Agitating device for asphalt Matrix mixing material transferring vehicle

A technology of asphalt mastic and mixing device, which is applied in the directions of roads, road repair, roads, etc., to achieve the effects of high output power, good versatility and avoiding system complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

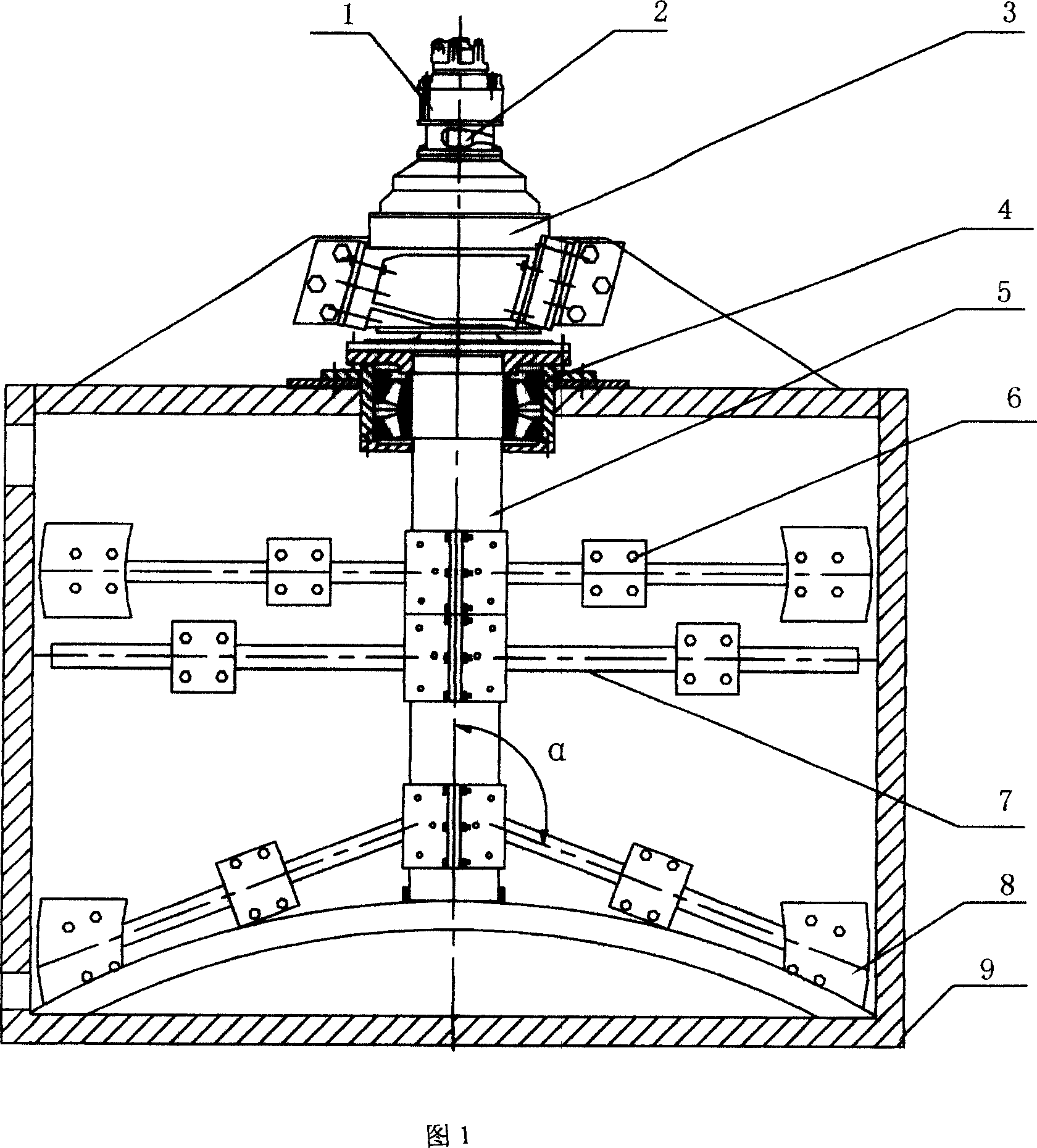

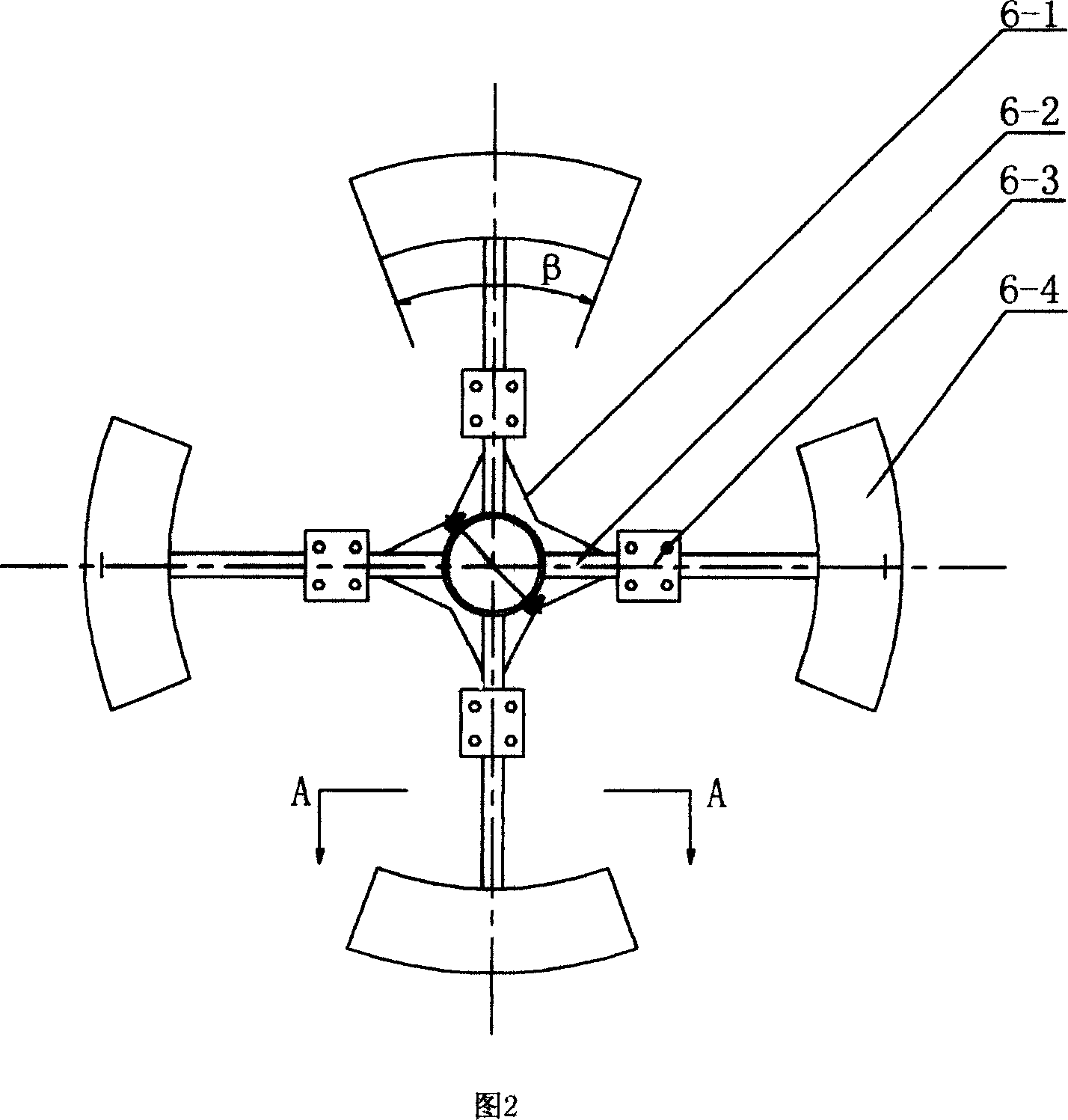

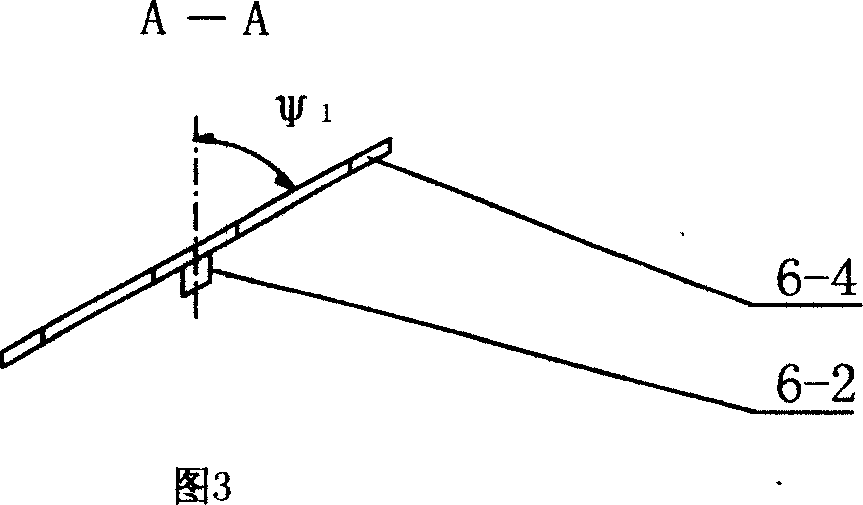

[0028] In this embodiment, the upper stirring impeller 6 is fixedly connected to the upper part of the stirring shaft 5 with a threaded fastening joint, the middle stirring impeller 7 is fixedly connected to the middle part with a threaded fastening joint, and the lower end is fixedly connected with a threaded fastening joint. Lower stirring impeller 8. The outer edge of the upper wheel disc 6-1 is uniformly distributed and fixedly connected with four upper spokes 6-2 in the same plane with threaded fastening connectors, and one upper spoke 6-2 is clamped with the adjacent upper spoke 6-2. The angle is 90°, the angle ψ between the upper surface of the upper spoke 6-2 and the horizontal plane 1 is 10°, the