Surface acoustic wave element and method for making same

A surface acoustic wave and component technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems that the insertion loss of surface acoustic wave components cannot be effectively reduced, and achieve the effect of improving design freedom, long overlapping length, and reducing insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

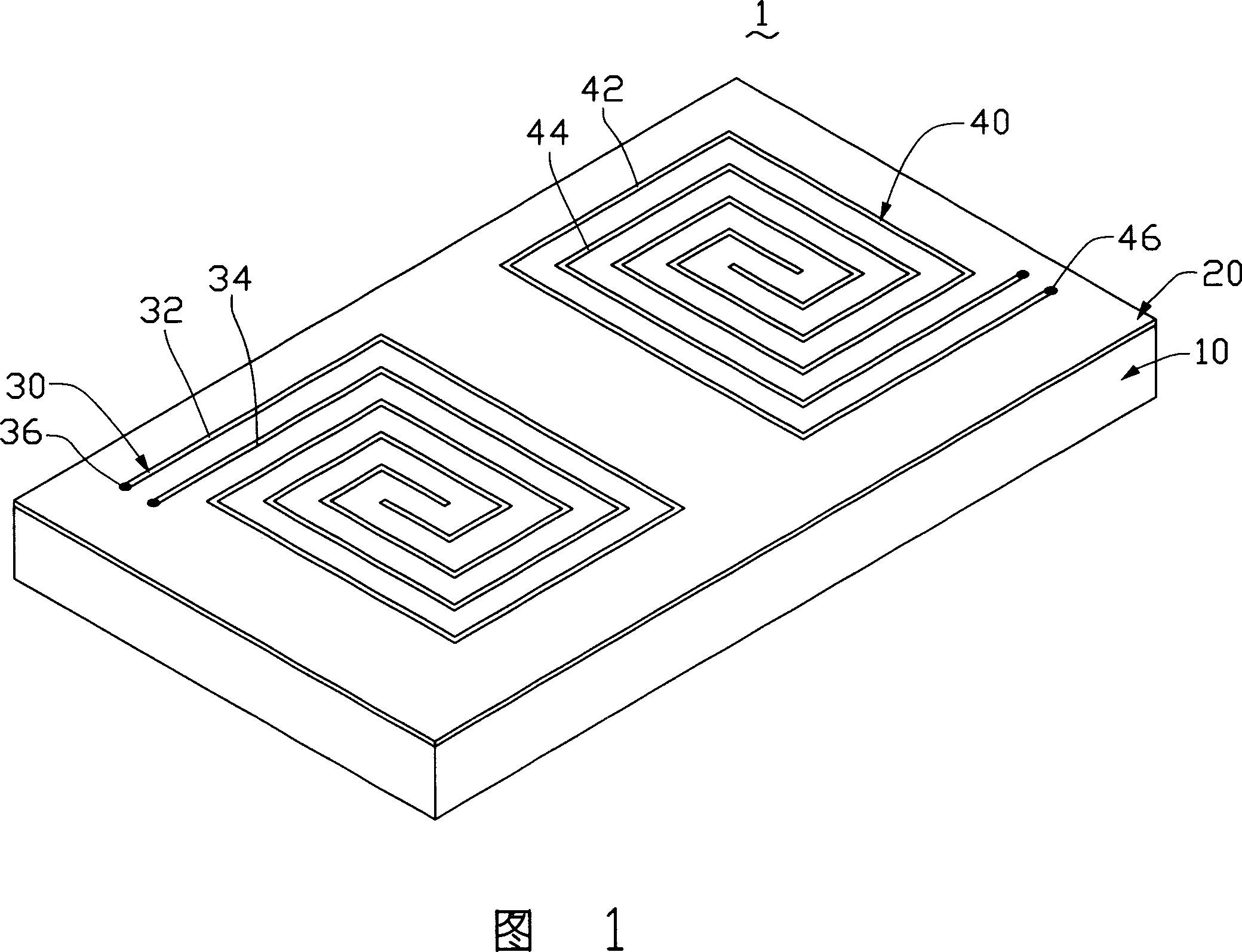

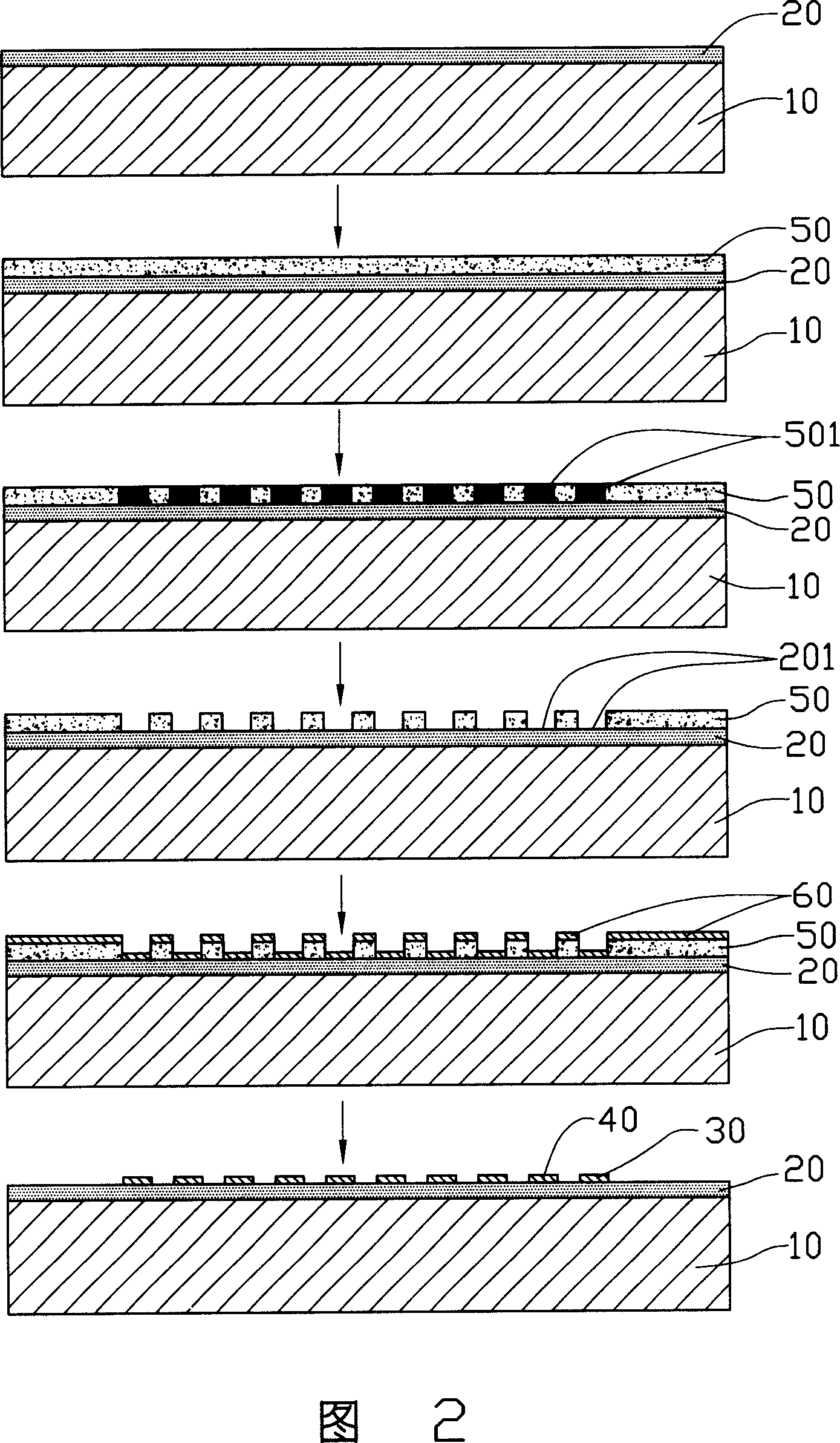

[0011] A preferred embodiment of the present invention discloses a surface acoustic wave device 1 , please refer to FIG. 1 , the surface acoustic wave device 1 includes a substrate 10 , a piezoelectric film layer 20 , a first transducer 30 and a second transducer 40 . The substrate 10 is made of silicon material, and the piezoelectric film layer 20 is formed on the upper surface of the substrate 10. The piezoelectric film layer 20 is made of zinc oxide (ZnOx), lithium niobate (LiNbOx), lithium titanate ( LiTiOx) or lithium tantalate (LiTaOx) and other materials, the first transducer 30 has two opposite electrodes 32,34 and an electrical signal input terminal 36, the material of the two electrodes 32,34 can be gold, silver, copper or Aluminum, which are juxtaposed with each other to form a spiral shape, and the electrical signal input terminal 36 is located at one terminal of the two electrodes 32 , 34 . Wherein, the distance between adjacent two opposite electrodes is preferab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com