Infrared gas analyzer

A gas analyzer, infrared technology, applied in the direction of analyzing materials, material thermal analysis, instruments, etc., can solve the problems of requiring assembly steps, increasing the number of assembly parts, combining complex assembly steps, etc., and achieving the effect of good dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be discussed in detail with reference to the accompanying drawings.

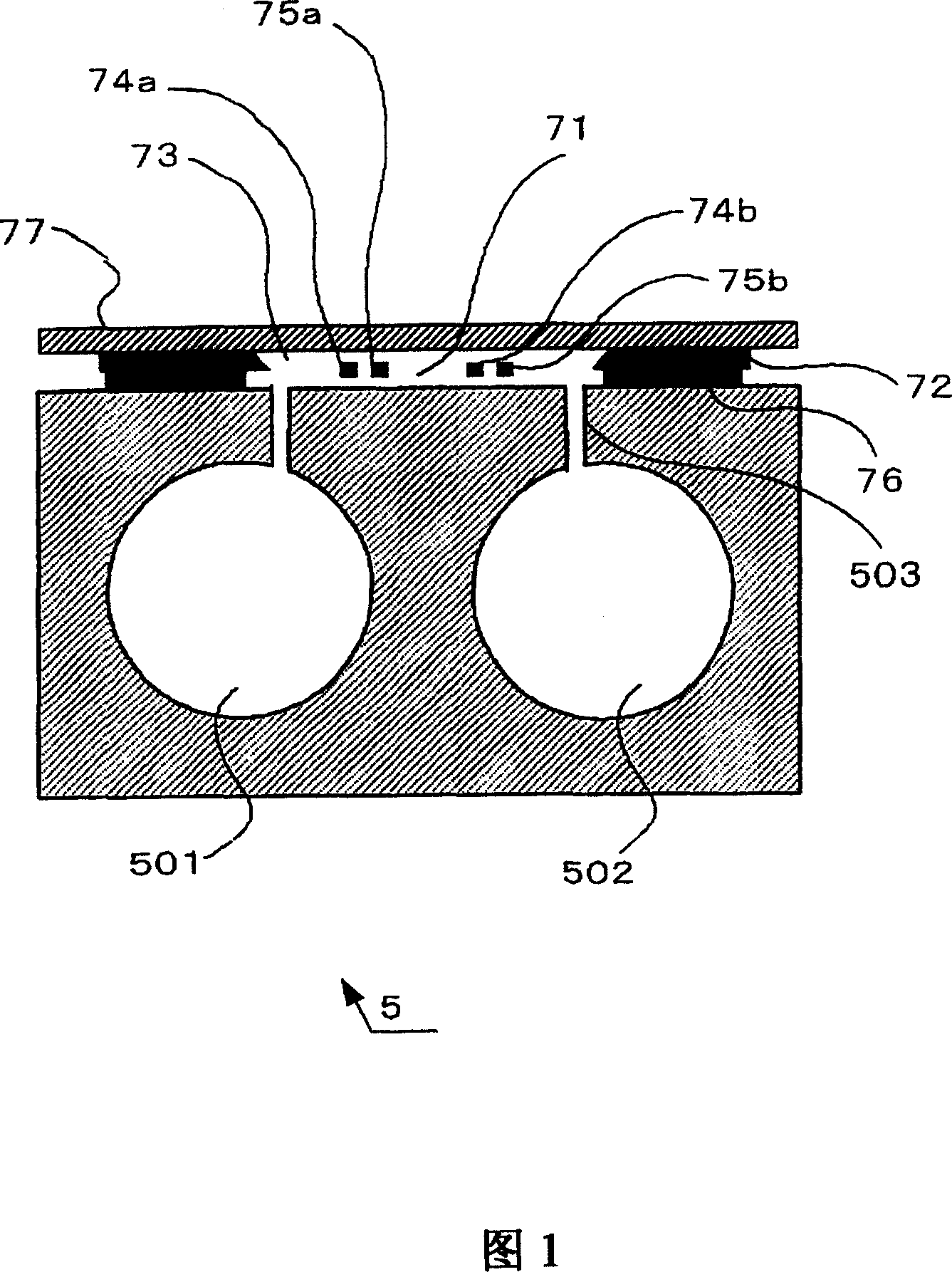

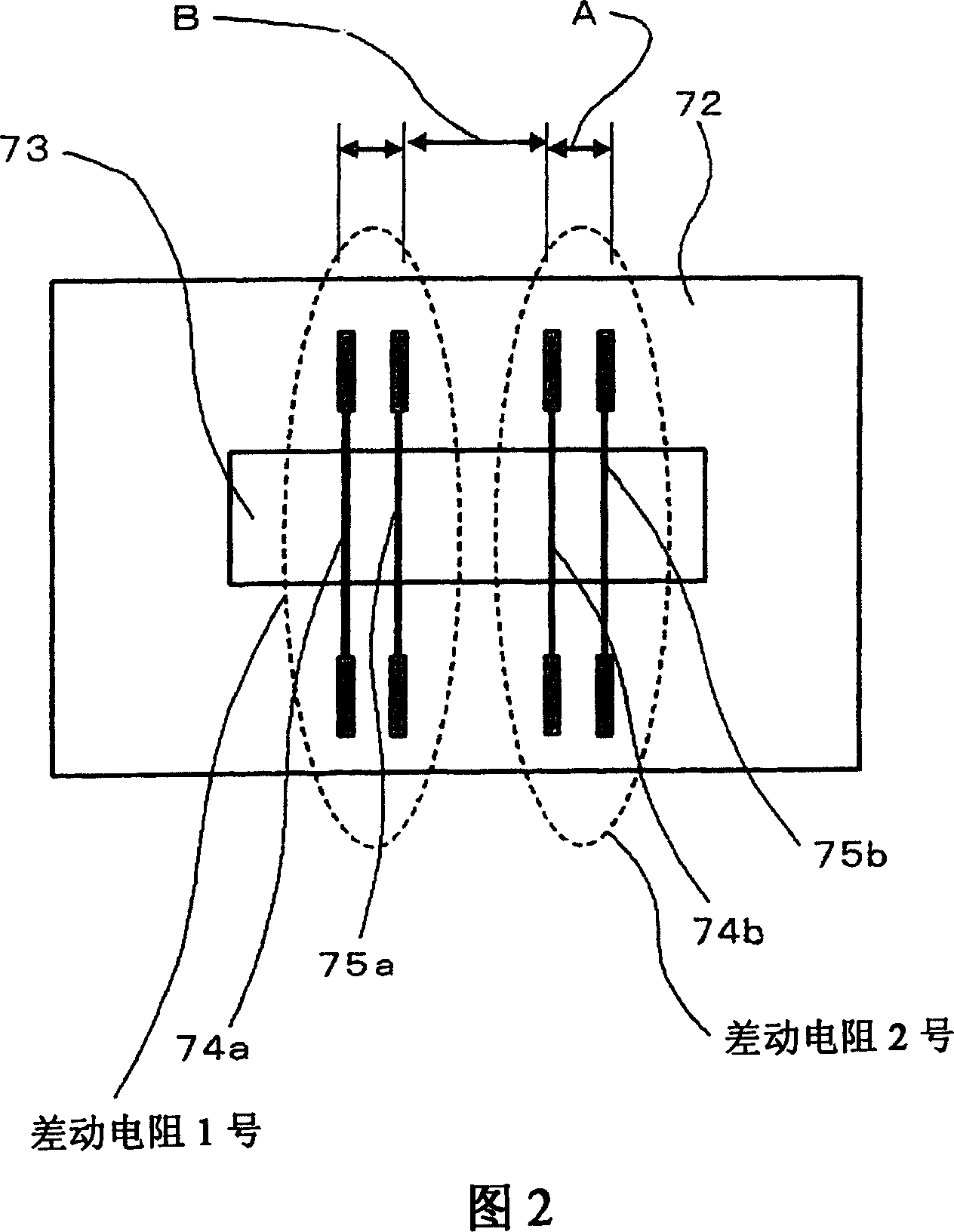

[0078] Fig. 1 is an illustration of the main part configuration of an embodiment of the present invention, and Fig. 2 is

[0079] A detailed illustration of the main parts in Figure 1, where two pairs of heating resistors are used.

