Method and system for designing optical shield layout and producing optical shield pattern

A mask and pattern technology, applied in the field of lithography process, to achieve the effect of wide utilization value, product structure improvement, and improvement of image distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the method and system for designing the layout of the mask and generating the pattern of the mask according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Embodiments, methods, steps, structures, features and effects thereof are described in detail below.

[0073] This disclosure is related to the field of optics or lithography. To illustrate the present disclosure, several specific examples and types of systems, formulations, patterns, and substrates are described and discussed below. It should be appreciated, however, that these specific examples are intended to teach broader inventive concepts, and those skilled in the art can readily apply the teachings of this disclosure to other related fields.

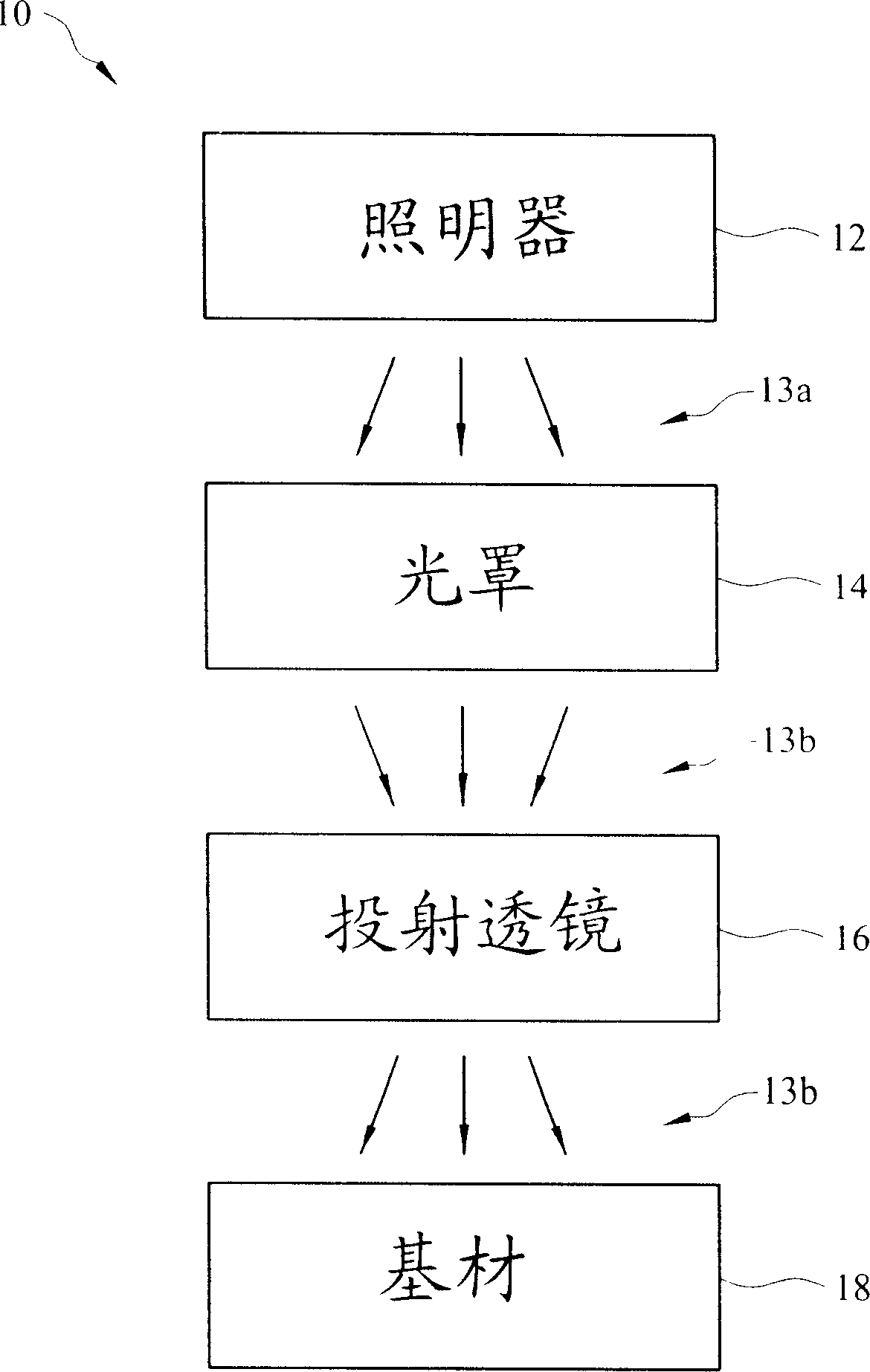

[0074] see figure 1 As shown, semiconductor lithog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com