Impeller cylinder combination of impeller motor

An engine and impeller technology, applied in the field of impeller-cylinder combination structure, can solve the problems of no heat recovery and reuse facilities, short stroke of the piston in the cylinder, large gap between the blade and the cylinder, etc., to improve work efficiency, prevent air leakage, good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

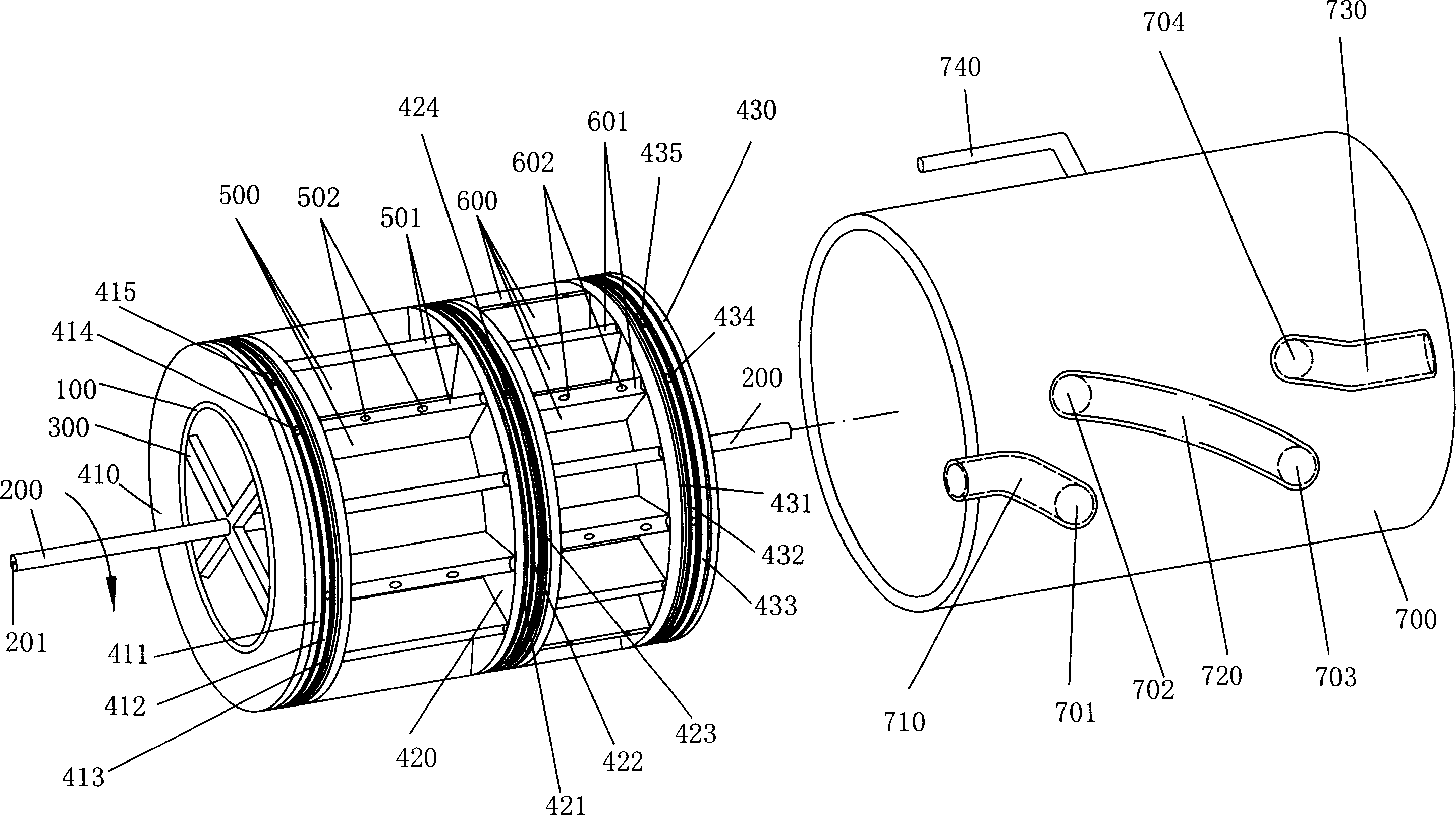

[0018] The deployment structure of an embodiment of the impeller cylinder combination of the impeller engine of the present invention, such as figure 1 shown. It consists of a cylindrical cylinder and an impeller installed in the cylinder and connected to the main shaft.

