Easy-split stretched film, easy-split laminated film, easy-split bag, and manufacturing method for easy-split stretched film

An easy-to-tear, laminated film technology, used in chemical instruments and methods, layered products, flexible coverings, etc. The effect of excellent, excellent straight-line cutting properties, and excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0052] The easy-to-tear stretch film of this embodiment contains Ny6 and MXD6 as raw materials, and the raw materials include: a virgin material containing 60 to 85 parts by mass of Ny6 and 15 to 40 parts by mass of MXD6, and formed by melting and kneading Ny6 and MXD6 The melting point of MXD6 in the thermal history is 233-238° C., and the content of the thermal history is 5-40% by mass based on the total amount of raw materials. Here, the chemical formula of Ny6 is shown in Formula 3, and the chemical formula of MXD6 is shown in Formula 4.

[0053] [Formula 3]

[0054] H-〔NH-(CH 2 ) 5 -CO〕 n -OH

[0055] [Formula 4]

[0056]

[0057] From the point of view of linear cutability and impact strength of the film after film formation, the blending ratio of Ny6 and MXD6 must be 60-85 parts by mass of Ny6 and 15-40 parts by mass of MXD6 in the virgin material. When the amount of MXD6 is less than 15 parts by mass in the virgin material, the linear cutting property will det...

