Electric coutrol chamber cooling system for electric oven

A cooling system and electric control room technology, applied in food ovens, baking, household stoves/stoves, etc., can solve problems such as damage to high-voltage capacitors 52, achieve effective cooling, prevent misoperation, and smooth air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

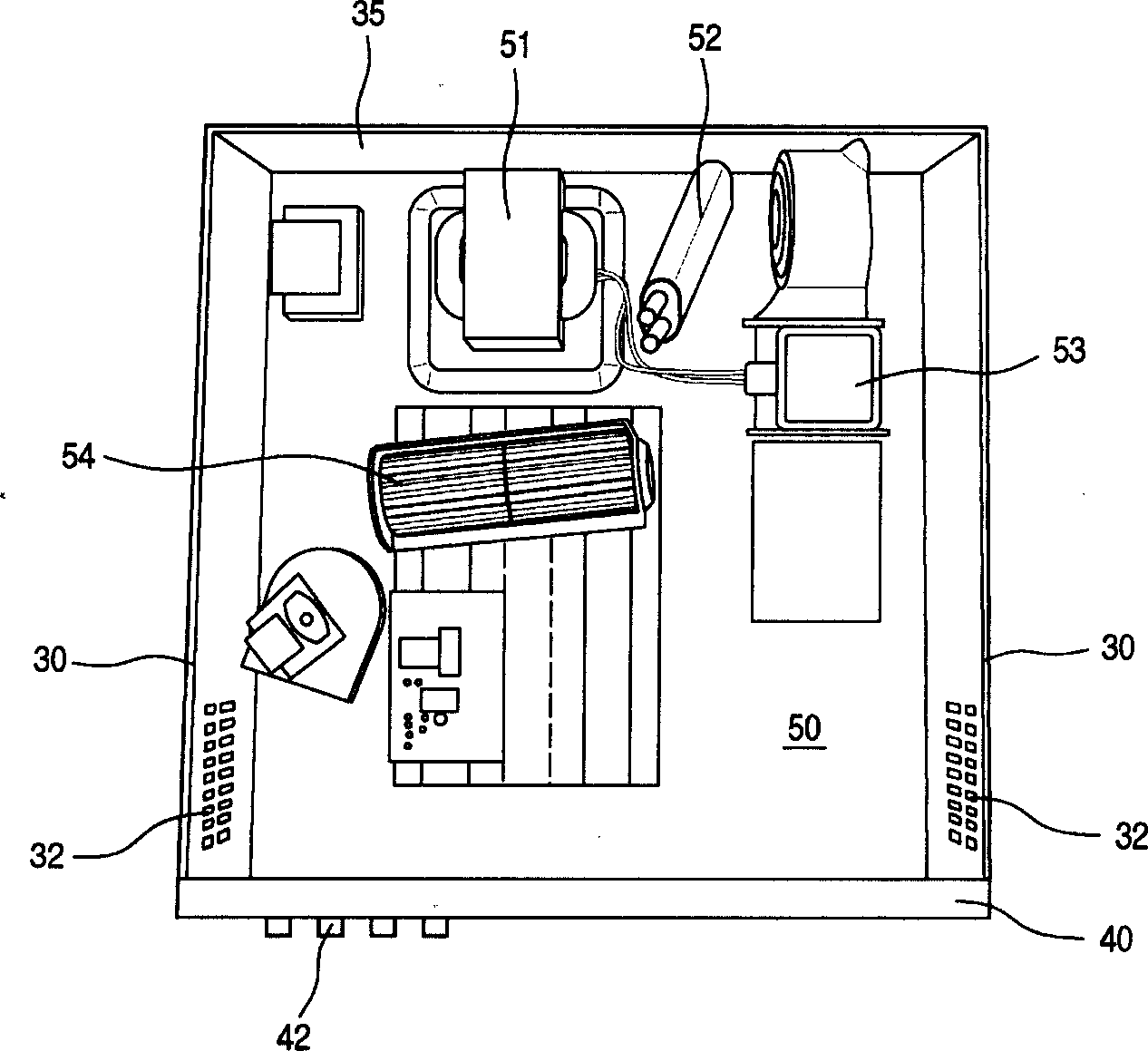

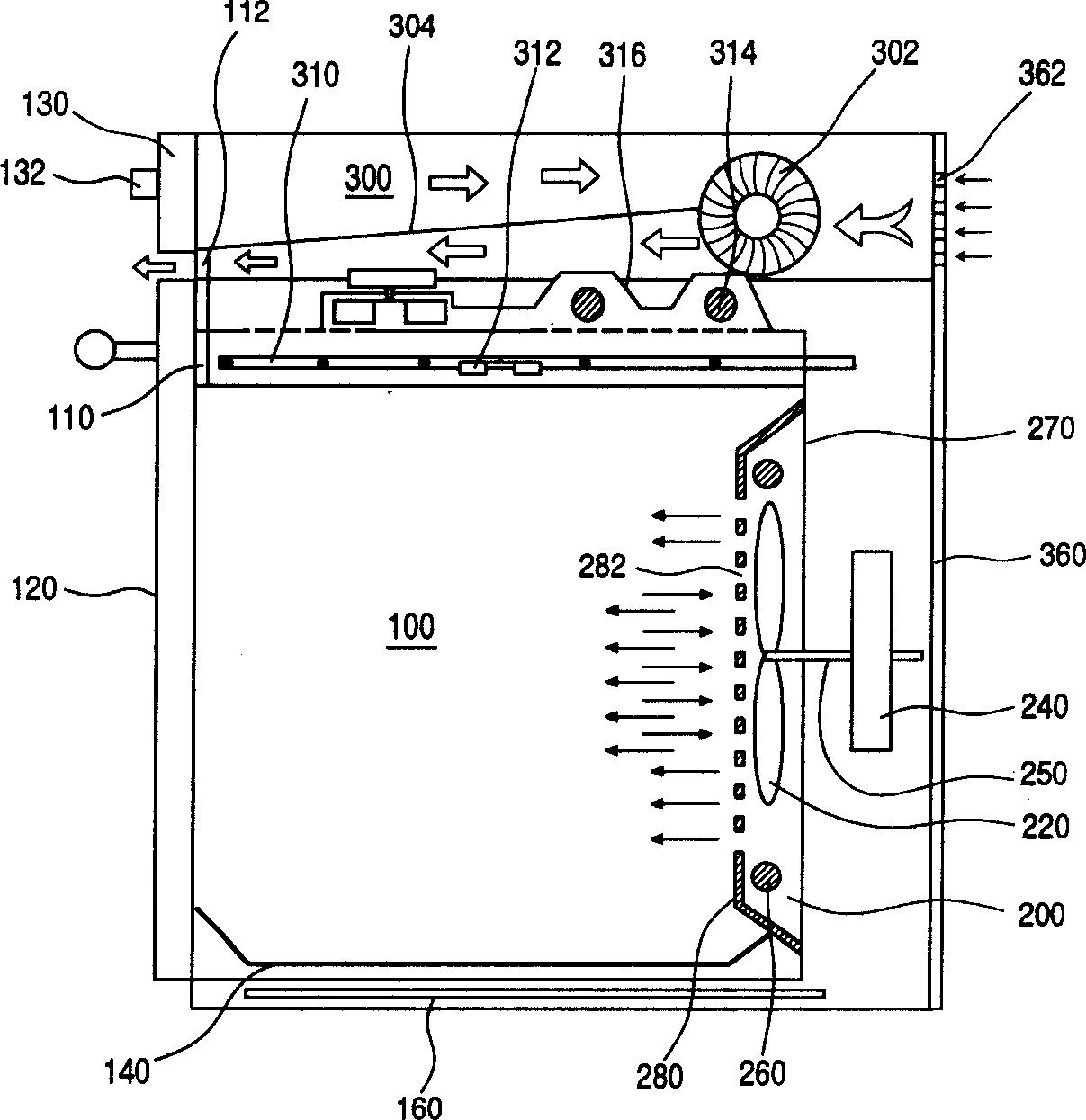

[0045] image 3 It is a side view structural schematic diagram of the present invention; Figure 4 It is a plan view of the structure of the present invention.