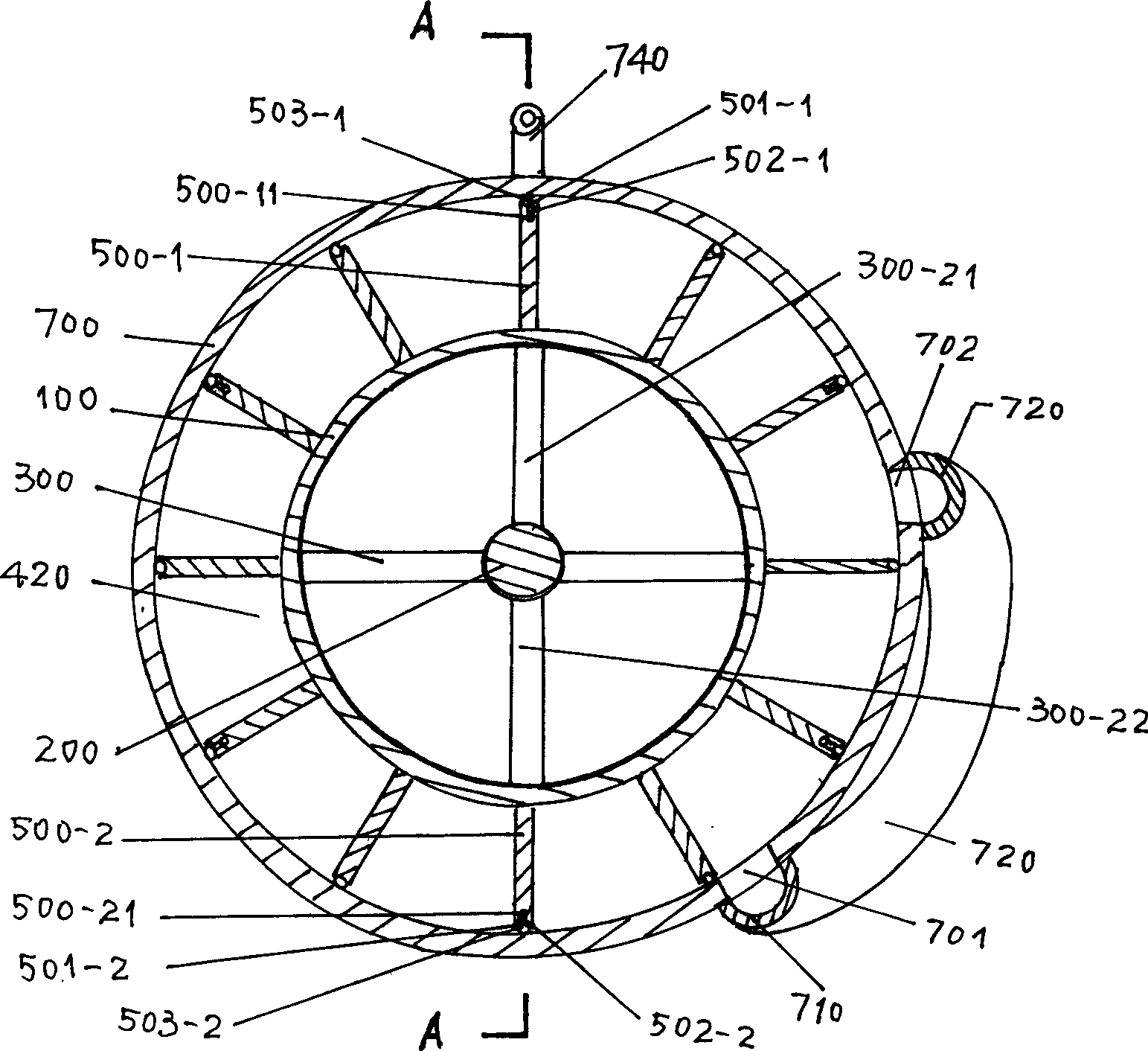

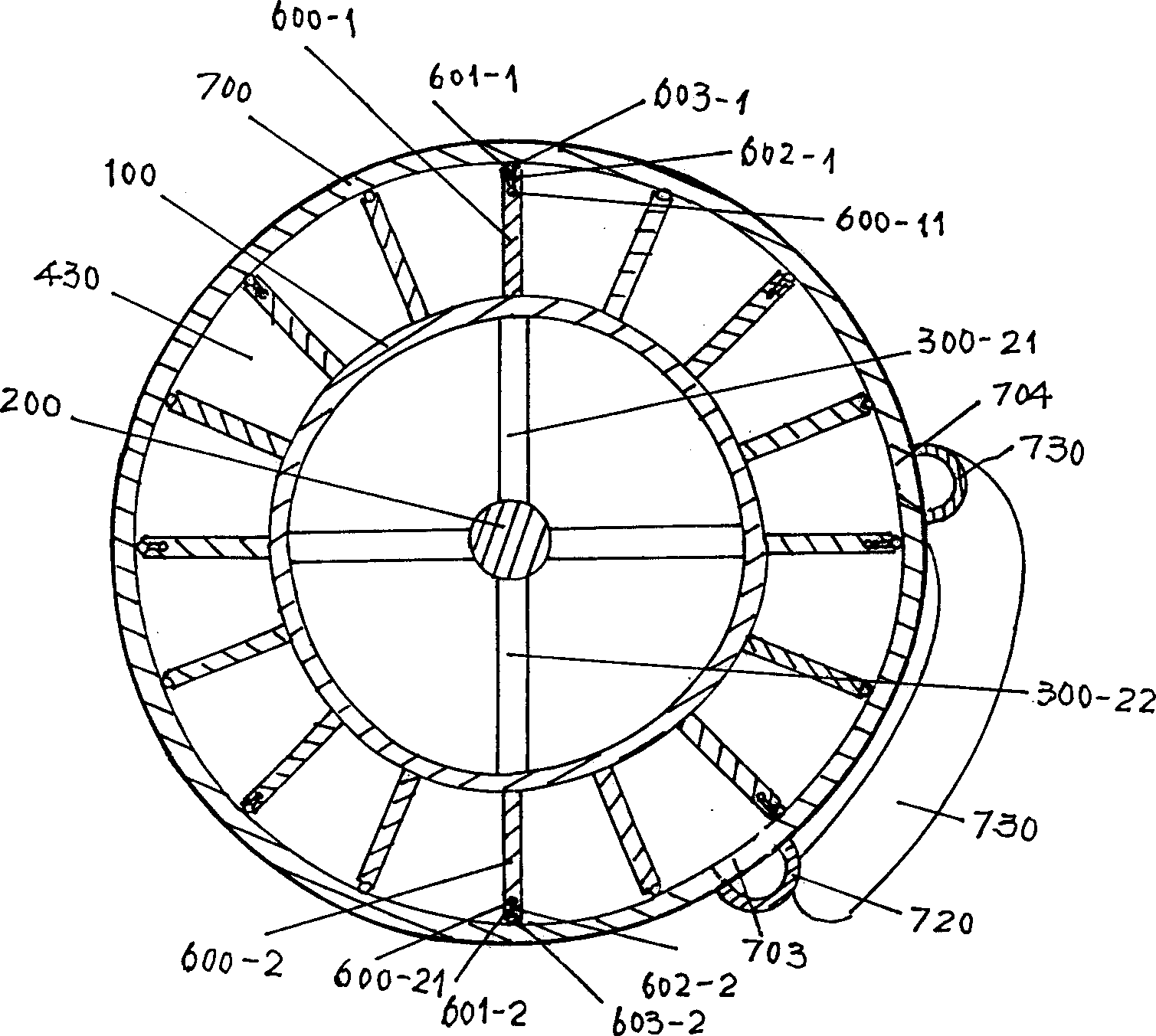

[0019] Its impeller has a cylindrical rotor 100, and four radial connecting rods 300 are evenly arranged on the inner circumference of both ends of the rotor 100 to connect the main shaft 200; The annular partitions 410, 420, 430 of the same size form two ring grooves, one wide and one narrow. Please see figure 2 , 12 radially wide vanes 500 perpendicular to the separators 410 and 420 are evenly arranged in the wider ring groove on the left; please refer to image 3 16 radially narrow blades 600 perpendicular to the separators 420 and 430 are evenly arranged in the narrower ring groove on the right side.

[0020] Please see Figure 4 The partition plate 410 at the left end of the rotor 100 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com