Mild hot formation method for making magnesium alloy shell of cell phone and mould specially for the same

A technology of warm forming and mobile phone casing, which is applied in the field of alloy plate stamping and forming, which can solve the problems of reducing the plastic deformation ability of the plate, poor plastic formability, and expensive product cost, and achieves uneven non-lubricating layer, strong rigidity, and low production cost. Effect

Inactive Publication Date: 2007-01-31

INST OF METAL RESEARCH - CHINESE ACAD OF SCI

View PDF0 Cites 44 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Mainly due to the close-packed hexagonal crystal structure of metal magnesium, the plastic formability of most magnesium alloys at room temperature is very poor. Raising the forming temperature will effectively improve its formability, usually in the temperature range of 250-400°C Processing and forming will bring the disadvantages of relatively complex mold system, and the cost of the product is also relatively expensive, and when the heating time is too long, it is easy to cause coarse grains inside the plate, which will seriously reduce the plastic deformation ability of the plate. At this time, the blank is very brittle, and it is very easy to crack at the rounded corner of the punch during deep drawing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0042]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

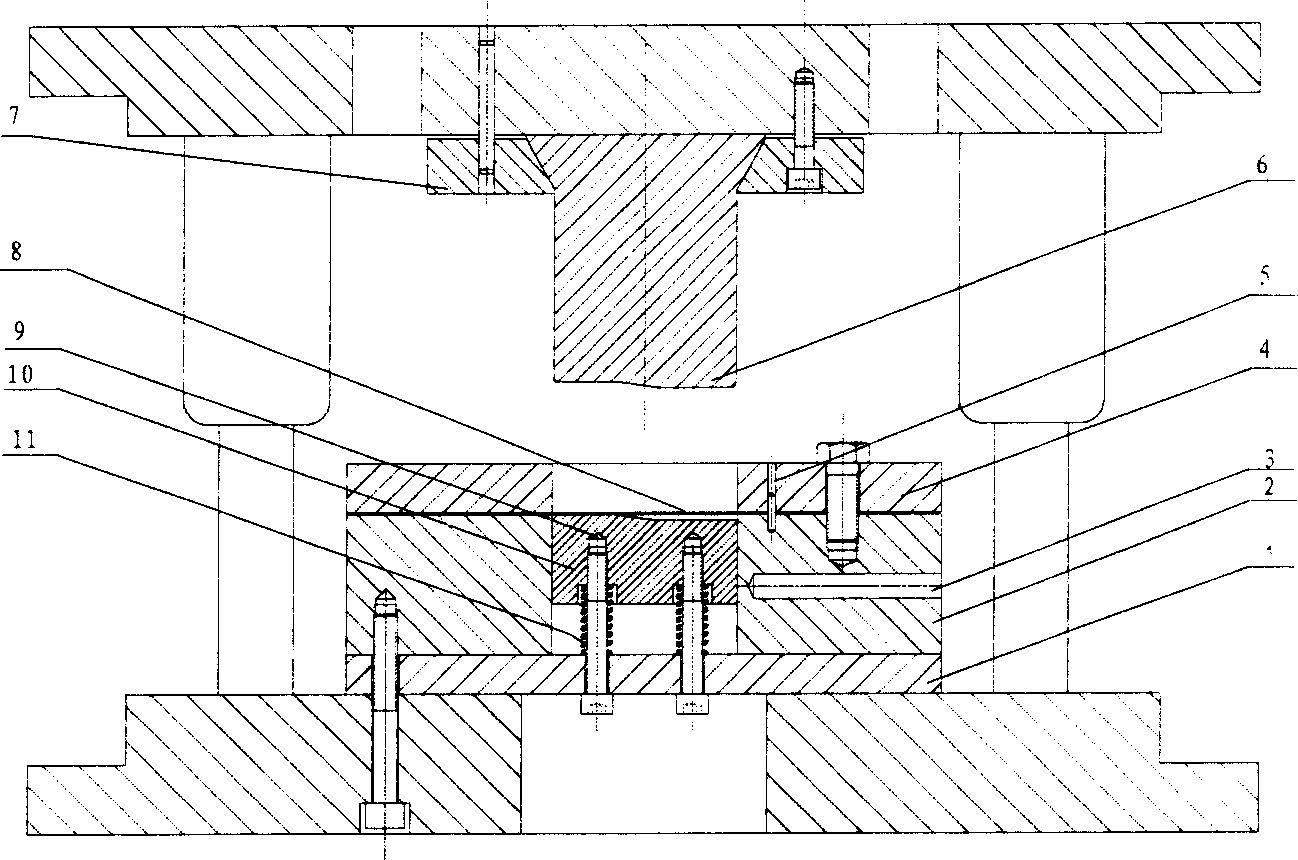

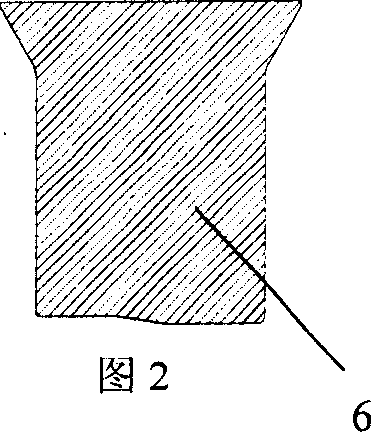

A thermal shaping method for the Mg-alloy shell of mobile telephone features use of draw technology with a dedicated die set, which includes such steps as heating edge pressing ring and female die to 170-180 deg.C, coating lubricant onto die set and raw black of said Mg-alloy shell, heating the raw black, pre-heating the male die to 70-100 deg.C, and die pressing at 170-180 deg.C for drawing.

Description

technical field [0001] The invention relates to an alloy plate stamping forming technology, in particular to a warm forming method for a magnesium alloy mobile phone casing and a special mold thereof, which are mainly used in the forming of a magnesium alloy plate through a warm drawing process. Background technique [0002] Metal magnesium and its alloys are the lightest structural metal materials used in engineering so far. Magnesium alloys characterized by light weight, good rigidity, good metallic luster, good electromagnetic shielding and easy recycling have become modern automobiles, electronics, The preferred material for communication and other industries. At present, magnesium alloy products are obtained by casting methods. The disadvantages are low yield, more holes and looseness, low strength, and poor ductility, which cannot meet the higher requirements of the product. Due to the process requirements, the wall thickness of the casting itself cannot be too thin, w...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21D22/20B21D37/10

Inventor 任丽梅张士宏徐永超王忠堂李章刚郑文涛

Owner INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com