Semiconductor light-emitting device and method for manufacturing same

A technology for a light-emitting element and a manufacturing method, which can be applied to semiconductor devices, semiconductor lasers, electrical components, etc., can solve problems such as peeling and poor adhesion, and achieve the effects of suppressing invalid light emission and improving external quantum efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

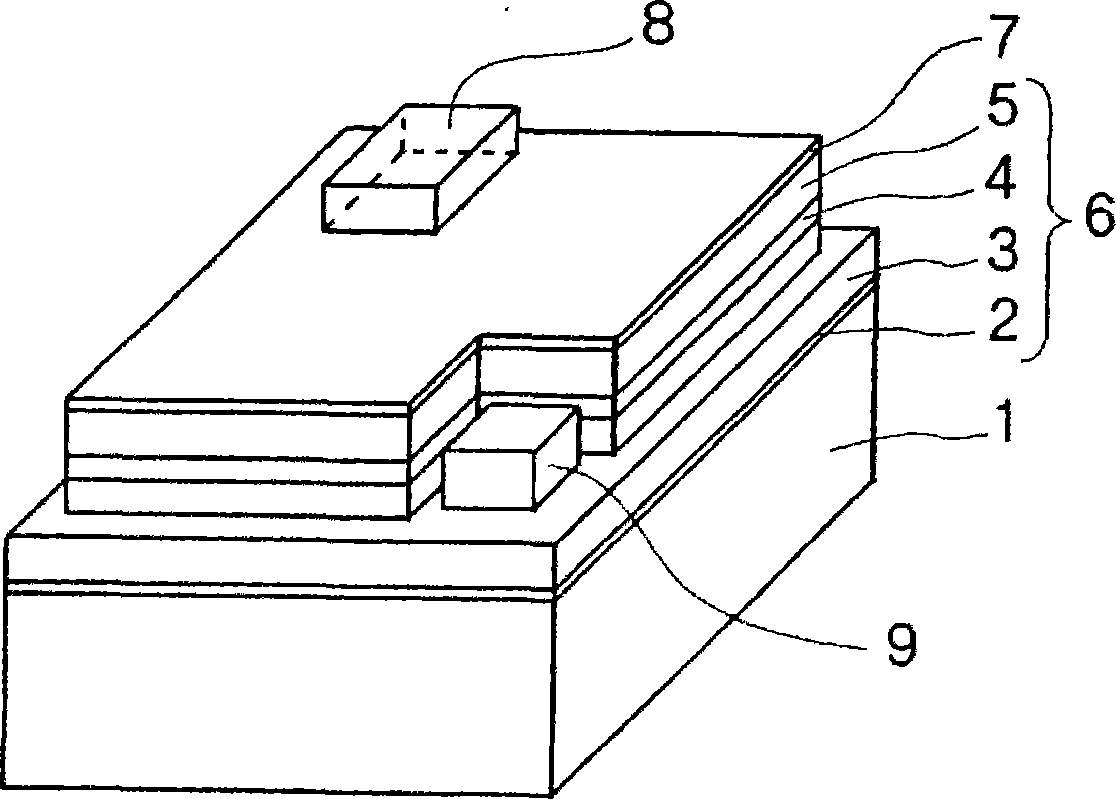

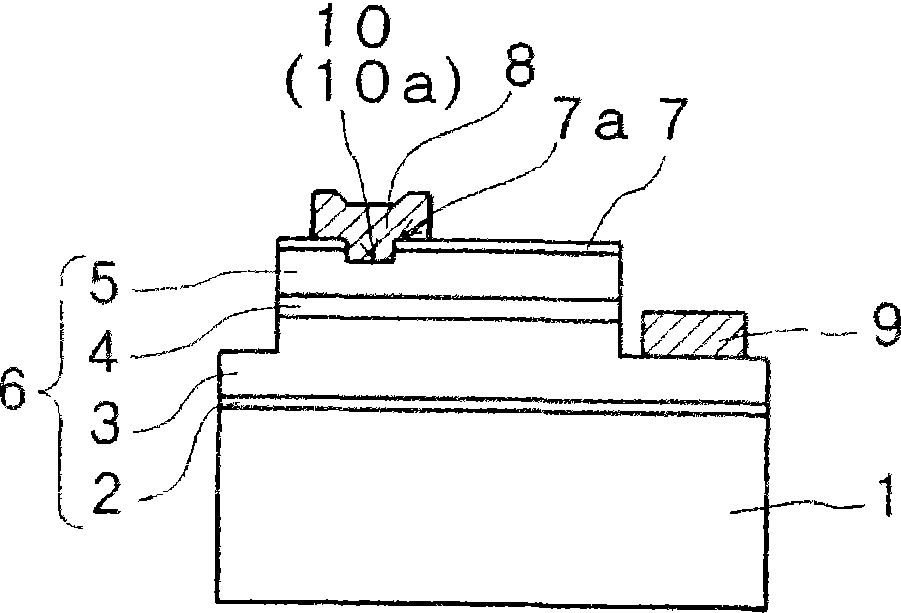

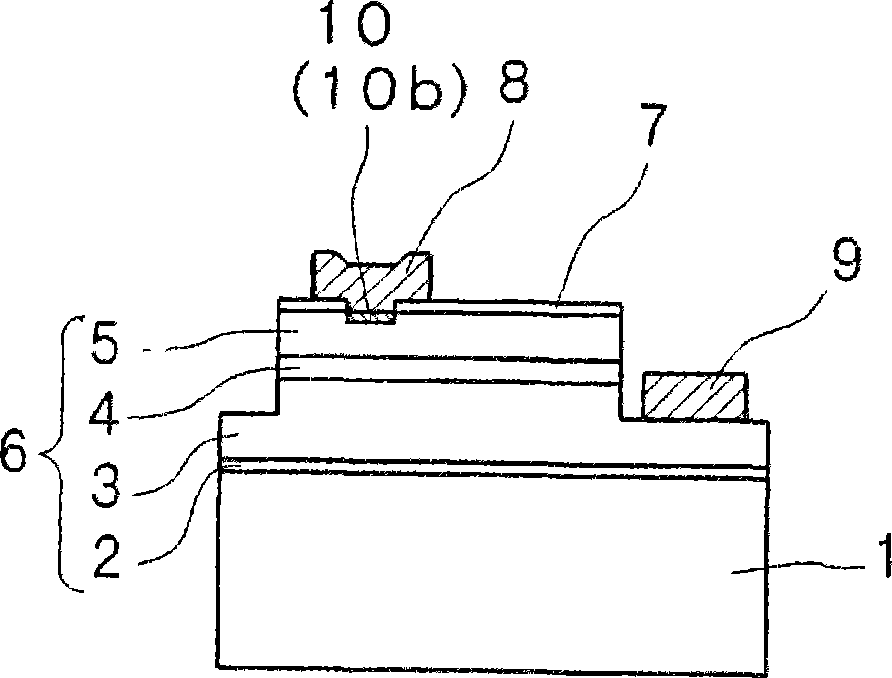

[0034] Next, the semiconductor light-emitting element of the present invention and its manufacturing method will be described with reference to the drawings. The semiconductor light-emitting device of the present invention, an explanatory diagram of a perspective view and a cross-sectional view of an embodiment thereof, is shown in FIG. In the laminated portion 6 , a light-transmitting conductive layer 7 is provided on the surface of the semiconductor laminated portion 6 . A part of the translucent conductive layer 7 is removed, and an upper electrode (electrode pad) 8 is provided in contact with the exposed surface of the semiconductor laminate 6 and the translucent conductive layer 7 . In the present invention, a structure is formed in which a portion of the translucent conductive layer 7 is removed, and a current suppressing mechanism 10 (10a) is provided on the surface of the semiconductor lamination layer 6 exposed from the opening 7a, thereby forming a secure upper elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com