Process for printing picture and character on silica gel surface

A technology of silica gel and graphics, applied in the process of producing decorative surface effects, post-processing of printing, printing of special varieties of printed matter, etc., can solve the problem of poor image adhesion, difficult image, text printing, no Solve the problems of silicone products and achieve the effect of not easy to fade and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

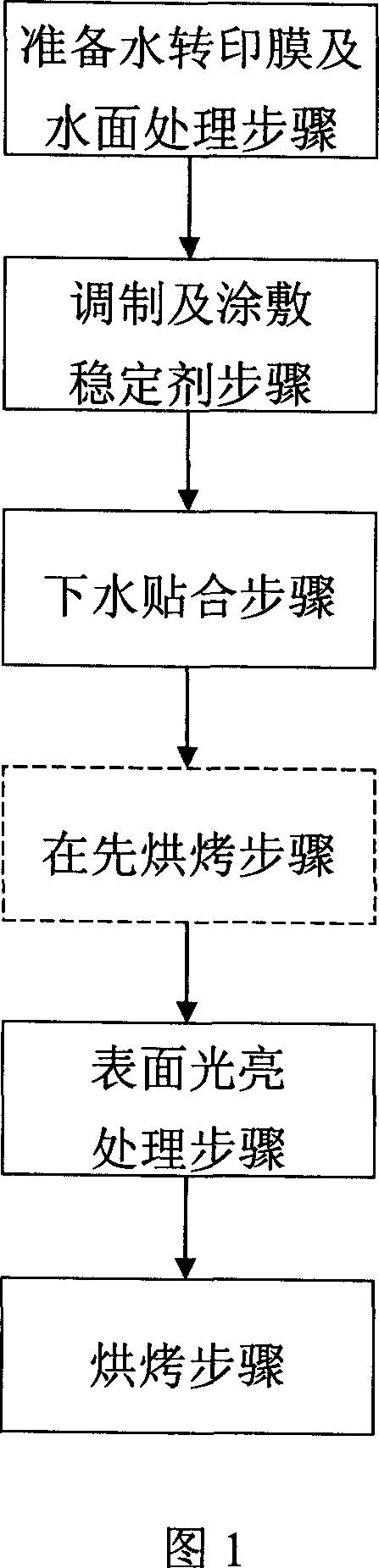

[0019] As shown in Figure 1, the present invention provides a method for printing graphics on the surface of silica gel, comprising the following steps:

[0020] Prepare the water transfer printing film and water surface treatment steps, place the predetermined water transfer printing film on the water surface for treatment;

[0021] Steps of preparing and applying a stabilizer, the stabilizer includes the following components: silicone ink, silicone solvent, diluent, ink stabilization aid for printing, mix the components according to the formula, and apply them on the surface of the water transfer printing film;

[0022] In the water bonding step, the side of the water transfer film coated with the stabilizer is closely attached to the surface of the silicone product;

[0023] The surface brightening treatment step is to perform surface brightening treatment on the silica gel with the water transfer film on the surface to have a beautiful surface;

[0024] The baking step is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com