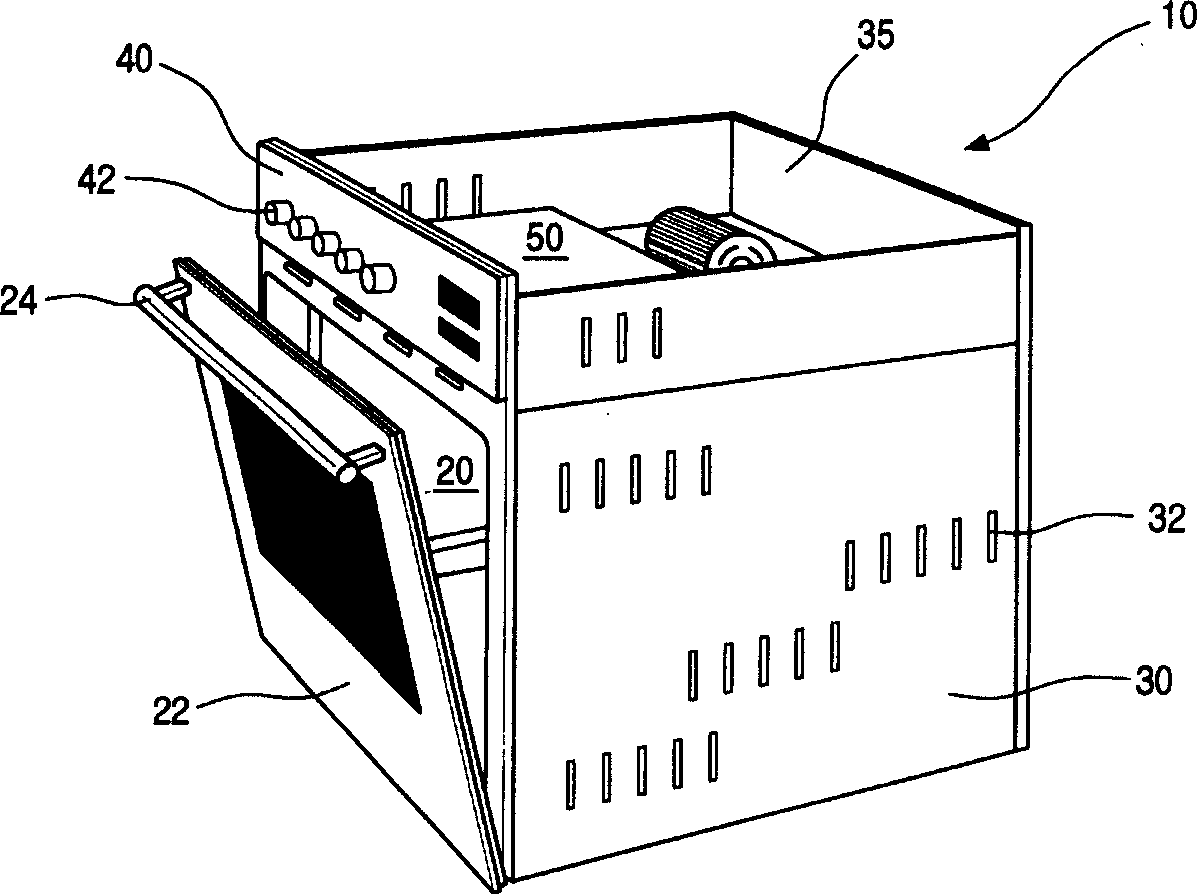

[0046] As shown in the figure, a cooking chamber 100 for cooking food is provided inside the electric oven adopting the cooling system of the electronic control room of the electric oven of the present invention.

[0047] The front end of the cooking chamber 100 is provided with a front panel 110 forming a front appearance. The front panel 110 is formed along the edge of the front end of the cooking chamber 100 . The upper end of the front panel 110 is provided with an exhaust port 112 .

[0048] There are a plurality of exhaust ports 112 penetrating front and rear. Furthermore, the exhaust port 112 serves as an outlet through which air inside the electronic control room 300 is discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com