Heat-pipe measuring device

A heating device and heat pipe technology, applied in the field of heat conduction, can solve the problems of large interface thermal resistance, low heat transfer efficiency, affecting the accuracy and reliability of a plate heat pipe measuring device, etc., and achieve a high degree of measurement accuracy and reliability. The effect of reducing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution will be described in further detail below in conjunction with the accompanying drawings.

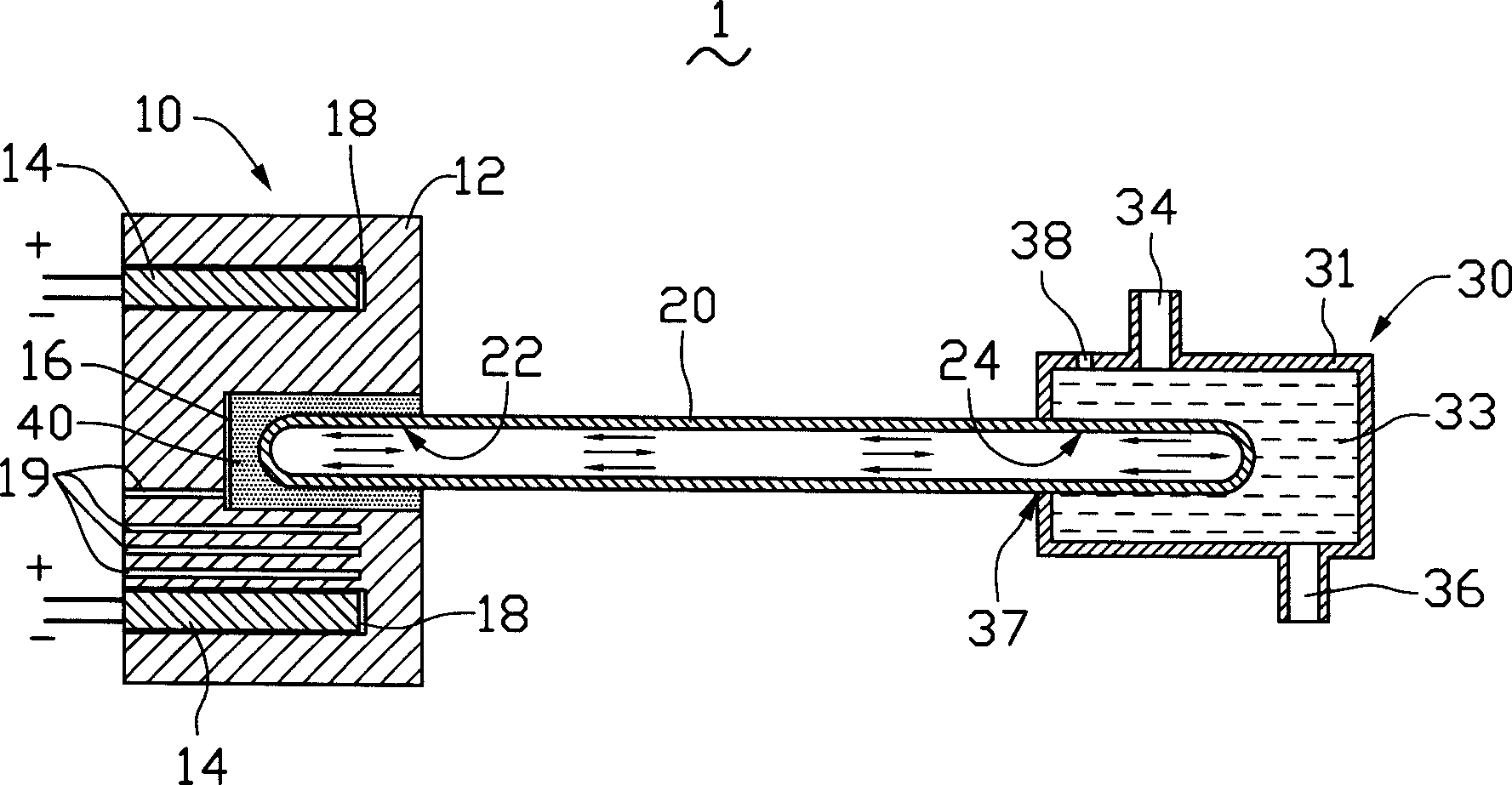

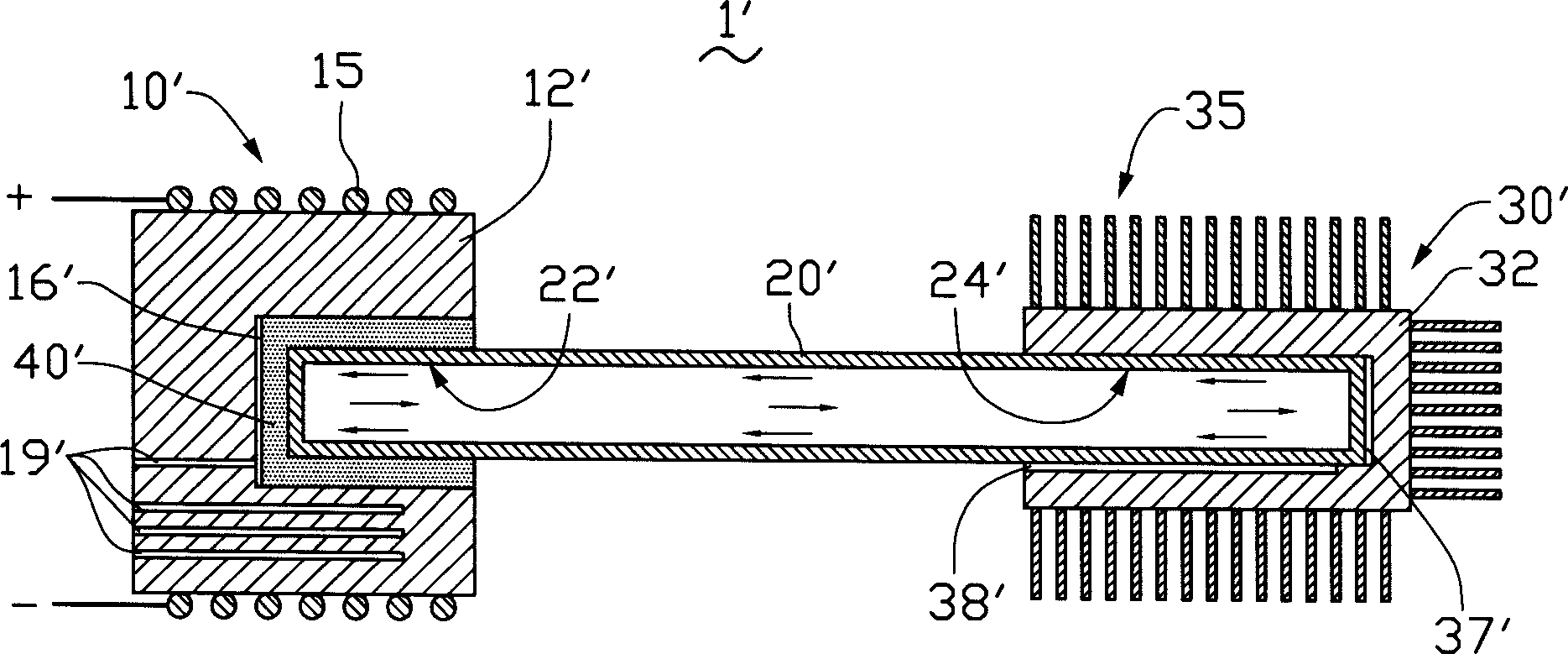

[0024] see figure 1 , is a schematic diagram of the heat pipe measurement device in the first embodiment of the present technical solution, the heat pipe measurement device 1 includes: a heating device 10, a cooling device 30, and the heating device 10 and the heat pipe 20 to be measured A thermal interface material 40 between the thermal contact interfaces. The heat pipe 20 to be tested can be a flat heat pipe, a single pipe heat pipe or a separate (loop type) heat pipe, and the heat pipe 20 to be tested in this embodiment is a single pipe heat pipe.

[0025] The heating device 10 of the present embodiment includes a metal heating block 12 and a plurality of heating rods 14. The heating block 12 can be in the shape of a cube or a cylinder. There are 18 multiple slots. The groove 16 and one end of the heat pipe 20 are basically closely matched with each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com