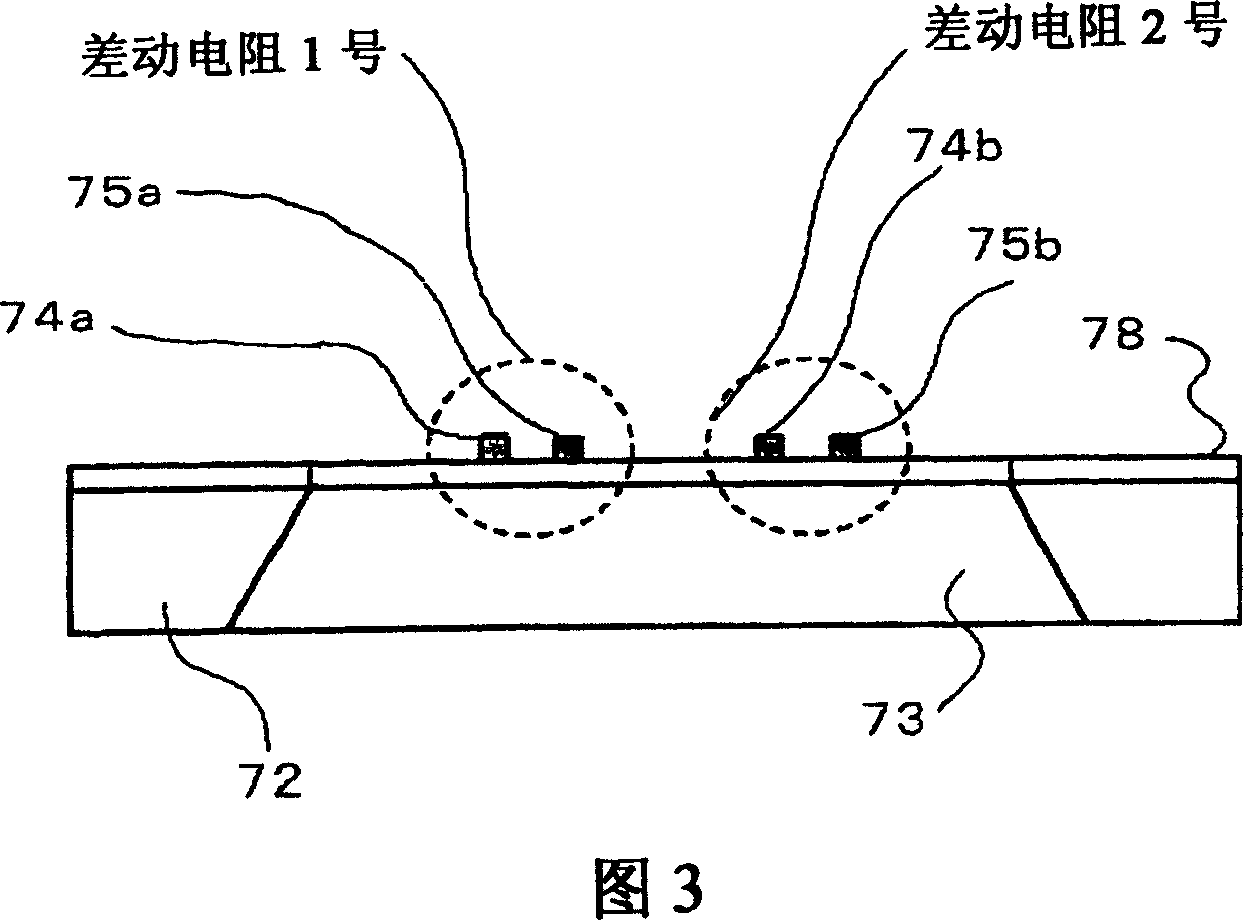

[0080] Fig. 3 is a side view of Fig. 2, and Fig. 4 is a diagram showing a usage example of Fig. 2,

[0081] And FIG. 5 is an operation diagram of FIG. 2 . In Figures 1 to 5 those with respect to Figures 8 and 11 and

[0082] The same parts as previously described are denoted by the same reference numerals.

[0083] Only the differences from the relevant process examples in Figures 8 and 11 will be discussed below:

[0084] The flow channel 71 is provided parallel to one side of the detector 5 .

[0085] The base 72 has a flat plate placed parallel to the airflow direction of the airflow channel 71 .

[0086] Holes 73 are made in the flat p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com