Memory array module

A memory array and memory chip technology, which is applied in the direction of instruments, electrical digital data processing, digital data processing parts, etc., can solve the problems of high personnel costs, empty welding, and inability to meet the processing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

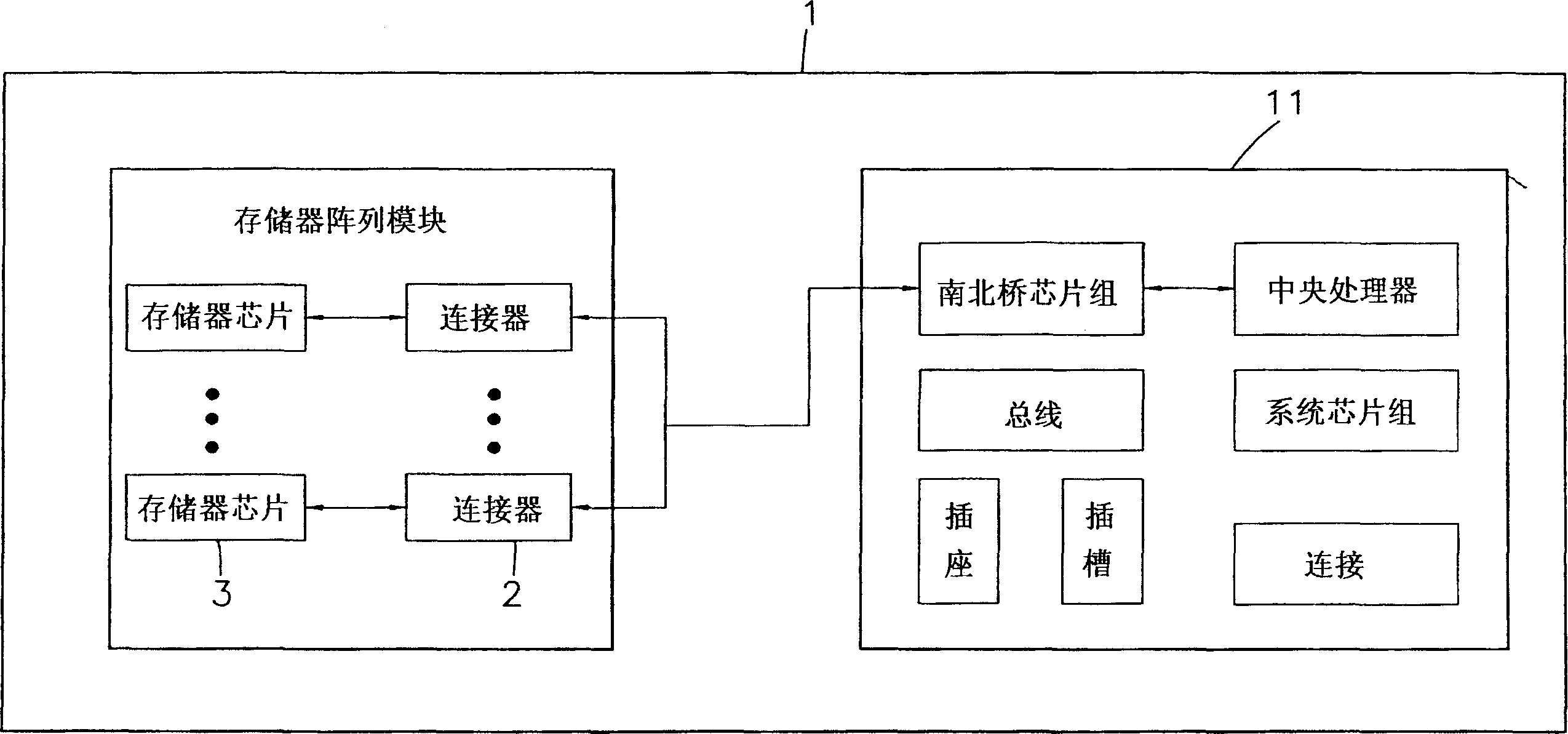

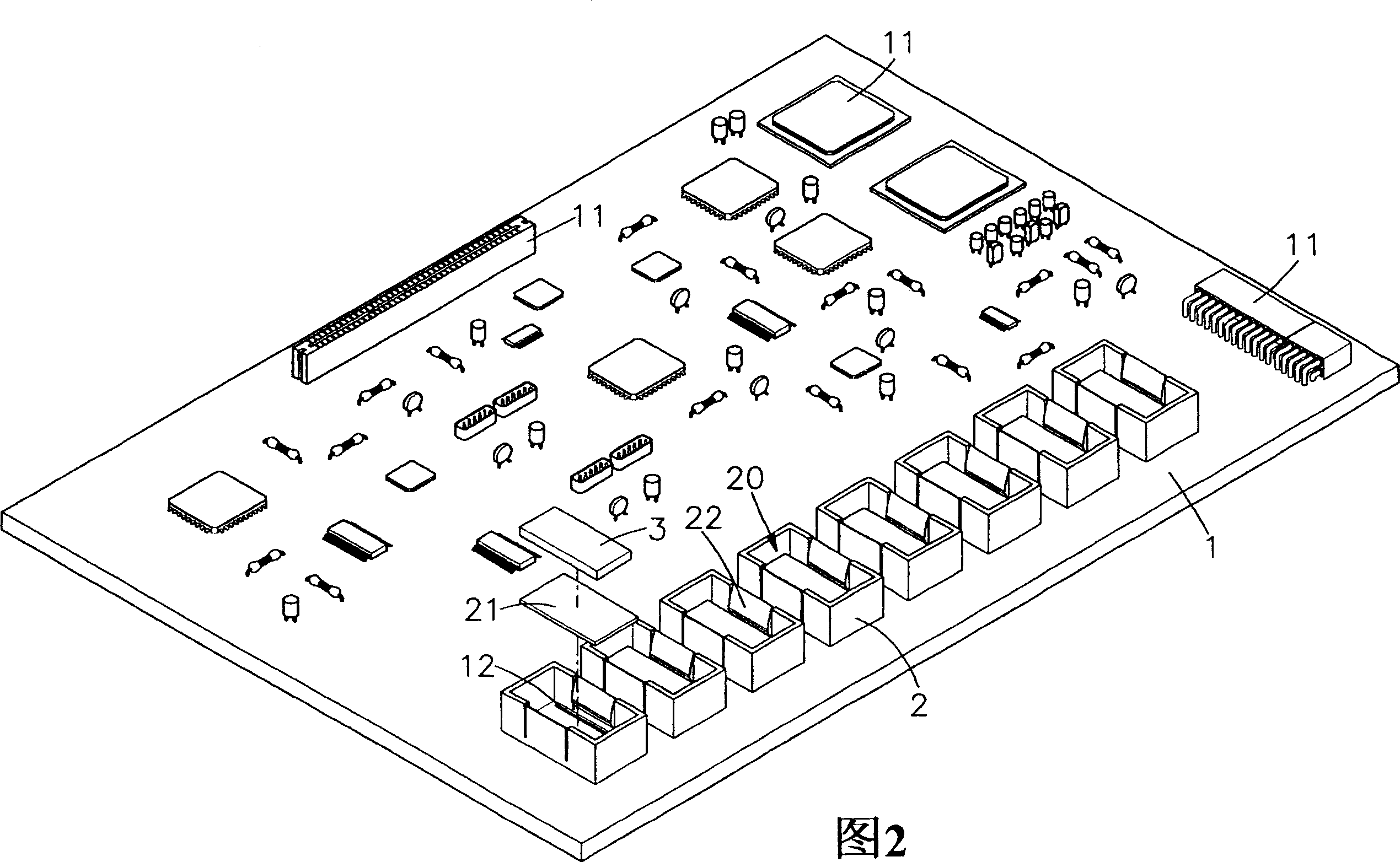

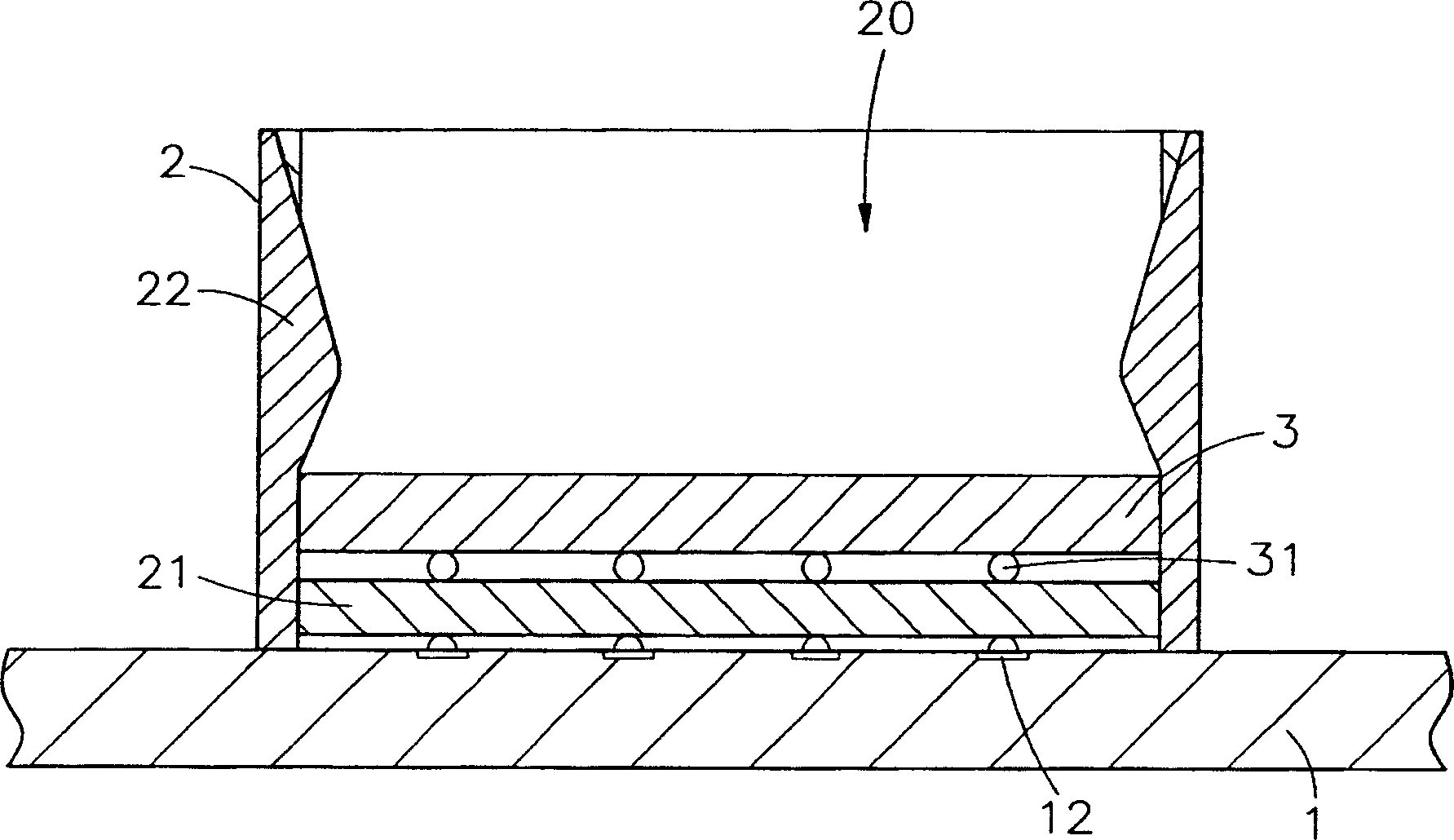

[0045] see figure 1 As shown, it is a schematic block diagram of the present invention. It can be clearly seen from the figure that the memory array module of the present invention is mainly provided with circuit contacts 12 and related electronic parts 11 on the motherboard 1, and its electronic parts 11 can be system Chipset, central processing unit, bus, slot, socket or connection port, etc., and two or more connectors 2 are additionally arranged on the motherboard 1, wherein each connector 2 provides a memory chip 3 on the In the welding state, it is combined and positioned, and the memory chip 3 can be electrically connected to the preset circuit contact 12 on the main board 1. Therefore, when the main board 1 is processed and etched with the circuit contact 12 in the present invention, the connector 2 can be connected simultaneously. The required circuit contacts are arranged on the main board 1 to simplify the overall processing flow of the main board 1 and effectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com