Self-declining type circulating ash cooling device and treatment method for circulating ash

A technology of cooling device and circulating ash, applied in the direction of combustion method, combustion type, lighting and heating equipment, etc., can solve the problems of increased tail ash concentration, increased wear of induced draft fan, and decreased furnace temperature, so as to reduce and improve the tail ash concentration. Running performance, effect of reducing inlet concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

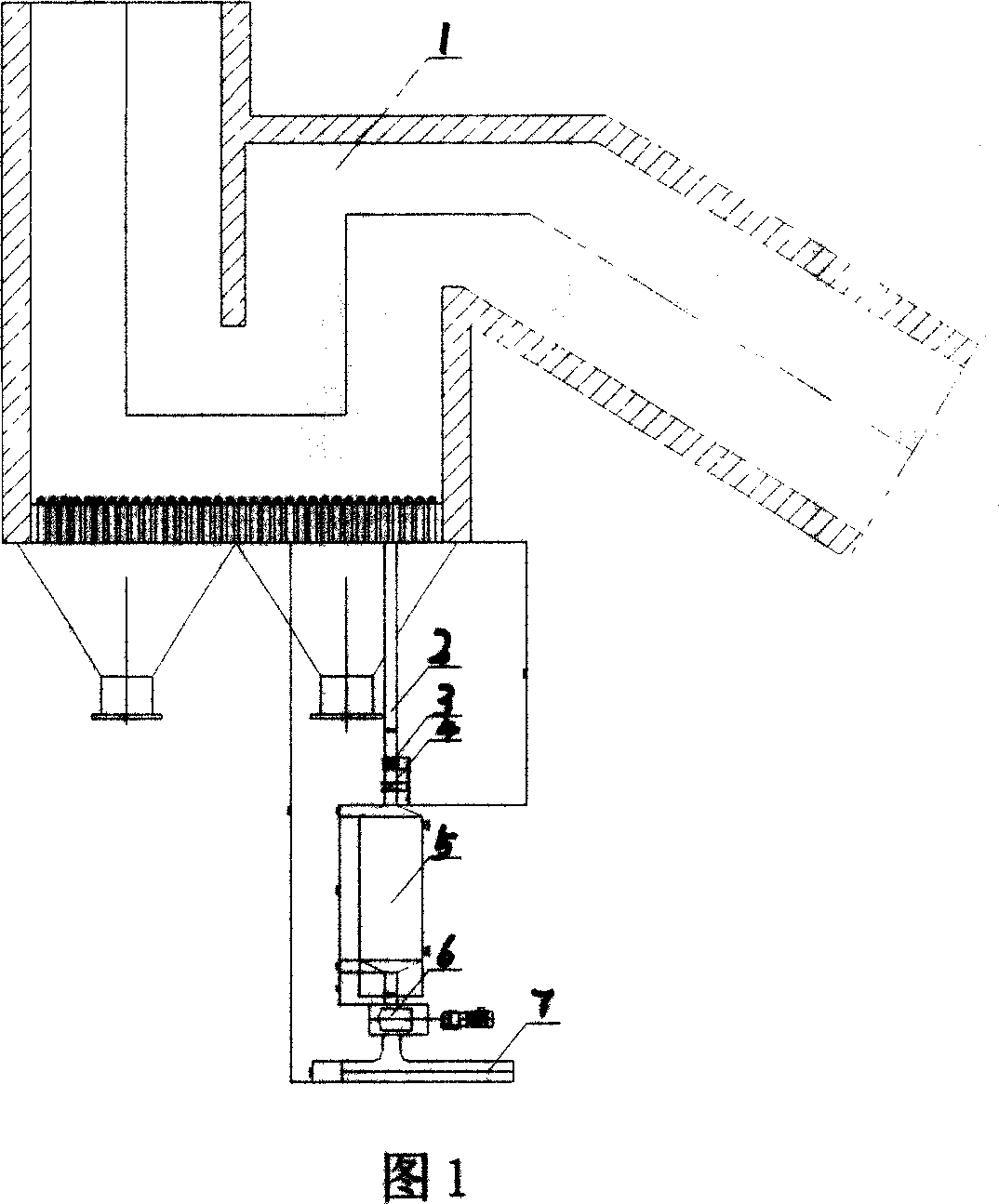

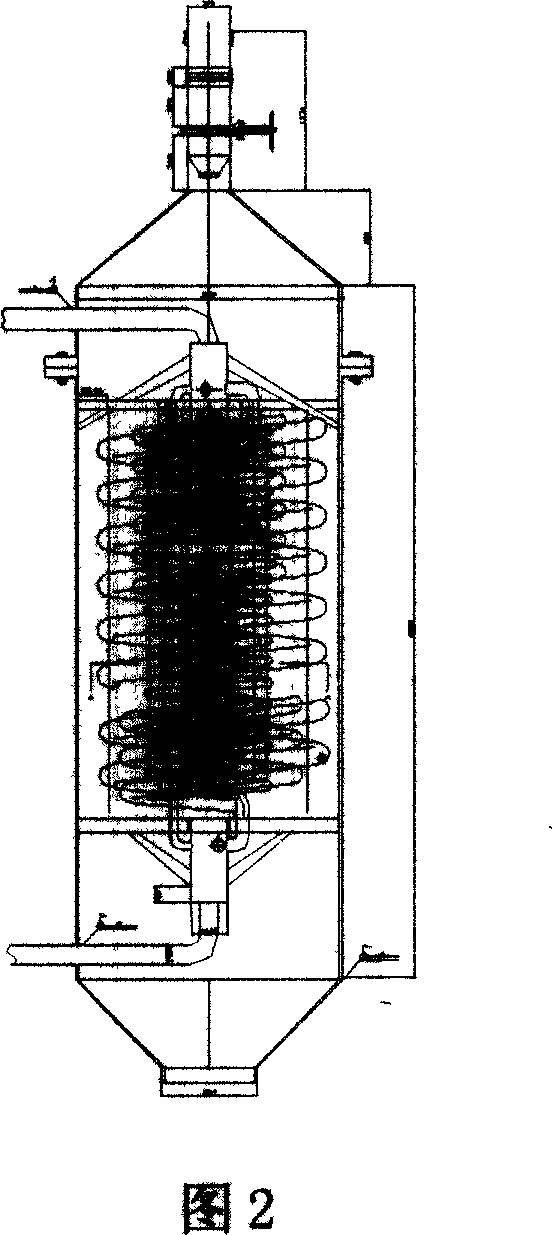

[0010] Referring to Figures 1 and 2, the present invention includes a feeder 1 and an ash discharge pipe 2 arranged at the bottom of the feeder, an expansion joint 3 is arranged on the ash discharge pipe 2, and the inlet of the cooler 5 is connected with the ash discharge through a manual valve 4 The pipe 2 is connected, and the outlet of the cooler 5 is connected with the rotary control valve 6. The heating surface of the cooler 5 adopts a spiral tubular structure. The cooler 5 of this embodiment adopts a coaxially arranged multi-layer spiral tube heating surface. The outlet of the control valve 6 communicates with the pneumatic conveying pipeline 7 .

[0011] The treatment method of the present invention is as follows: firstly open the manual valve 4, and the circulating ash discharged from the feeder 1 enters the cooler 5 through the ash discharge pipe 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com