shape of the upper large blade 6-4 installed on the upper surface outer end of the last spoke 6-2 is a circular plate with a central angle β of 30°, and the angle between the upper large blade 6-4 and the horizontal plane is 10° , the shape of the upper small blade 6-3 insta...

Embodiment 3

[0032] In this embodiment, the upper stirring impeller 6 is fixedly connected to the upper part of the stirring shaft 5 with a threaded fastening joint, the middle stirring impeller 7 is fixedly connected to the middle part with a threaded fastening joint, and the lower end is fixedly connected with a threaded fastening joint. Lower stirring impeller 8. The outer edge of the upper wheel disc 6-1 is uniformly distributed and fixedly connected with four upper spokes 6-2 in the same plane with threaded fastening connectors, and one upper spoke 6-2 is clamped with the adjacent upper spoke 6-2. The angle is 90°, the angle ψ between the upper surface of the upper spoke 6-2 and the horizontal plane 1 is 30 °, the shape of the upper large blade 6-4 installed on the upper surface outer end of the last spoke 6-2 is a circular ring plate with a central angle β, and the angle between the upper large blade 6-4 and the horizontal plane is 30 ° , the shape of the upper small blade 6-3 insta...

Embodiment 4

[0036] In the above embodiments 1-3, the outer edge of the upper wheel disc 6-1 is fixedly connected with two upper spokes 6-2 that can equally divide the circumference with a threaded fastening connector in the same plane, and the ends of the upper spokes 6-2 The upper large blade 6-4 of the part is a circular plate with a central angle β of 60°, and the outer edge of the middle disc 7-1 in the middle of the stirring shaft 5 is fixedly connected in the same plane with a threaded fastening connector. 2 middle spokes 7-2 of the divided circumference, and the outer edge of the lower wheel disc 8-1 are fixedly connected with two lower spokes 8-2 that can equally divide the circumference with a threaded fastening connector in the same plane, and the lower spokes 8-2 The lower large blade 8-4 of 2 ends is that the central angle θ is a 45 ° circular ring-shaped plate. The other components and the coupling relationship of the components are the same as those in the corresponding embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com