Air gap eccentric checking device and method for single-phase inductor

A technology of air gap eccentricity and detection devices, which is applied in the direction of measuring devices, electromechanical devices, asynchronous induction motors, etc., can solve the problems of large and different eccentricity, and cannot judge qualified products, etc., and achieve the effect of reliable judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Implementation form 1.

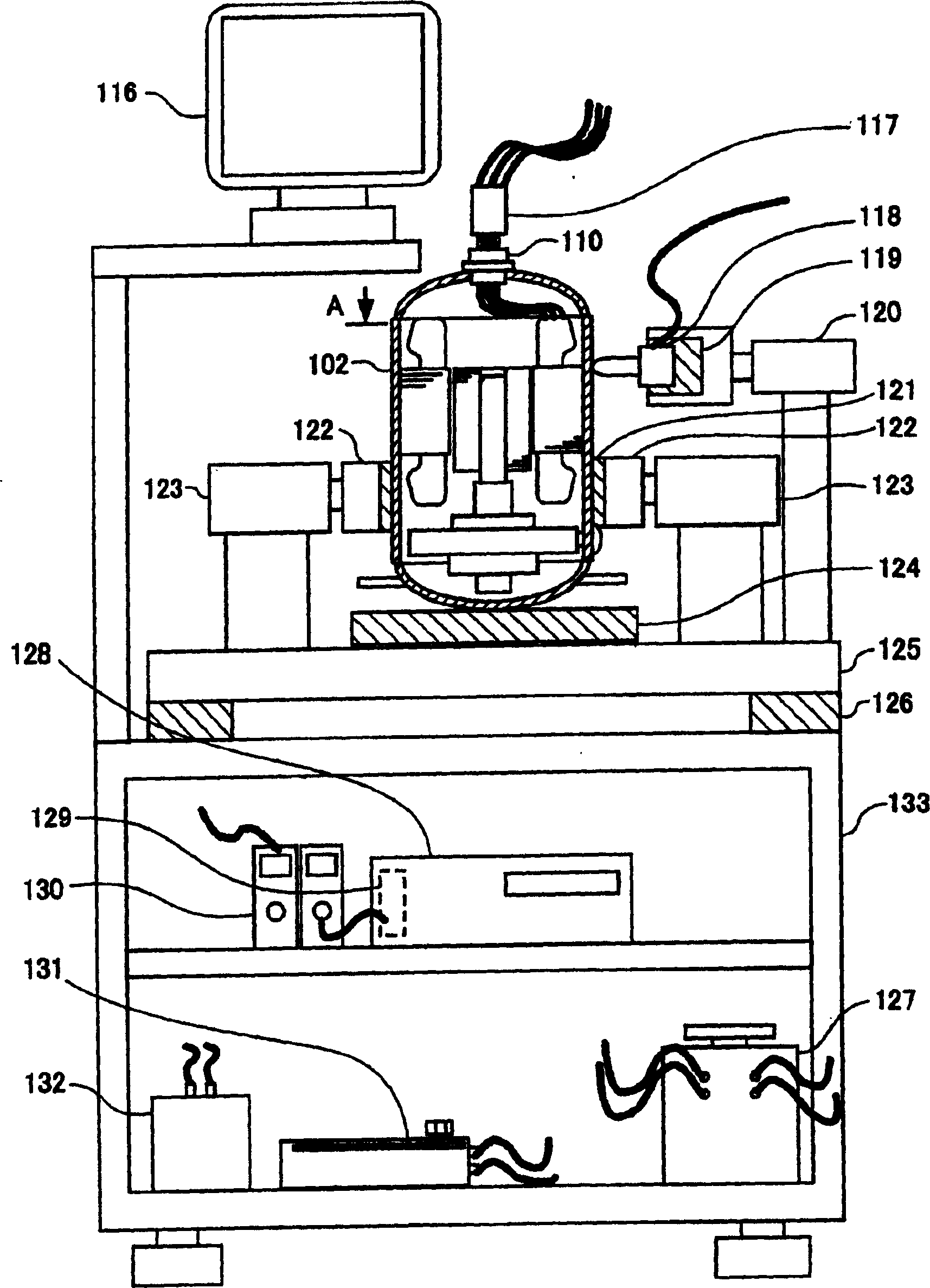

[0054] Referring to the accompanying drawings, the air gap eccentricity inspection method and air gap eccentricity detection device based on the single-phase induction machine of the present invention will be described in detail.

