Liquid slag wind chilling treating method for improving high titanium type blast furnace slag particle property

A treatment method, a high-titanium type technology, applied in the field of improving the performance of high-titanium type blast furnace slag, can solve the problems of large-scale use of granulated high-titanium type blast furnace slag, and can not be used on a large scale, and achieve important environmental Ecological benefits, savings in construction and use costs, and the effects of eliminating environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

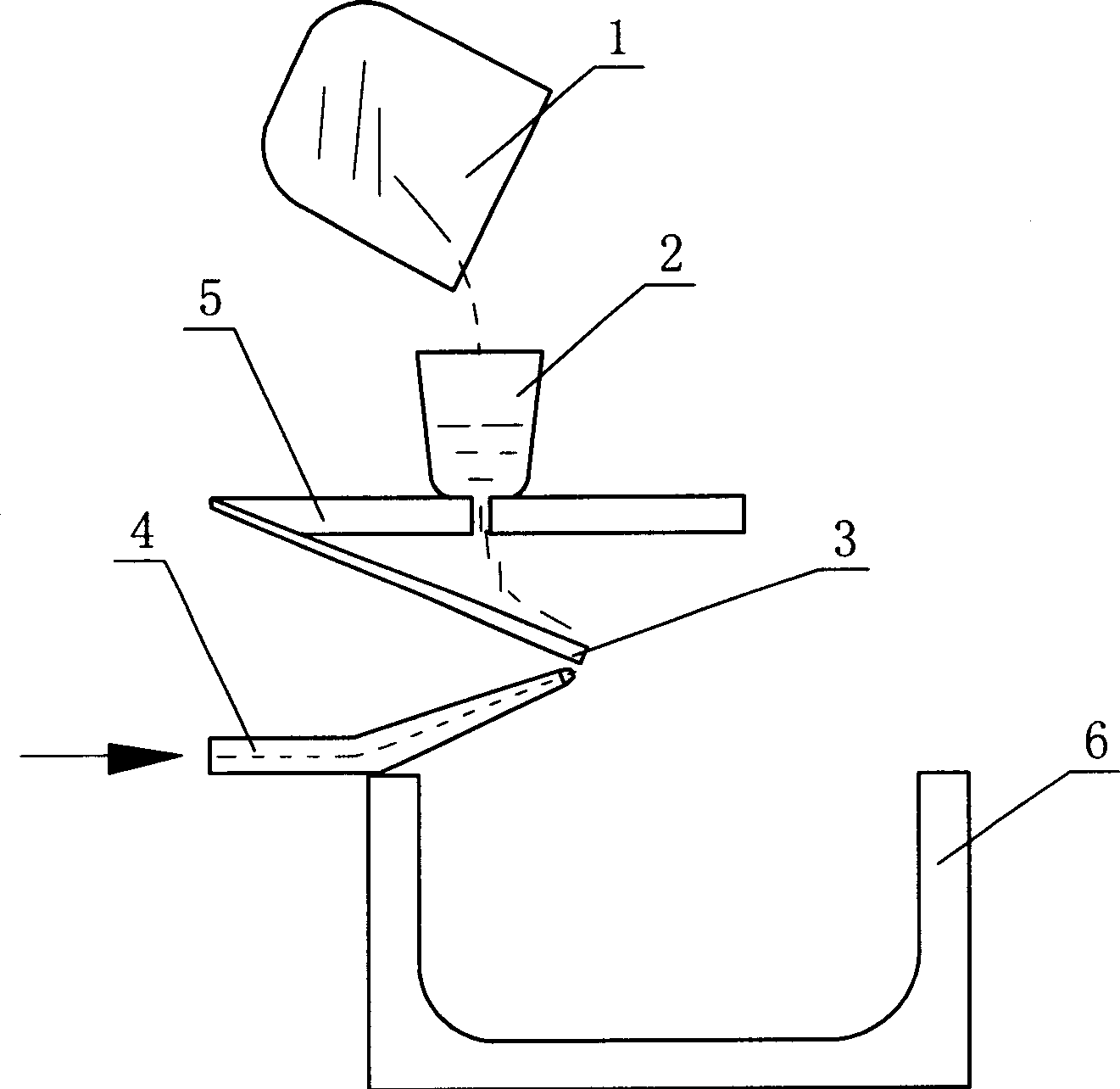

Method used

Image

Examples

specific Embodiment

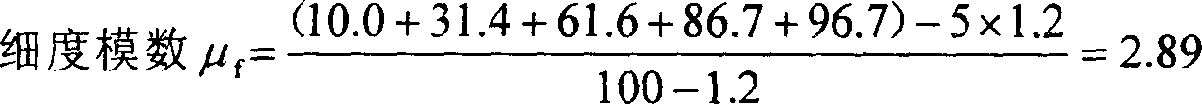

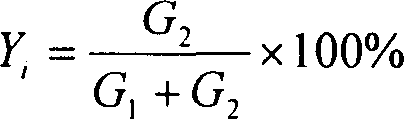

[0038] Specific embodiment: The technological parameters of partial air quenching experiment of high titanium type blast furnace slag are shown in Table 1.

[0039] Stoves

serial number

before the nozzle

pressure

(MPa)

Density

(kg / m3)

average flow

speed(m / s)

average motion

Energy (MPa)

wind nibs

Slag amount

(kg)

When the wind breaks

room(s)

Air-to-slag ratio

(m3 / kg

)

1

0.2

311.23

0.063

4

25

0.0457

2

0.2

311.23

0.063

4

26

0.0475

3

0.2

311.23

0.063

4

24

0.0439

4

0.2

311.23

0.063

4

23

0.0421

5

0.14

2.80

295.5

0.122

3.2

17

0.0369

6

0.12

2.57

281.3

0.102

2.0

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com