Low temperature saccharification process for corn powder

A low-temperature saccharification and corn flour technology, which is applied in fermentation and other directions, can solve the problems of high production cost, high liquefaction temperature, and low starch conversion rate, and achieve the effects of improving the quality of saccharification products, reducing the liquefaction reaction temperature, and increasing the liquefaction reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

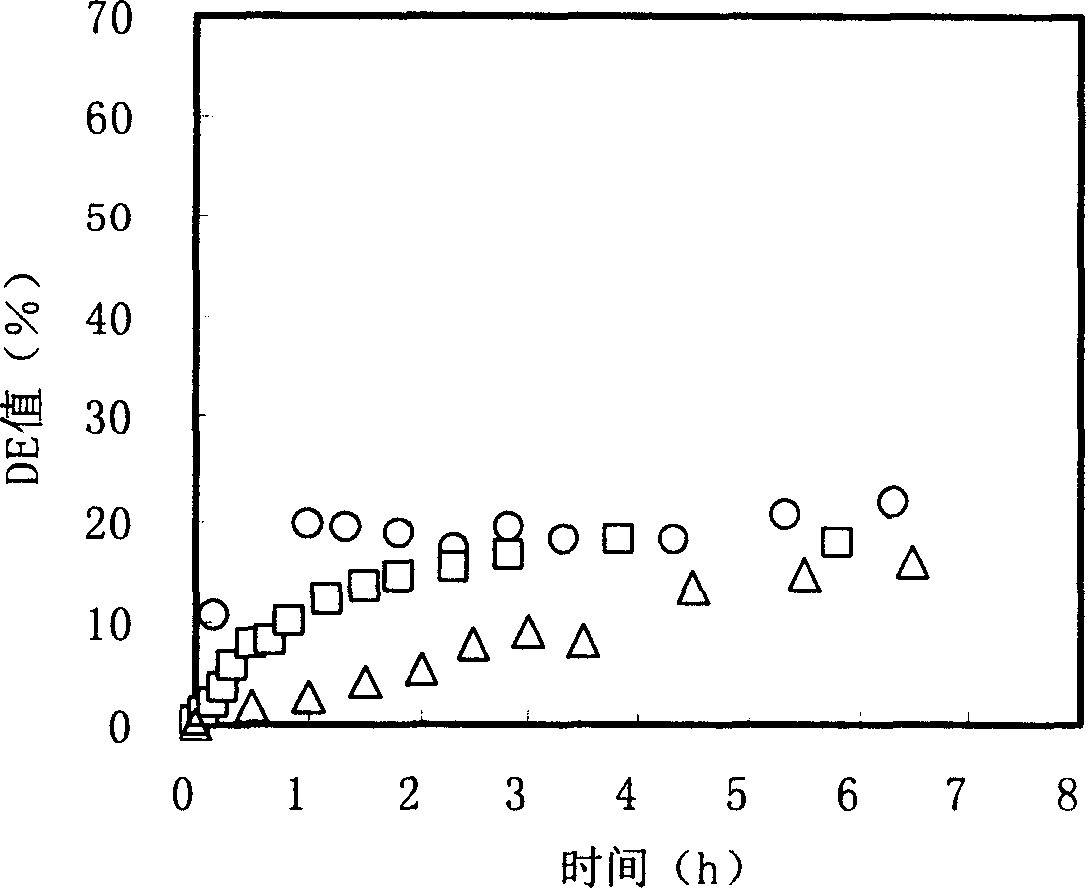

[0060] Example 1: Under the conditions of feed liquid pH 6.0-6.5, feed liquid concentration 10%, enzyme dosage 10U / g-corn flour raw material, and liquefaction temperature of 50°C, 60°C, and 70°C, medium-temperature α-starch was used Enzymes on commercially available corn flour (D 50 =273.6 μm) was liquefied, and changes in the DE value were investigated. The result is as figure 1 shown.

