Rapid and sufficient chestnut heating equipment

A fully heating and fast technology, which is applied in the field of fast and fully heating equipment for chestnuts, can solve the problems of uneven quality of chestnuts, loss of staff strength, and low production efficiency, and achieve the effect of fully roasting, uniform quality, and preventing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

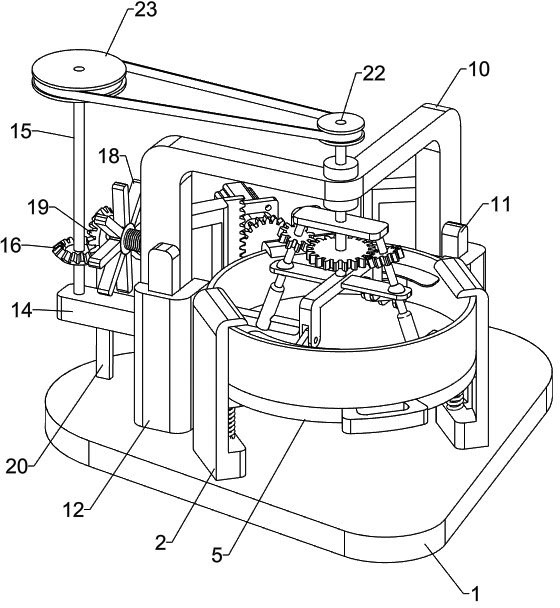

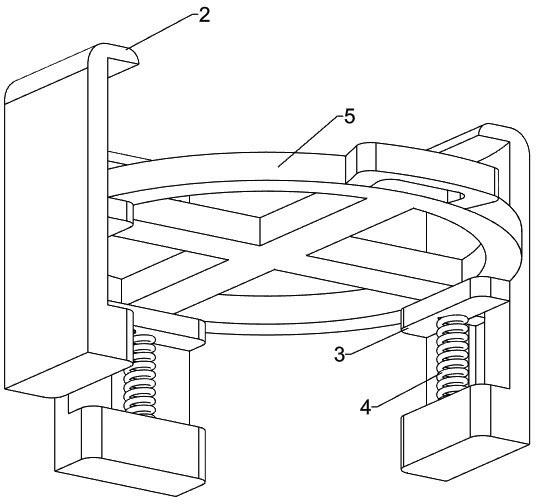

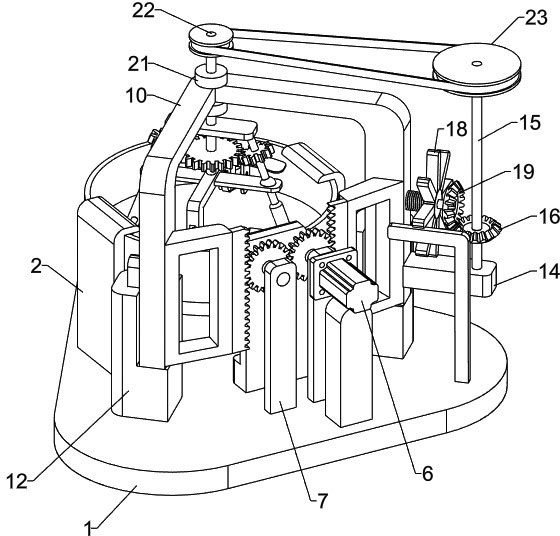

[0055] A device for rapid and sufficient heating of chestnuts, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 ,with Figure 7 As shown, it includes a base 1, a first mounting plate 2, a slide plate 3, a first spring 4, a circular support plate 5, a motor 6, a first bearing seat 7, a first rotating shaft 8, a first spur gear 9, and a support frame 10. Slider 11, second mounting plate 12, rack 13, second bearing seat 14, second rotating shaft 15, first bevel gear 16, third rotating shaft 17, fan wheel 18, second bevel gear 19, toggle Rod 20, third bearing seat 21, fourth rotating shaft 22, transmission assembly 23 and first stirring frame 24, three first mounting plates 2 are connected to the top of the base 1, the inner wall of the first mounting plate 2 is slidably connected to a slide plate 3, and the slide plate The first spring 4 is connected between the top of the 3 top and the bottom wall of the first mounting plate 2, the circular suppor...

Embodiment 2

[0058] On the basis of Example 1, such as Image 6 As shown, a baffle 25 is also included, and both sides of the bottom of the first stirring frame 24 are connected with baffles 25 .

[0059] When the first stirring frame 24 rotated, it drove the baffle plate 25 to rotate, preventing the chestnuts from flying out in the stirring process, causing waste.

[0060] Such as Image 6 As shown, it also includes a second spur gear 26, a fourth bearing seat 27, a second stirring frame 31, a fifth rotating shaft 29, a third spur gear 30 and a fifth bearing seat 28, and the fourth rotating shaft 22 bottom is connected with a second Spur gear 26, the fourth rotating shaft 22 is connected with the fourth bearing seat 27, the fourth bearing seat 27 is located above the second spur gear 26, the first stirring frame 24 is connected with the fifth bearing seat 28, the fourth bearing seat 27 The fifth rotating shaft 29 is rotatably connected between both sides of the bottom and the fifth bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com