Bearing device for turbocharger

A technology of turbocharger and bearing device, which is applied in bearing assembly, lubrication of turbine/propulsion device, bearing of rotary motion, etc., can solve the problems of increased processing cost, trouble in production, insufficient rotation and fixation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

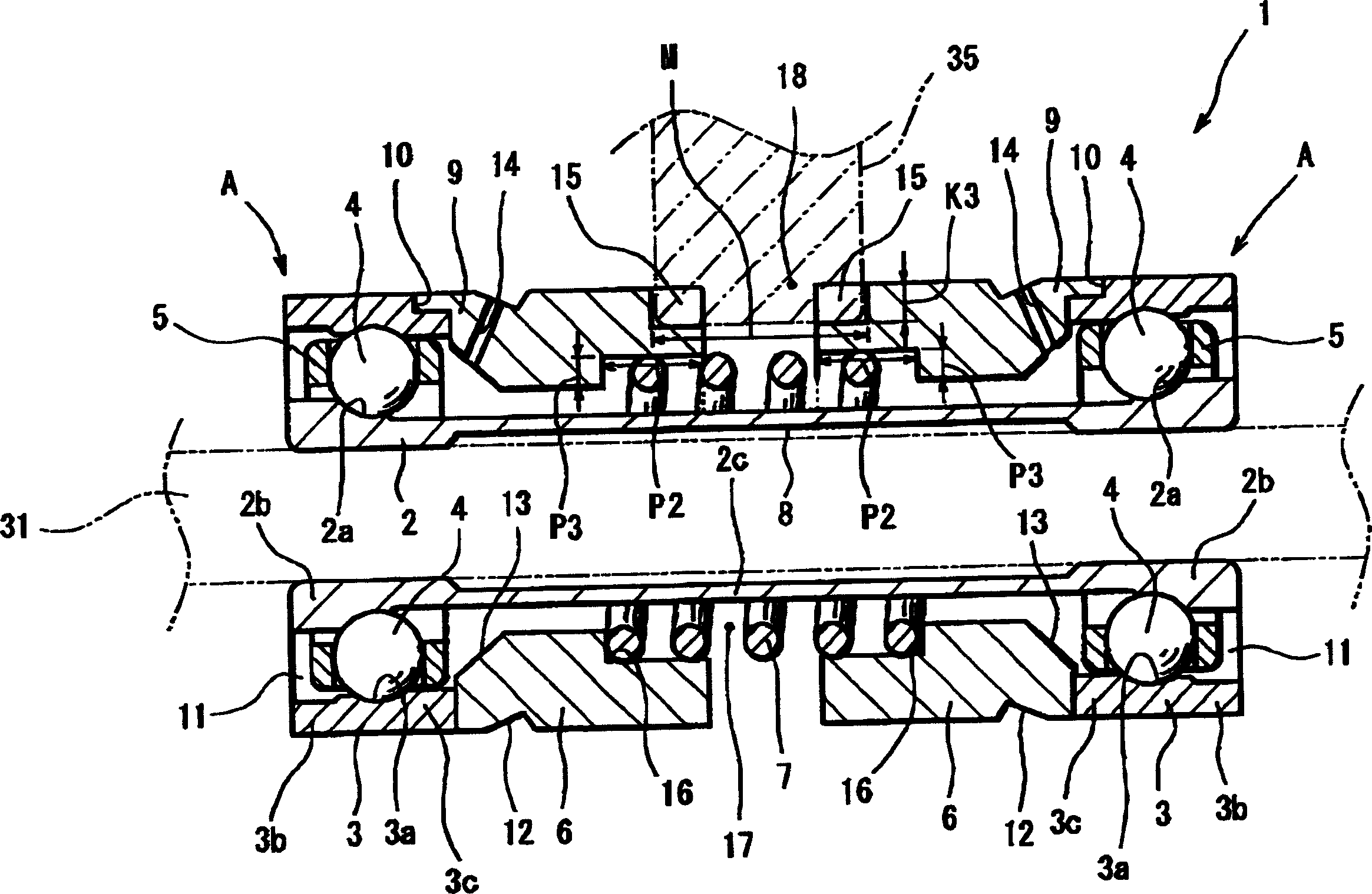

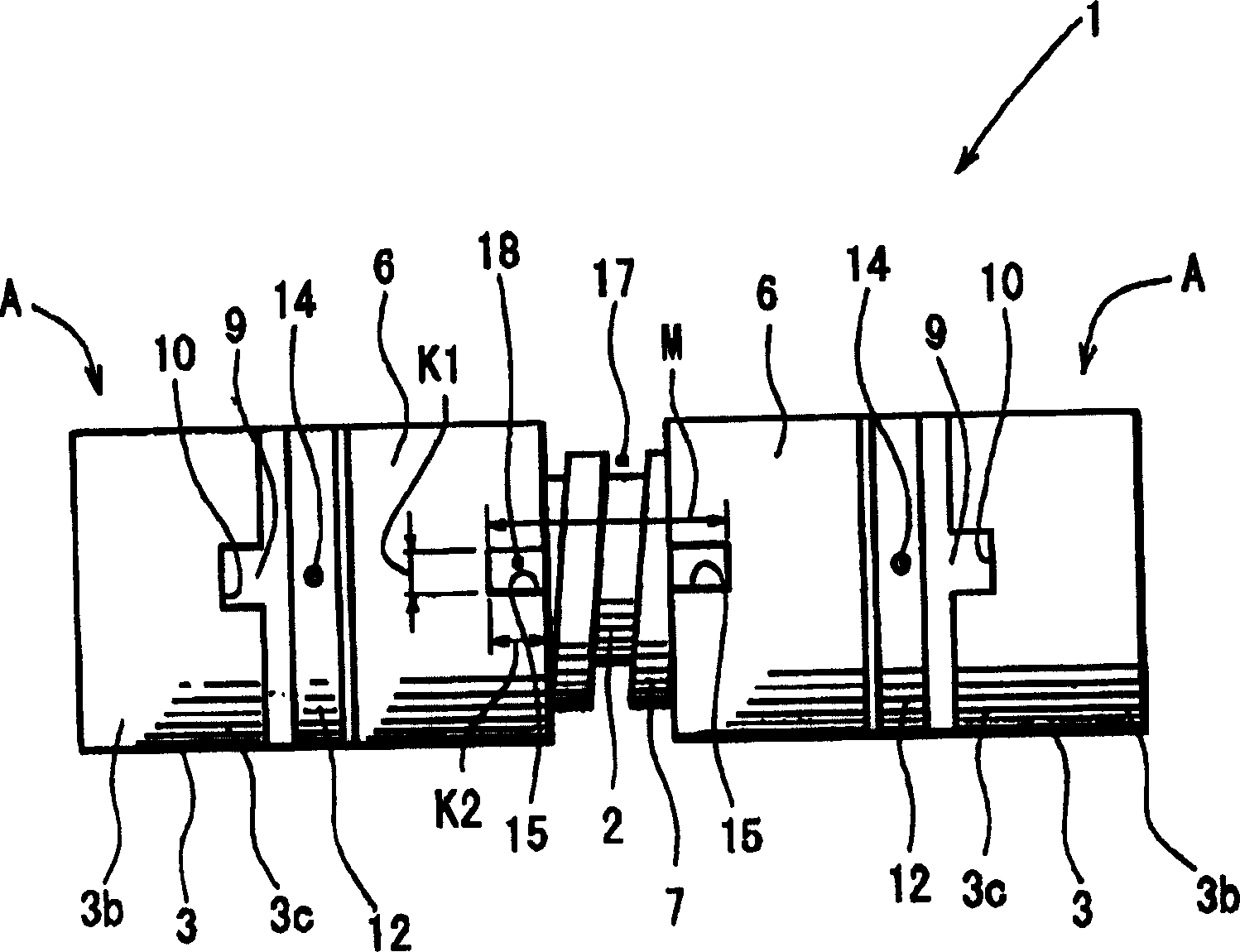

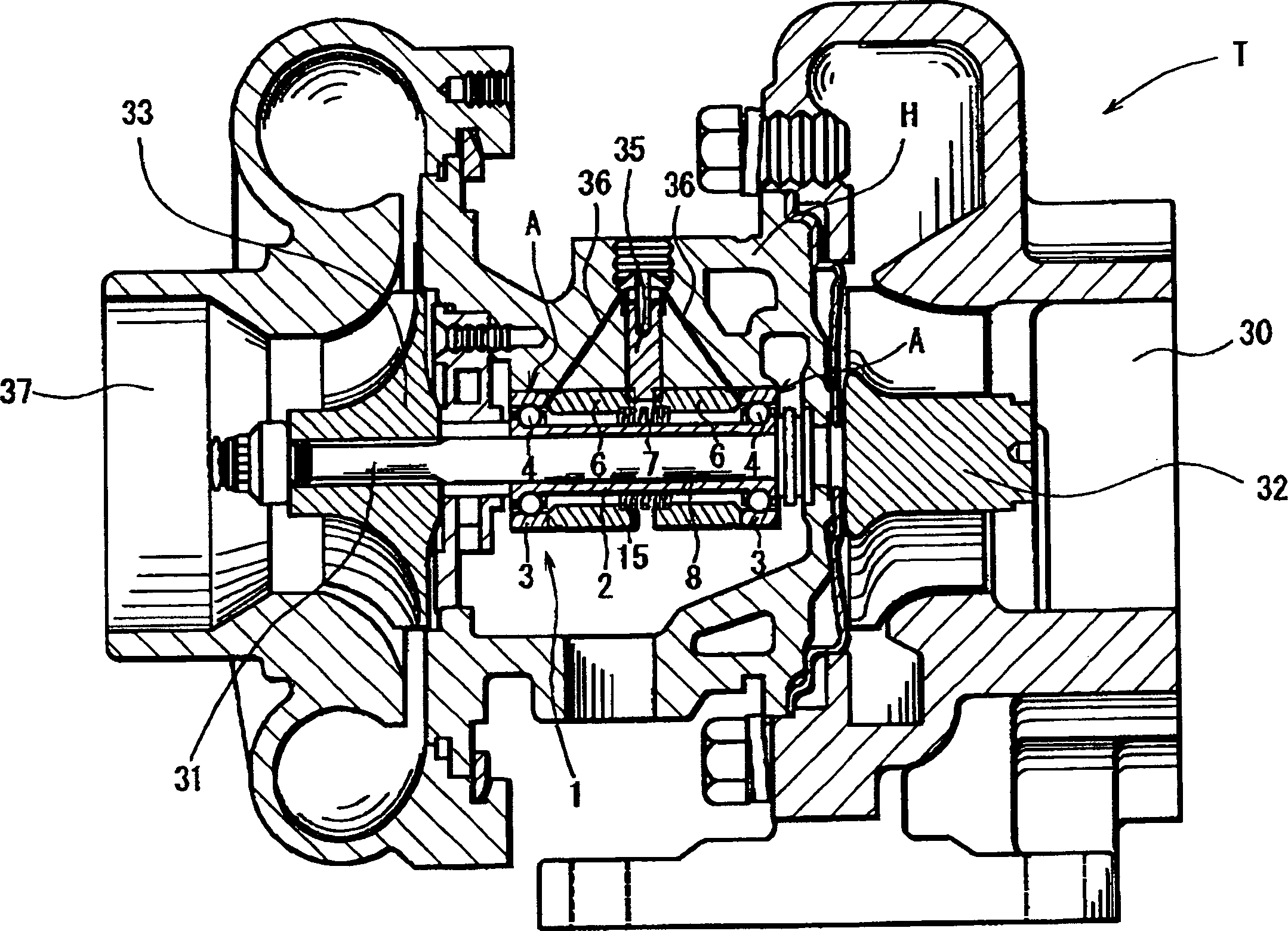

[0017] figure 1 It is a sectional view showing the first embodiment of the turbocharger bearing device 1 according to the present invention. figure 2 is its floor plan. image 3 A schematic diagram showing a turbocharger T incorporating the turbocharger bearing device 1 is shown. The turbocharger T is fixed on one end of the rotating shaft 31 ( image 3 The turbine 32 on the right side) rotates. The rotation of the rotating shaft 31 is transmitted to the other end fixed on the rotating shaft 31 ( image 3 The impeller 33 on the left side of the left side), so that the air sucked in the suction line 37 is compressed by the impeller 33 . As a result, the compressed air is sent into the cylinder chamber of the engine together with fuel such as gasoline and light oil. The rotary shaft 31 of such a turbocharger T rotates at a high speed of tens of thousands to hundred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com