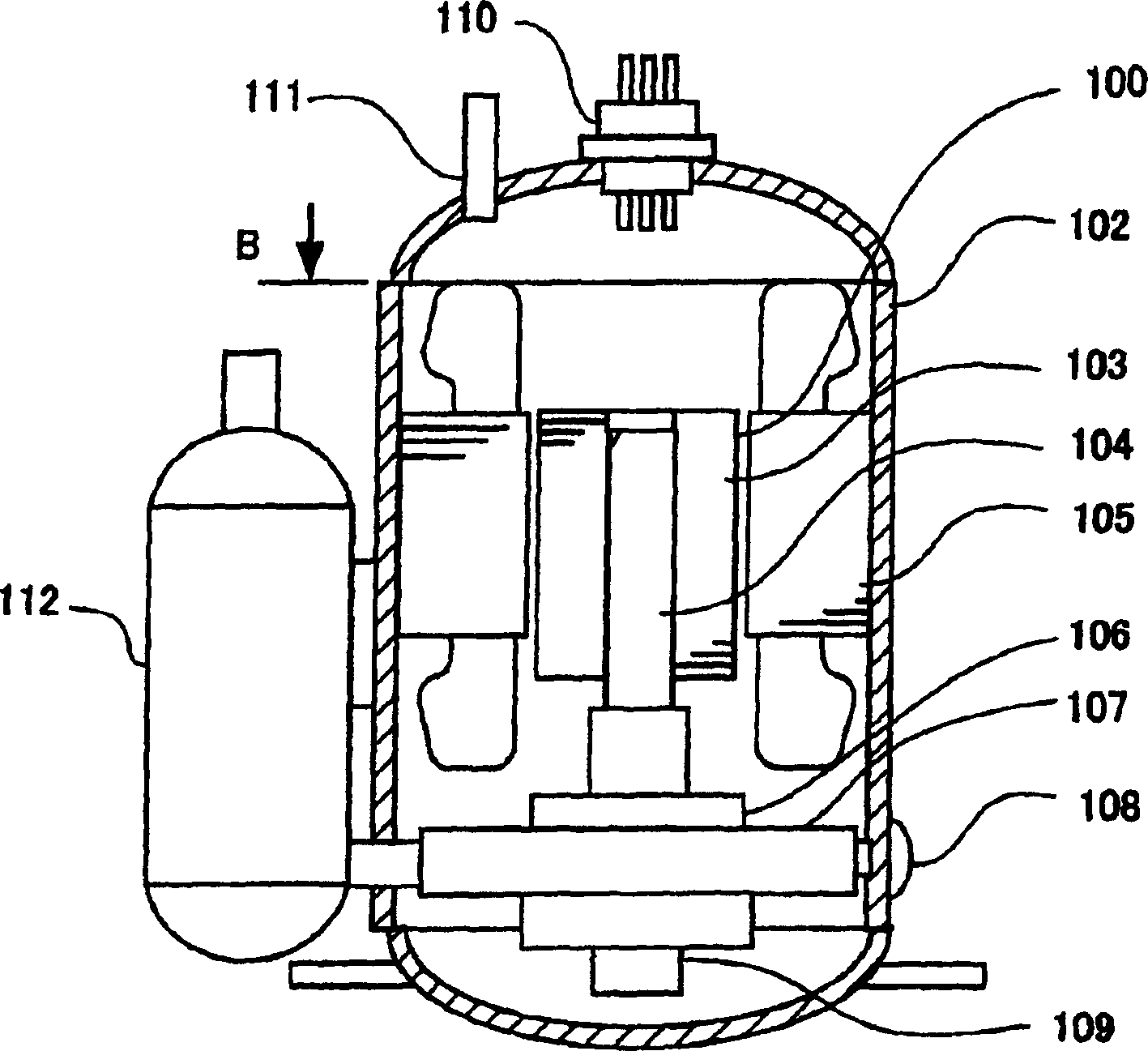

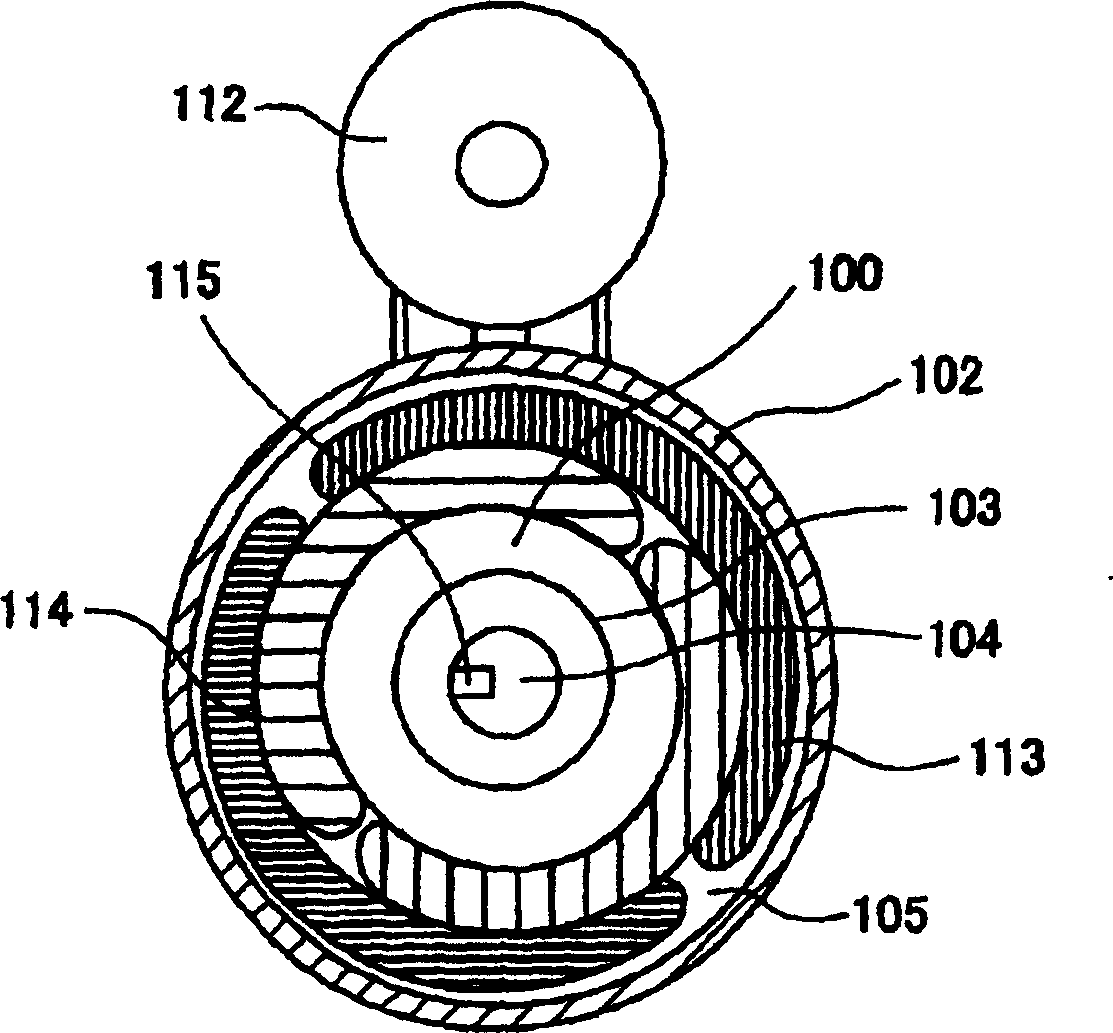

[0055] exist figure 1 shows a longitudinal cross-sectional view of a compressor for refrigeration and air conditioning with a built-in single-phase induction machine as an example of a product to which the present invention is applied. figure 2 From figure 1 The cross-sectional view of the arrow B seen.

[0056] In the drawing, 103 and 105 denote a rotor and a stator which are main components of a single-phase induction machine, and an air gap 100 exists in a cylindrical space between the rotor 103 and the stator 105 . The stator 105 is fixed on the casing 102 as a pressure vessel by sintering, and the rotor 103 and the main shaft 104 are fixed as a whole by sintering. The main shaft 104 is supported by sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com