Low temperature saccharification process for corn powder

A low-temperature saccharification and corn flour technology, applied in fermentation and other directions, can solve the problems of low starch conversion rate, complex process, high production cost, etc., achieve low liquefaction temperature, simple process, and energy saving effects

Inactive Publication Date: 2010-11-24

NANJING TECH UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The technical problem to be solved by the present invention is to propose a low-temperature saccharification process of corn flour in order to overcome the shortcomings of the above-mentioned technical starch conversion rate reduction, high production cost due to high liquefaction temperature, high energy consumption, and complicated process.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

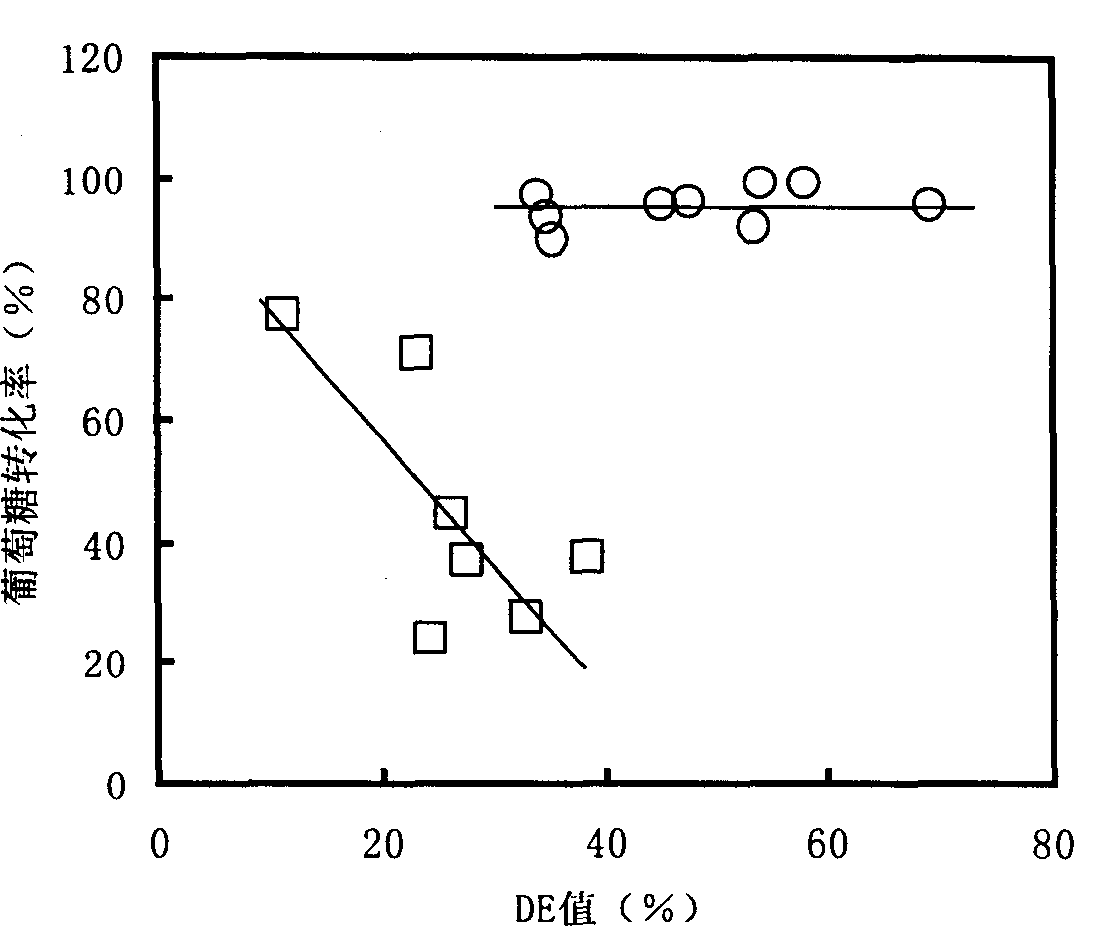

Login to View More Abstract

The present invention relates to saccharification process, and is especially low temperature double enzyme corn powder saccharifying process. The technological scheme of the present invention includes dry or wet crushing corn in a planetary ball mill, and saccharifying corn powder or corn starch in a double enzyme process. The present invention describes the effects of material granularity, material liquid concentration, liquefying temperature, enzyme amount and other factors on the liquefying speed and glucose conversion rate, and develops low temperature corn powder saccharifying process. The present invention has lower liquefying temperature, low power consumption, high glucose conversion rate, well preservation of protein, fat, inorganic elements, vitamins and components in corn material, and simple technological process.

Description

Low temperature saccharification process of corn flour Technical field: The invention relates to a double-enzyme saccharification process, in particular to a low-temperature double-enzyme saccharification process for corn flour. Background technique: Starch sugar can be made from any kind of starchy crops such as: rice, wheat, cassava, oats, sweet potatoes, potatoes, etc. Among them, corn is better for sugar production. This is because the cost of making sugar from cornstarch is relatively low, but the sugar yield is high, and the by-products produced by corn in the sugar making process are relatively concentrated, and its sugar making benefits are also high. Therefore, cornstarch sugar is widely used. As the main industrial raw material, it can be used in food sugar industry, fermentation industry, medicine, chemical industry and other industries. Specifically, corn starch sugar can be used in the food sugar industry to produce various starch sugars such as: maltose, de...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C12P19/14

Inventor 缪冶炼吴琴燕夏发俊

Owner NANJING TECH UNIV

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com