Embodiment 2

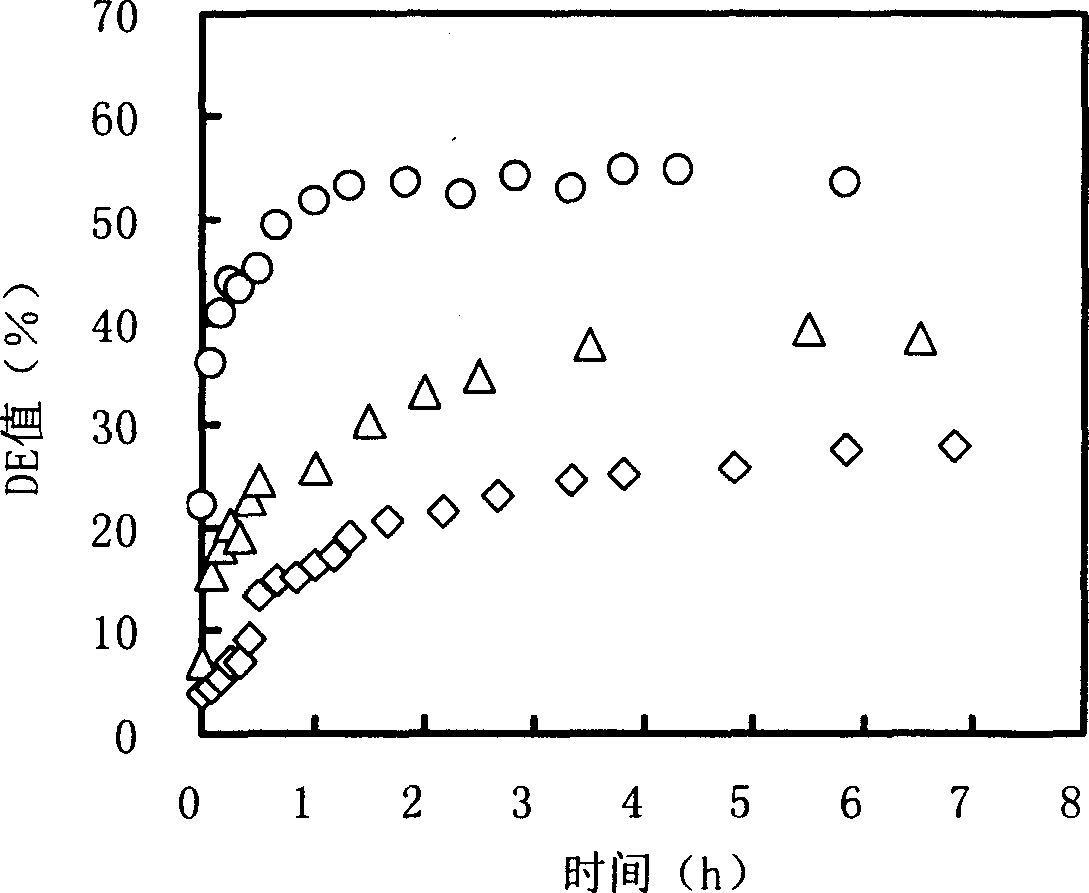

[0061] Example 2: Under the conditions of feed liquid pH6.0-6.5, feed liquid concentration 10%, enzyme dosage 10U / g-corn flour raw material, and liquefaction temperature of 30°C, 50°C, and 70°C, medium-temperature α-starch was used Enzyme on fine corn flour (D 50 =17.1 μm) was liquefied, and changes in the DE value were investigated. The result is as figure 2 shown.

Embodiment 3

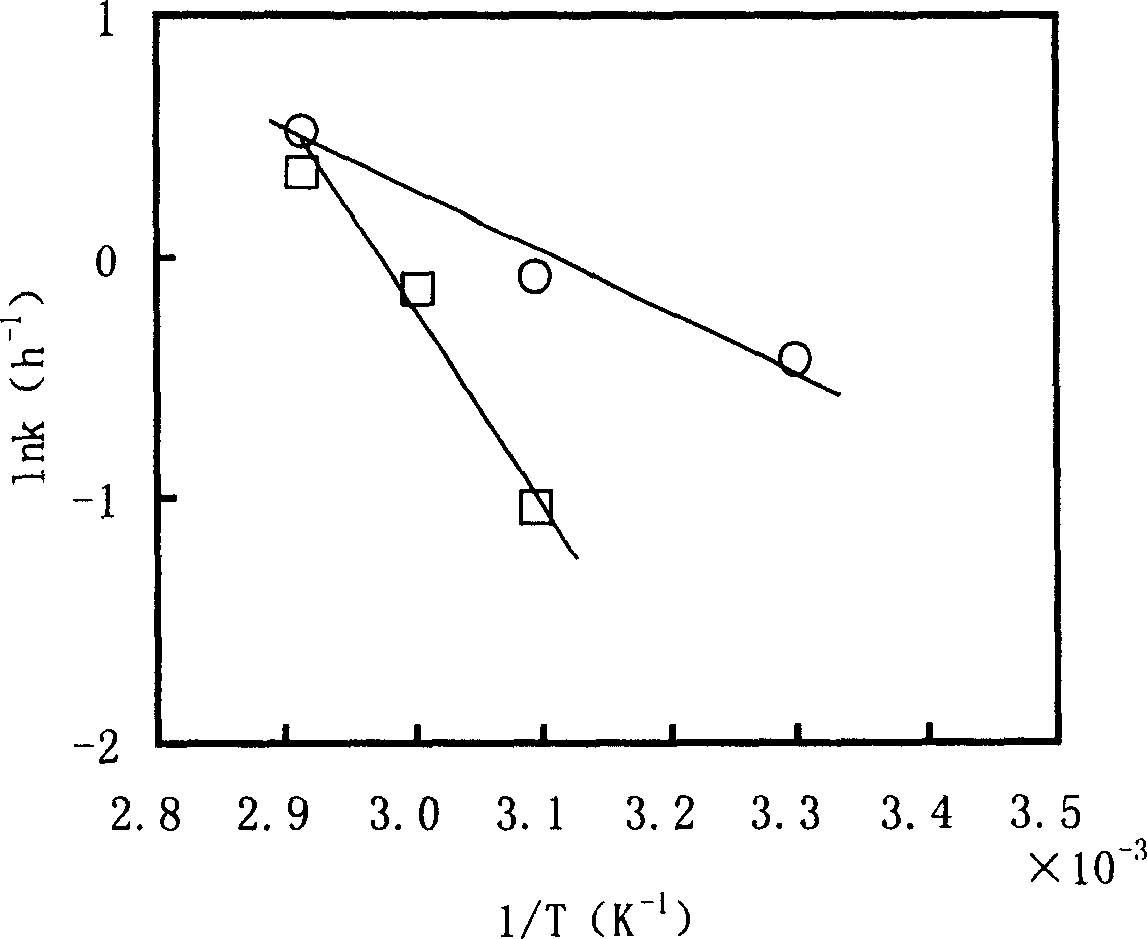

[0062] Embodiment 3: Carry out reaction kinetics analysis to the change of DE value in embodiment 1 and embodiment 2. The result is as image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com