no. 2 Embodiment approach

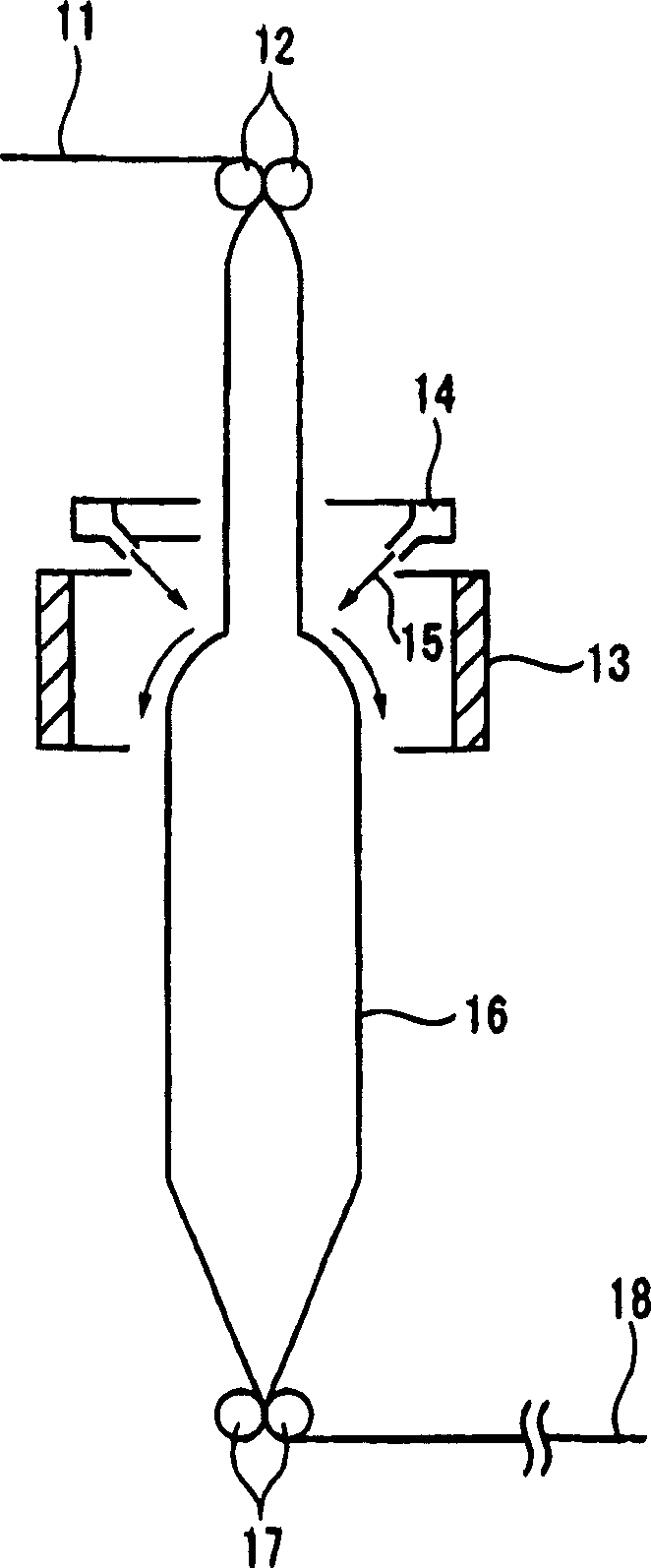

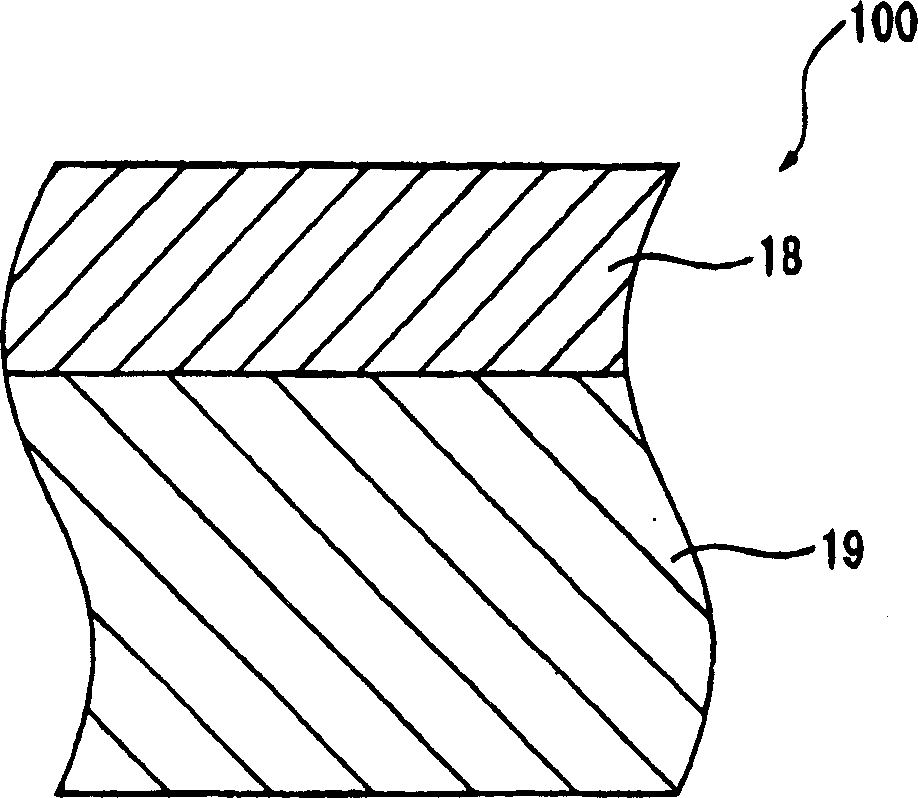

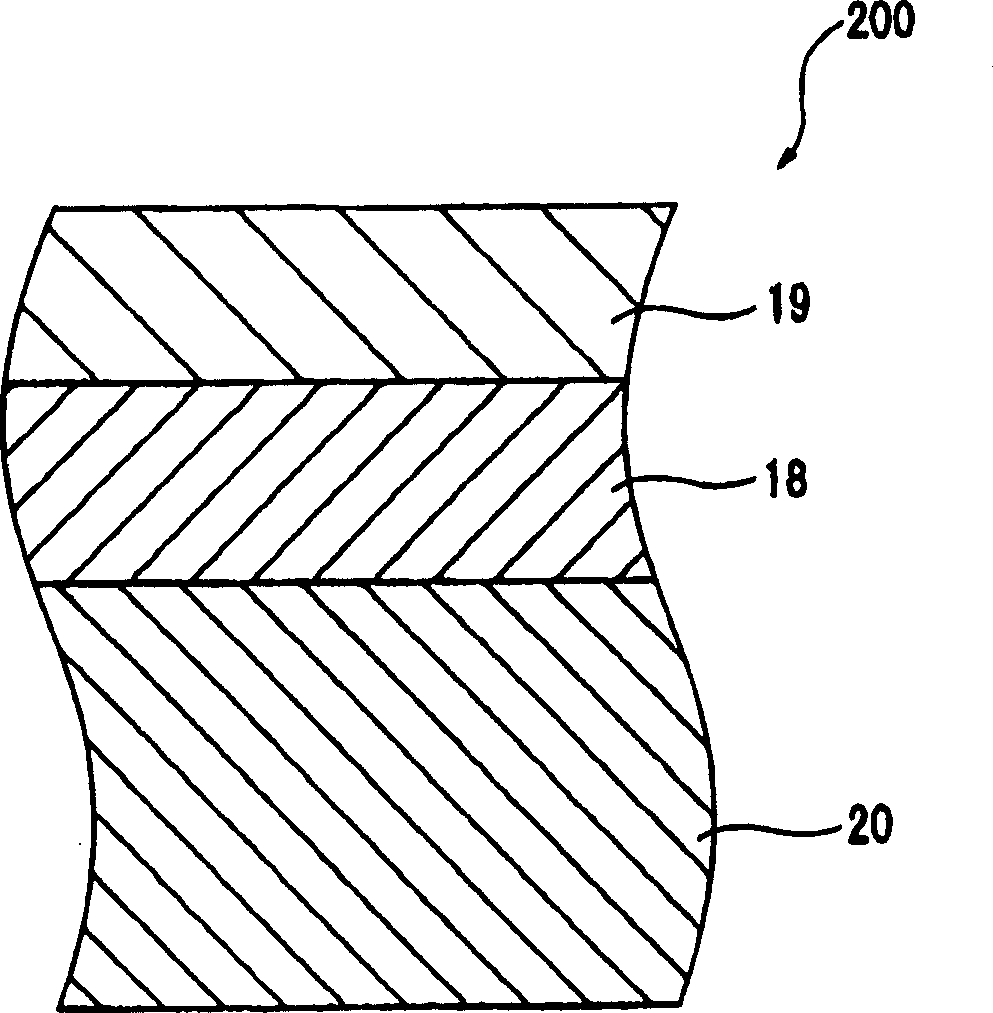

[0070] The easily tearable laminated film of the present invention contains at least one layer of the easily tearable stretched film, and may contain several layers such as two layers or three layers. exist Figure 2 ~ Figure 4 In , the easily tearable laminated film 100, 200, 300 of this embodiment is shown. Here, for example, as figure 2 As shown, the first layer is a 2-layer structure of easy-tearable stretch film 18, and the second layer is various sealing layer films 19; figure 2 As shown, the first layer is a 3-layer structure of various substrate films 20, the second layer is an easily tearable stretch film 18, and the third layer is various sealing layer films 19; image 3 Shown; The first layer is a 3-layer structure of easy-tearable stretch film 18, the second layer is various substrate films 20, and the third layer is various sealing layer films 19.

[0071] As the material of the base film 20, for example, PET (polyethylene terephthalate), EVOH (ethylene-vinyl...

Embodiment 1

[0081] (Manufacture of tearable stretch film)

[0082] With respect to the mixture obtained by mixing Ny6 pellets and MXD6 pellets at a ratio of 70 parts by mass and 30 parts by mass, respectively, 15% by mass of a thermal history material (the melting point of MXD6) that has been melt-mixed once and pelletized according to the compounding ratio is blended. is 236°C). The dry blend was melted and kneaded in an extruder at 270° C., and the melt was extruded from a die into a cylindrical film, which was then quenched with water to produce a base film.

[0083] In addition, the melting point of MXD6 was measured by using a differential scanning calorimeter (DSC) manufactured by Perkin Elmer Co., Ltd., from 50°C to 280°C at a heating rate of 10°C / min. In all cases, the initial value was taken as the melting point.

[0084] As Ny6, nylon 6 [UBE Nylon 1023FD (trade name), relative viscosity ηr=3.6] manufactured by Ube Industries, Ltd. was used, and as MXD6, m-xylylene adipamide ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com