Method for improving piercing-proof function of high-performance fiber nonwovens with ultrasonic quilting method

A high-performance fiber and non-woven fabric technology, applied in ultrasonic/sonic fiber processing, non-woven fabrics, textiles and papermaking, etc., can solve the problems of difficult to achieve anti-puncture non-woven fabrics, inconvenient users, bloated products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

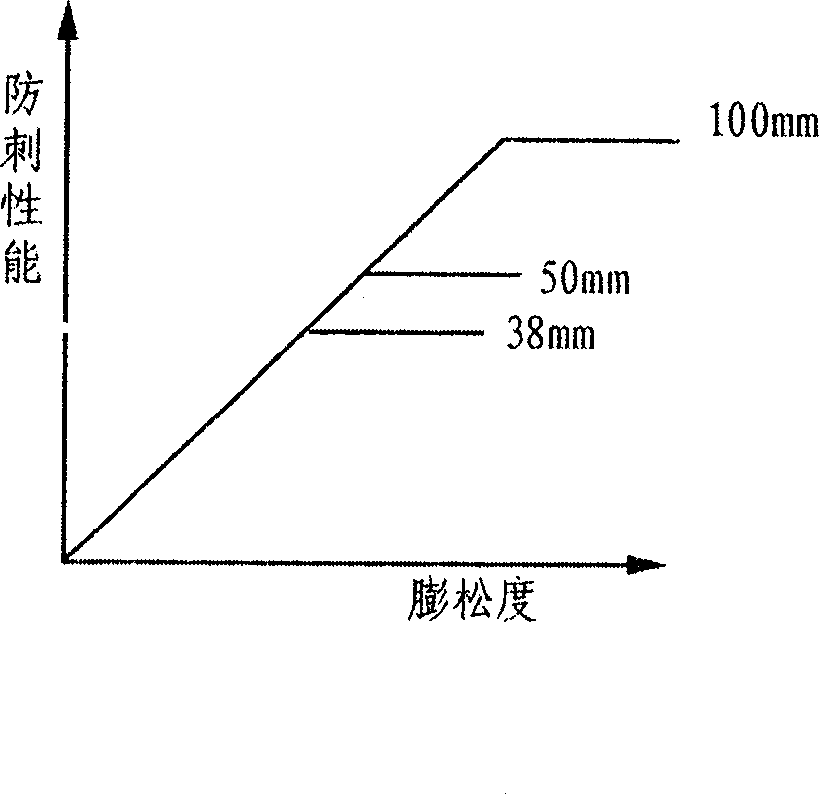

[0014] Embodiment 1: Carry out high-performance fiber nonwoven single-layer composite treatment with the method of the present invention, and the overall density during composite is no more than 600g / m 2 : The high-performance fiber non-woven fabric rolls with a width of 1.5m and a length of 100m are sorted and placed on the unwinding frame of the ultrasonic sewing machine. The ultrasonic sewing machine used has 10 generator heads, and the output power of the generator is 600w× 10. The working frequency is 20Khz, and the non-woven fabric passes through the generating head at 5 m / min. Manually adjust the pressure until the junction is clear. Rolled by roll-forming equipment at the import and export ends, the thickness of the nonwoven fabric sewn by the method of the present invention is reduced by 10%-20%, and the anti-stab performance is improved by about 5% after testing.

Embodiment 2

[0015] Embodiment 2: Carry out double-layer composite treatment of high-performance fiber nonwovens with the method of the present invention, and the overall density during composite is no more than 600g / m 2 : Put 2 rolls of high-performance fiber non-woven fabric rolls with a width of 1.8m and a length of 100m, arrange them on the unwinding frame of the ultrasonic sewing machine, and perform double-layer lamination. The ultrasonic sewing machine adopted has 12 generating heads, the output power of the generator is 600w×12, the working frequency is 20Khz, and the nonwoven fabric passes through the generating heads at 3 m / min. Manually adjust the pressure until the junction is clear. At the import and export end of the line, it is rolled by a roll-forming equipment, and the thickness of the non-woven fabric after stitching is reduced by 15%-25%, and the performance of the test is increased by about 5%.

[0016] The high-performance fiber non-woven fabric roll in the method of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com