Low-temperature-level mixed refrigerant suitable for two-stage multiplex refrigerating system

A technology of mixed refrigerant and cascade refrigeration, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of low temperature refrigeration performance of refrigerants, reduced lubricating characteristics of compressors, poor mutual solubility of lubricating oils, etc. The effect of increasing the amount, increasing the evaporation pressure, and increasing the mutual solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

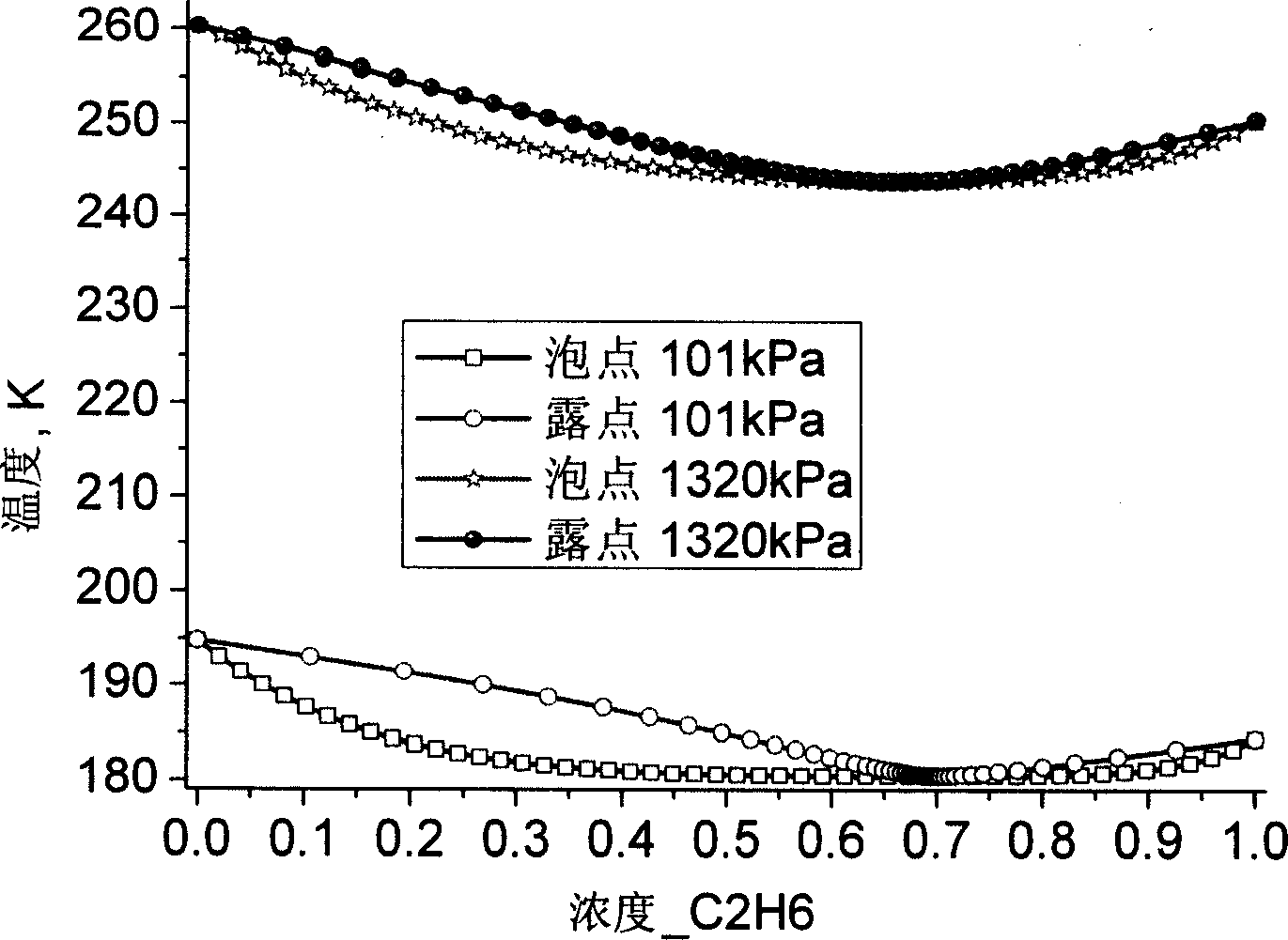

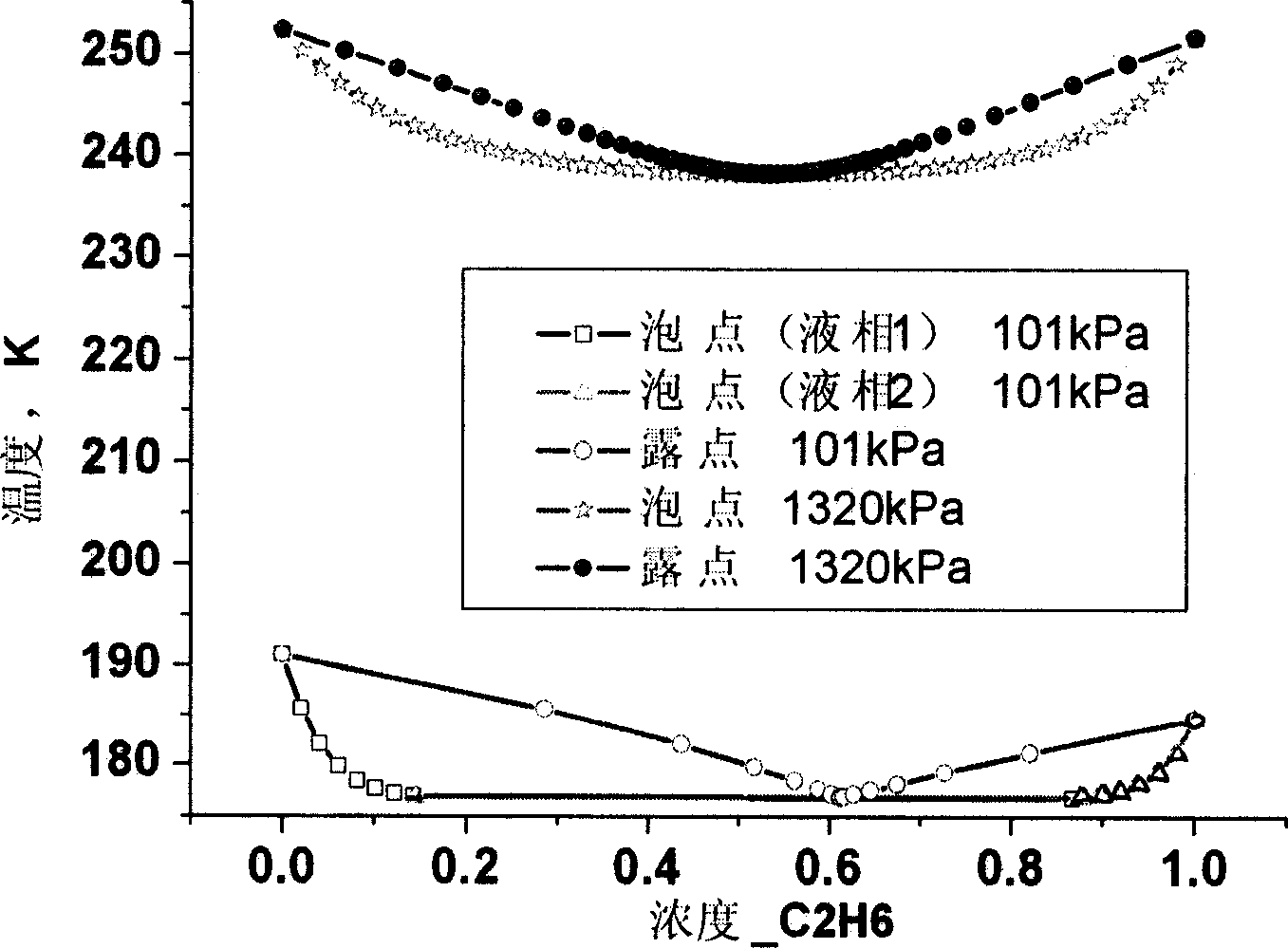

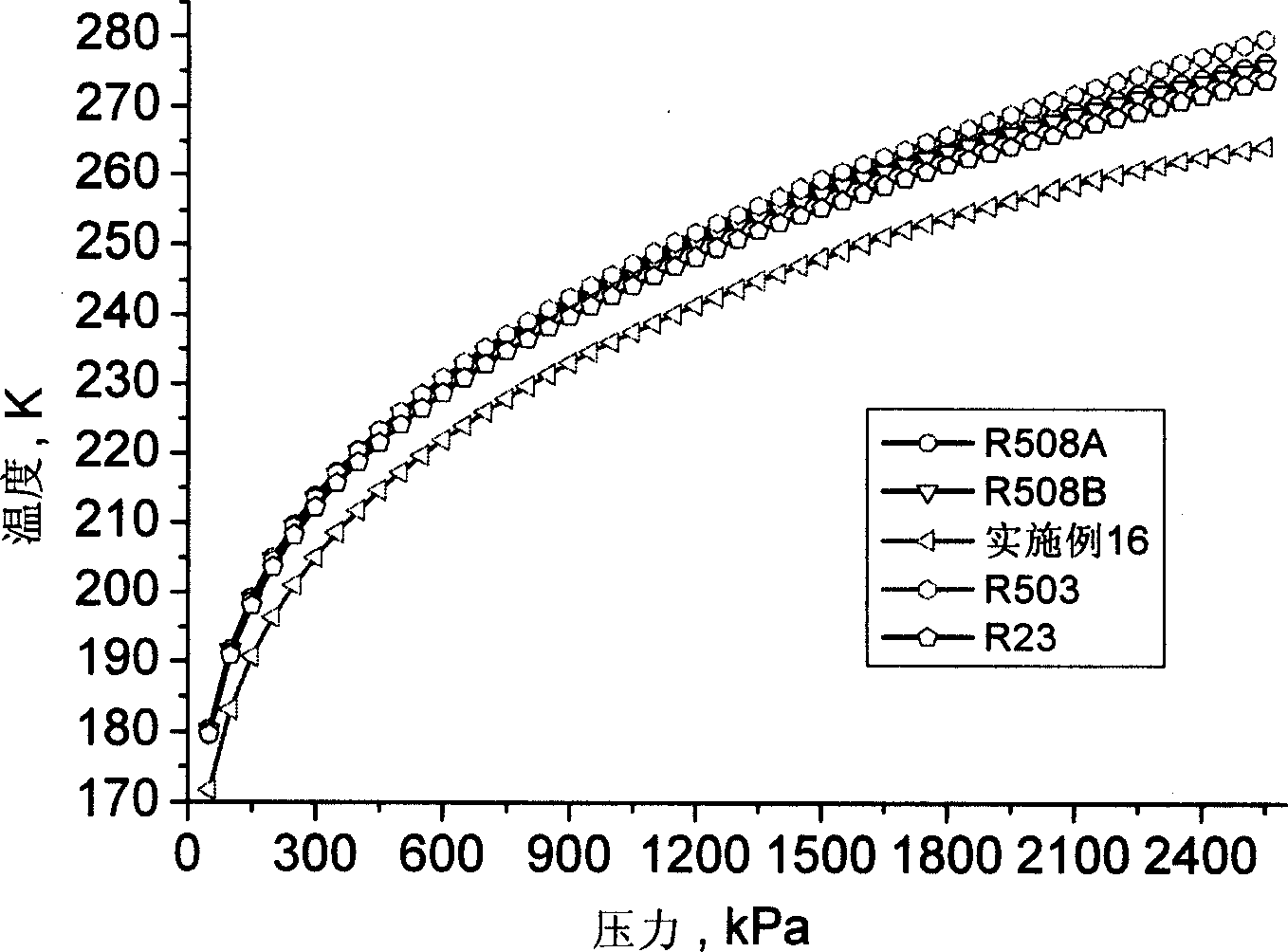

[0026] Example 1: ethane with a molar concentration of 25% and perfluoroethane with a molar concentration of 75% are physically mixed at room temperature to obtain a low-temperature-grade mixed refrigerant that can be applied to a two-stage cascade refrigeration system.

Embodiment 2

[0027] Example 2: ethane with a molar concentration of 30% and perfluoroethane with a molar concentration of 70% are physically mixed at room temperature to obtain a low-temperature-grade mixed refrigerant applicable to a two-stage cascade refrigeration system.

Embodiment 3

[0028] Example 3: ethane with a molar concentration of 55% and perfluoroethane with a molar concentration of 45% were physically mixed at room temperature to obtain a low-temperature-grade mixed refrigerant applicable to a two-stage cascade refrigeration system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com