an automatic cooking machine

An automatic cooking and wire reel technology, which is applied to cooking utensils, induction heating, kitchen utensils, etc., can solve the problems of tumbling food shapes, overheating at the bottom, insufficient heating and undercooking, etc., and achieve high installation and production efficiency, reliable three-dimensional Heating to ensure the effect of heating and curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

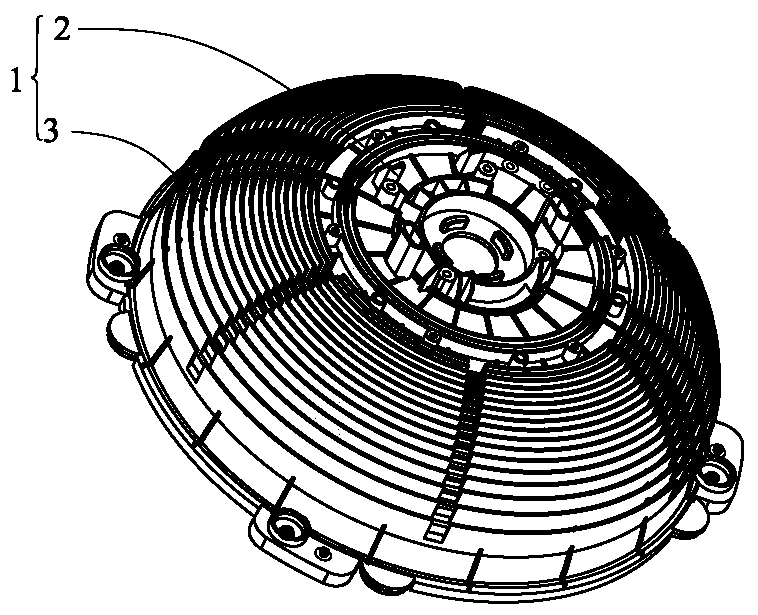

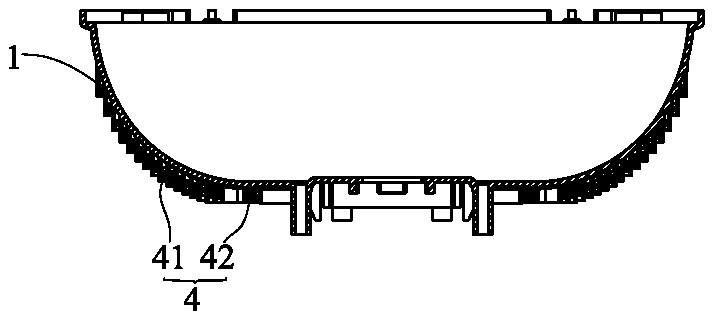

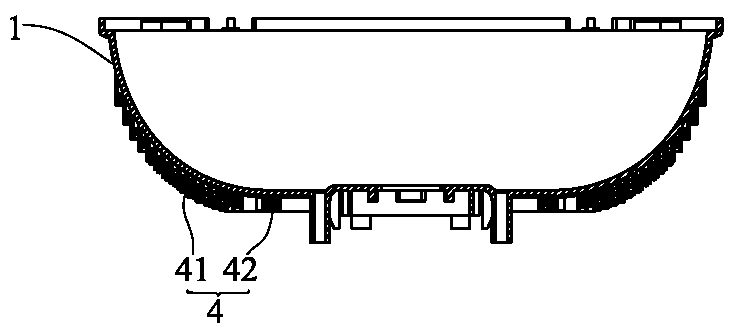

[0028] Such as figure 1 , figure 2 As shown, the first embodiment of an electromagnetic induction coil in the present invention includes: a coil body 1, the coil body includes a bottom wall 2 and an upwardly extending arc-shaped side wall 3; a coil winding 4, the coil The winding 4 includes a side induction coil 41 and a bottom induction coil 42; the coil winding 4 is wound on the wire disc body 1, the number of turns of the side induction coil 41 is greater than the number of turns of the bottom induction coil 42, and the bottom induction coil is arranged on the bottom wall peripheral.

[0029] In this embodiment, the cable tray body 1 is integrally formed and has a hemispherical shape as a whole, including a bottom wall 2 and an arc-shaped side wall 3 extending upward. The coil body is provided with a winding slot corresponding to the coil winding, and the number of turns of the side induction coil in the winding slot is greater than the number of turns of the bottom indu...

Embodiment approach 2

[0045] see image 3 As shown, the second embodiment of an electromagnetic induction reel in the present invention differs from the first embodiment in that the number of winding layers of the side induction coil 41 is greater than the number of winding layers of the bottom induction coil 42 .

[0046] In this way, it is further ensured that the arc-shaped side wall of the electromagnetic induction coil of the present invention generates more heat than the bottom wall, thereby ensuring the effect of three-dimensional heating.

[0047] Further, the winding layers of the side induction coil 41 are 2-4 layers, and the winding layers of the bottom induction coil 42 are 1-2 layers. Certainly, when the side induction coil 41 is wound, the number of local layers can also be more, for example, the middle part of the side induction coil 41 has more layers than the two sides, or the layers are arranged alternately. In general, it can ensure that the heat of the side induction coil 41 i...

Embodiment approach 3

[0050] see Figure 4 As shown, an embodiment of an automatic cooking machine of the present invention includes a pot 5 and an electromagnetic induction wire reel, the electromagnetic induction wire reel is located at the bottom of the pot 5, and in the cooking state, the pot 5 and the electromagnetic induction wire The pans are tilted together.

[0051] The electromagnetic induction coil described above is one of the first or second embodiment.

[0052] In this embodiment, the pot 5 includes a bottom wall 51, a side wall 52 and an arc-shaped transition portion 53, and the coil winding on the arc-shaped side wall of the electromagnetic induction coil covers at least 1 / 2 of the arc-shaped transition portion 53 area. In this way, it can effectively ensure that the side induction coil of the electromagnetic induction coil heats the arc-shaped transition portion of the pan to ensure the cooking effect. Further, the side induction coil completely covers the arc-shaped transition p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com