, in different embodiments, the panel structure of a display device may also include a panel structure of an OLED display device or other display devices.

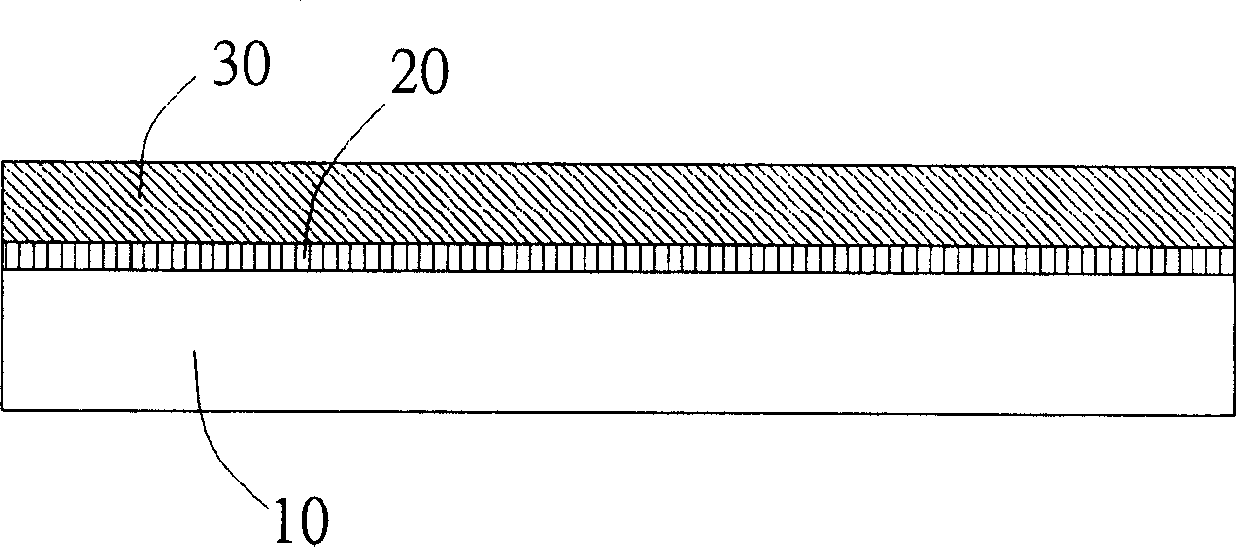

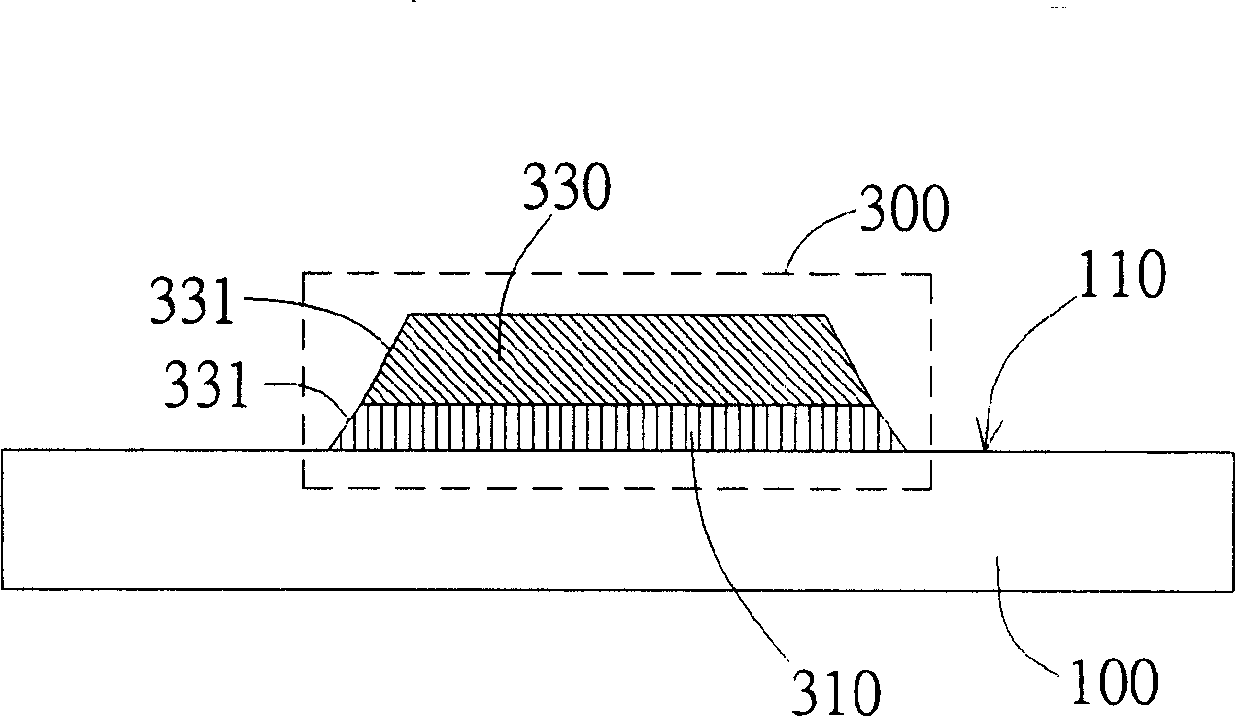

[0040] figure 2Shown is an embodiment of the panel structure of the display device of the present invention. In this embodiment, the panel structure of the display device mainly includes a substrate 100 and a circuit element 300 . The substrate 100 is preferably a glass substrate formed of glass; however, in different embodiments, the substrate 100 may also be a polymer substrate formed of a polymer, such as a plastic substrate. In addition, the circuit element 300 preferably includes a transistor, such as an amorphous silicon thin-film transistor (a-Si Thin-Film-Transistor, a-Si TFT...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com